Detector for detecting when the thread bobbin in a thread-processing system has to be replaced

A technology for processing systems and monitors, applied in the field of monitors, can solve problems such as pollution of photoelectric monitors, and achieve the effect of eliminating the danger of yarn damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

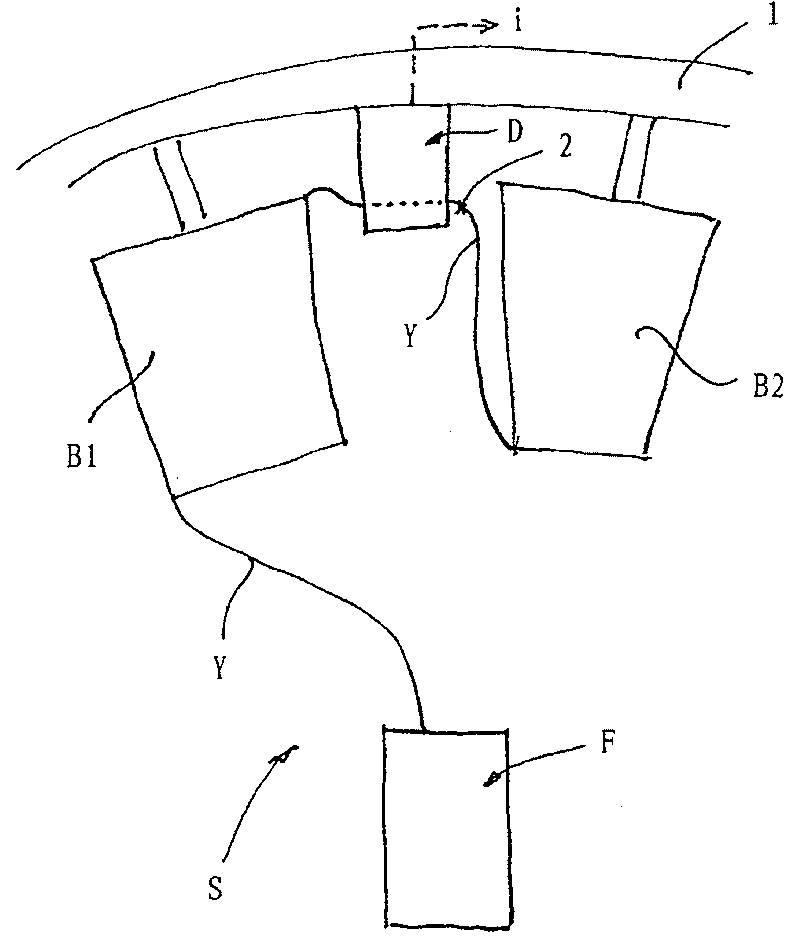

[0029] Such as figure 1, in a yarn processing system S, two bobbins B1, B2 carrying the same yarn Y are mounted on creel 1, for example. A yarn processing device F, such as a yarn feeding device, draws yarn Y from said respective yarn bobbins B1, B2. The end of the yarn Y on one yarn bobbin B1 is connected by a knot to the front end of the yarn Y on the other yarn bobbin B2 (pigtail). For example, on the creel 1, a monitor D is installed at the position where the connection portion of the yarn Y is located.

[0030] When the yarn Y is exhausted from the yarn spool B1, the second yarn spool B2 produces a yarn spool change. During the changeover, the connection is pulled out of the monitor D before the yarn Y is thereafter withdrawn from the second yarn spool B2. During this transformation, the monitor D generates a signal i indicative of the transformation that has taken place. In some cases, the monitor D is designed such that during loading of the yarn Y to the monitor D,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com