Aggregate material, non-metal current collector and preparation method and application of non-metal current collector

A current collector and aggregate technology, applied in the field of aggregate materials, can solve the problems of low mechanical strength, difficult to apply to lithium ion batteries, etc., and achieve the effects of good electrical conductivity, damage prevention and mechanical strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] A lithium battery current collector, which includes a polymer aggregate and a modified carbon fiber layer on the surface;

[0112] The polymer fiber aggregate is composed of natural wood pulp fibers (5-20 μm in length), conductive agent (carbon nanotubes), and dispersant polyacrylamide, and the mass ratio of the three is 80:18:2;

[0113] The modified carbon fiber layer is composed of polypropylene fiber (1-5 μm in length), activated carbon fiber (3-20 μm in diameter, 5-20 μm in length), heteroatom precursor and polyacrylamide (binder), with a mass ratio of 10 :88:2:2; The heteroatom precursor is selected from aniline.

[0114] A kind of current collector of lithium battery, its preparation method comprises the following steps:

[0115] 1) Referring to Table 1, the wood pulp fiber (component A in the polymer aggregate) is air-dried and broken into individual fibers by a crusher, and then transported to the wood pulp former, and the conductive agent (component A in the ...

Embodiment 2-8、 comparative example 1-2

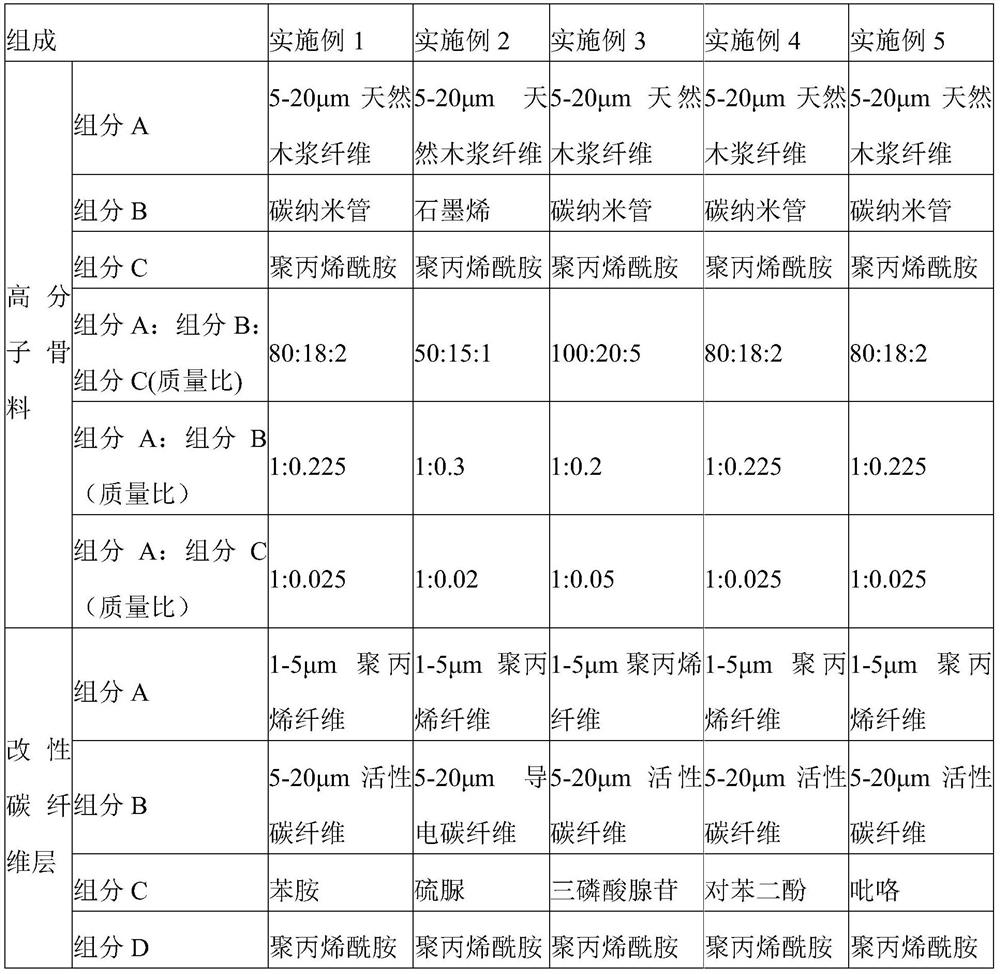

[0121] Concrete components and process are shown in Table 1 and Table 2 below, and all the other steps are the same as in Example 1.

[0122] Table 1

[0123]

[0124]

[0125] Note: The dimensions of natural wood pulp fibers, polypropylene fibers, activated carbon fibers and conductive carbon fibers in Table 1 refer to the length.

