Method for preparing lanthanum titanate crystal by vertical zone melting descent method

A technology of vertical zone melting and lanthanum titanate, which is applied in the direction of self-zone melting, crystal growth, chemical instruments and methods, etc., can solve the problems of high production cost, melting of lanthanum titanate raw materials, large energy consumption, etc., and achieve improved transmission The rate of mass and heat transfer, the effect of improving purity and yield, and ensuring yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 provides a kind of method for vertical melting drop method to prepare lanthanum titanate crystal, comprises the following steps:

[0038] (1) TiO 2 and La 2 o 3 The initial raw material is La 2 Ti 2 o 7 Chemical composition ingredients, after mixing uniformly, a mixture is obtained;

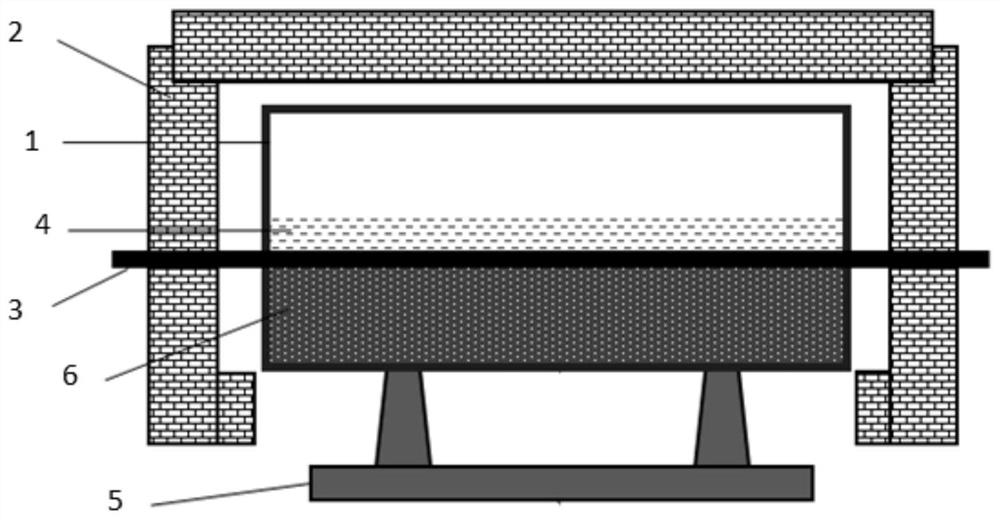

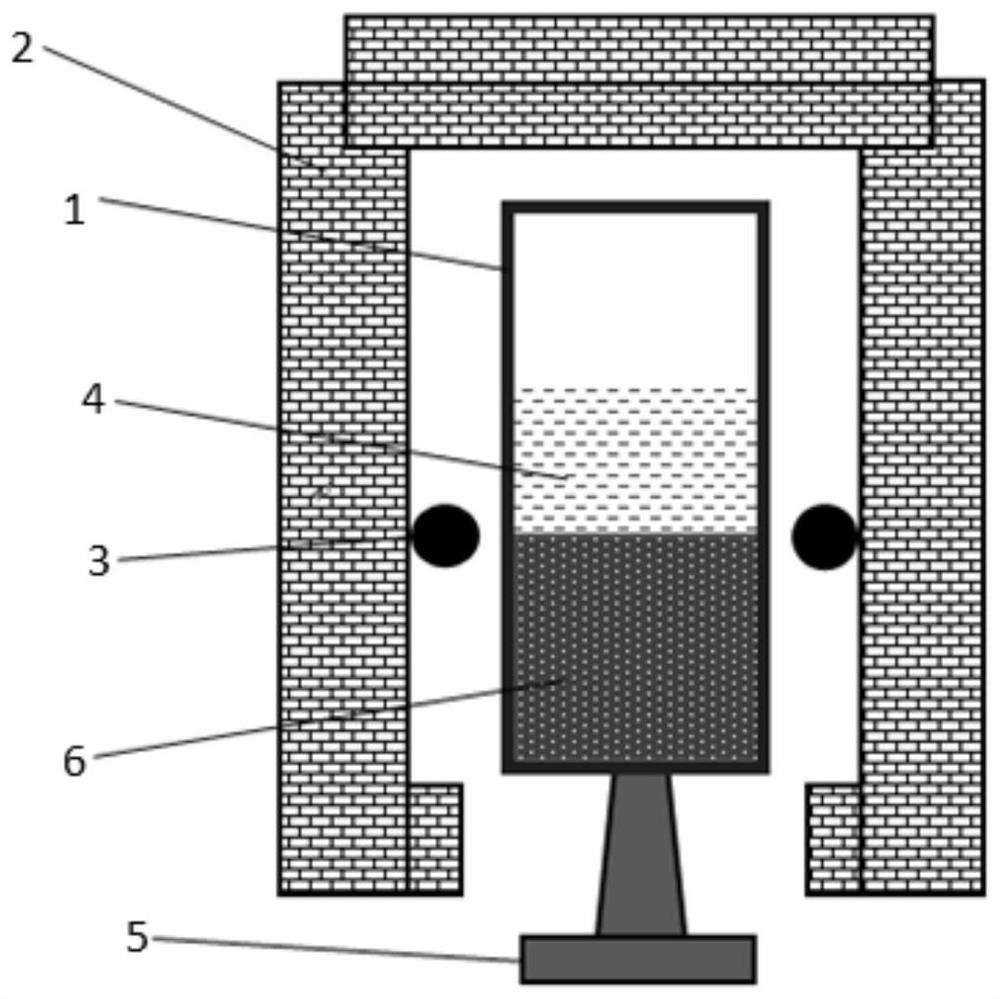

[0039] (2) placing the molybdenum crucible 1 of the mixture described in step (1) in the vacuum crystal furnace 2;

[0040] (3) Vacuumize the vacuum crystal furnace 2, heat it to 1500°C and fill it with argon gas, then continue to heat up to 1900°C, after 8 hours of heat preservation, open the lifting mechanism 5, adjust the height of the crucible, so that the molybdenum crucible 1 is 0.5mm / The hourly speed gradually decreases, the melt 4 in the crucible 1 is solidified into a crystal 6 through the temperature gradient of 30°C / cm in the furnace cavity, and the vacuum crystal furnace lowers the furnace temperature to room temperature at a speed of 30°C / h to obtain the ti...

Embodiment 2

[0045] Embodiment 2 provides a kind of method for vertical melting drop method to prepare lanthanum titanate crystal, comprises the following steps:

