Pyrolytic carbon interface phase, preparation method and application thereof, carbon fiber reinforced silicon carbide ceramic-based composite material and preparation method thereof

A technology of silicon carbide ceramic matrix and silicon carbide ceramics, which is applied in the field of carbon fiber reinforced silicon carbide ceramic matrix composite materials and its preparation, pyrolytic carbon interface phase and its preparation, and can solve the problem that the mechanical properties of C/SiC ceramic matrix composite materials cannot be provided And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

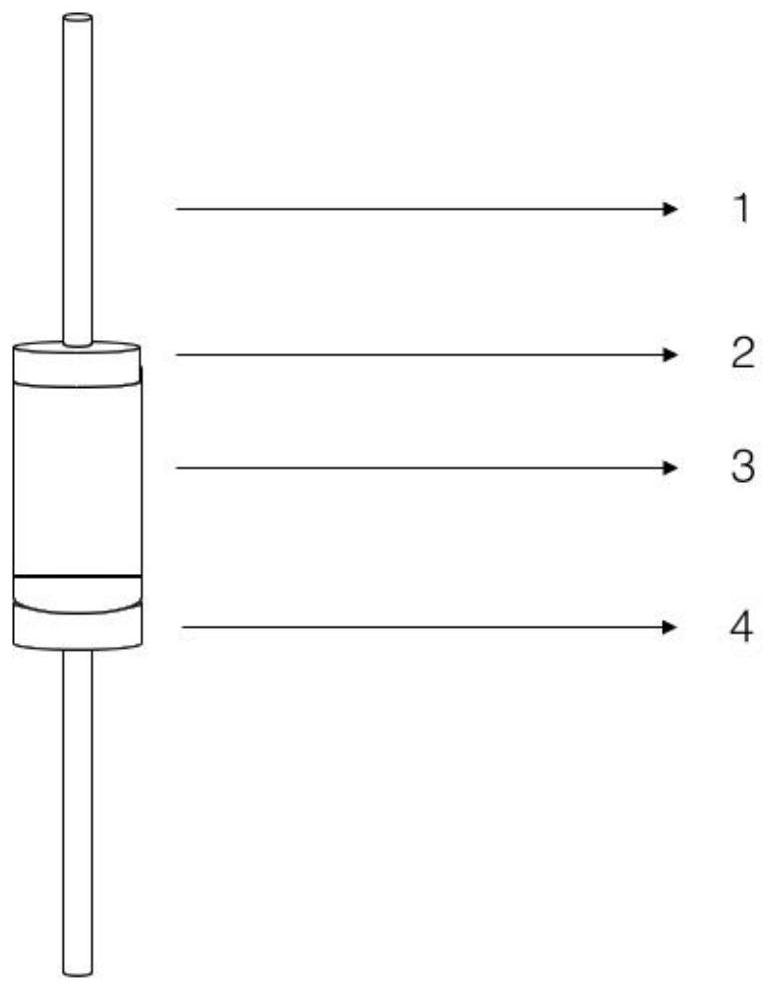

[0038] The invention provides a method for preparing a pyrolytic carbon interface phase, comprising the following steps:

[0039] Provide carbon fiber prefabricated body;

[0040] Using gaseous hydrocarbons as a carbon source, performing chemical vapor phase infiltration on the surface of the carbon fiber preform to form a pyrolytic carbon interface phase on the surface of the carbon fiber preform;

[0041] The chemical vapor deposition includes sequentially performing preheating and deposition;

[0042] The vacuum degree of the preheating is 880-980mbar, the temperature is 1000-1200°C, and the holding time is 2-3h;

[0043] The flow rate of the carbon source in the deposition is 250-750mL / min; the pressure is 30-100mbar, the temperature is 900-1000°C, and the holding time is 2-3h.

[0044] In the present invention, unless otherwise specified, each substance in the preparation method is a commercially available product well known to those skilled in the art.

[0045] The in...

Embodiment 1

[0080] The carbon fiber prefabricated body was prepared with T700-12K carbon fiber produced by Toray, Japan, and placed in the chamber of the chemical vapor infiltration equipment after degluing. After vacuuming, it was filled with argon to 880mbar, and the temperature was raised to 1000°C at a rate of 5°C / min. Insulate for 2 hours for preheating, then stop feeding argon, use propylene as the hydrocarbon gaseous precursor, keep the ambient pressure in the chamber at 30mbar, deposit at 950°C for 2 hours, and form a pyrolytic carbon interface phase on the surface of the carbon fiber preform.

Embodiment 2

[0087] The carbon fiber prefabricated body was prepared with T700-12K carbon fiber produced by Toray, Japan, and placed in the chamber of the chemical vapor infiltration equipment after degluing. After vacuuming, it was filled with argon to 880mbar, and the temperature was raised to 1000°C at a rate of 5°C / min. Insulate for 2 hours for preheating, then stop feeding argon, use propylene as the hydrocarbon gaseous precursor, keep the ambient pressure in the chamber at 100mbar, deposit at 950°C for 2 hours, and form a pyrolytic carbon interface phase on the surface of the carbon fiber preform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com