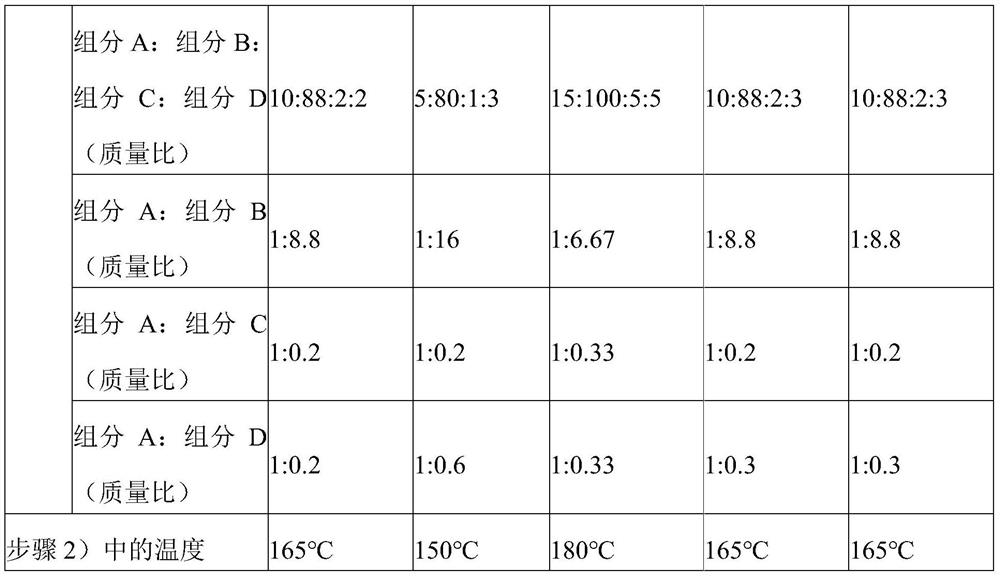

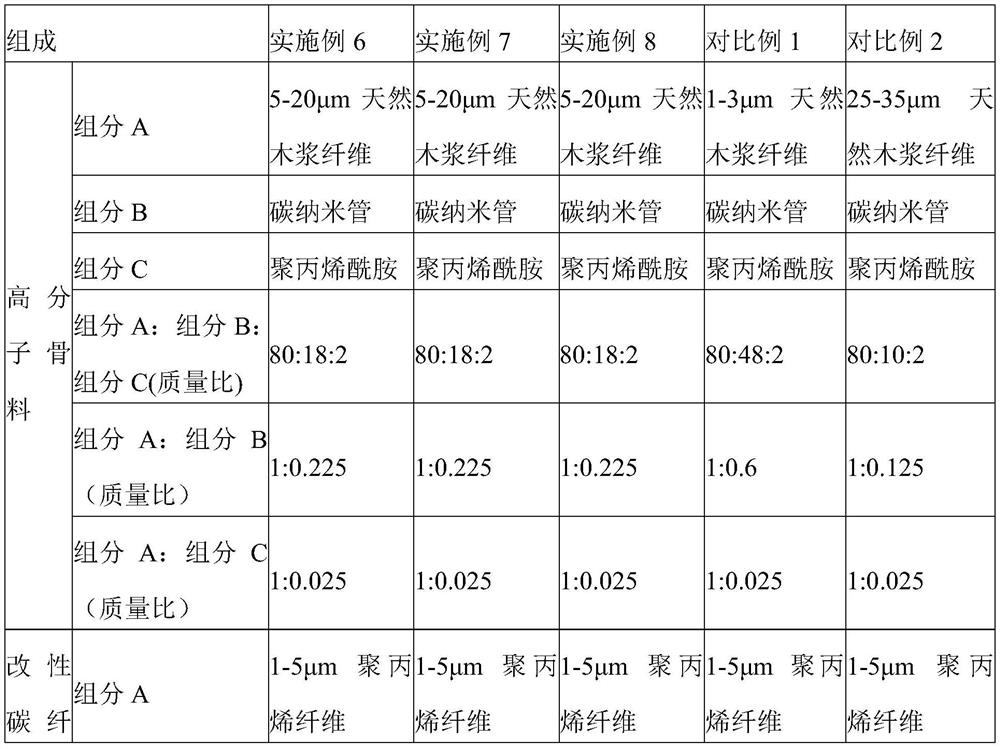

[0126] Table 2

[0127]

[0128]

[0129] Note: The dimensions of natural wood pulp fibers, polypropylene fibers, activated carbon fibers and conductive carbon fibers in Table 2 refer to the length; " / " means that this component is not added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com