[0046] (1) TiO 2 and La 2 o 3 The initial raw material is La 2 Ti 2 o 7 Chemical composition ingredients, after mixing uniformly, a mixture is obtained;

[0047] (2) placing the molybdenum crucible 1 of the mixture described in step (1) in the vacuum crystal furnace 2;

[0048] (3) Vacuumize the vacuum crystal furnace 2, heat it to 1600°C and fill it with argon gas, then continue to heat up to 1920°C, after 8 hours of heat preservation, open the lifting mechanism 5, adjust the height of the crucible, so that the molybdenum crucible 1 is 1.5mm / The hourly rate gradually decreases, the melt 4 in the crucible 1 is solidified into crystal 6 through the temperature gradient of 40°C / cm in the furnace cavity, and the vacuum crystal furnace lowers the furnace temperature to room temperature at a speed of 40°C / h to obtain the titan...

Embodiment 3

[0053] Embodiment 3 provides a kind of method for vertical melting drop method to prepare lanthanum titanate crystal, comprises the following steps:

[0054] (1) TiO 2 and La 2 o 3 The initial raw material is La 2 Ti 2 o 7 Chemical composition ingredients, after mixing uniformly, a mixture is obtained;

[0055] (2) placing the molybdenum crucible 1 of the mixture described in step (1) in the vacuum crystal furnace 2;

[0056] (3) Vacuumize the vacuum crystal furnace 2, heat it to 1650°C and fill it with argon gas, then continue to heat up to 1950°C, after 8 hours of heat preservation, open the lifting mechanism 5, adjust the height of the crucible, so that the molybdenum crucible 1 is 2.0mm / The hourly speed gradually decreases, the melt 4 in the crucible 1 is solidified into a crystal 6 through the temperature gradient of 50°C / cm in the furnace cavity, and the vacuum crystal furnace lowers the furnace temperature to room temperature at a speed of 50°C / h to obtain the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com