Method for preparing quantum dot fluorescent microspheres through ultrasonic initiation

A technology of fluorescent microspheres and quantum dots, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., and can solve problems affecting fluorescence intensity, surface defects of quantum dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

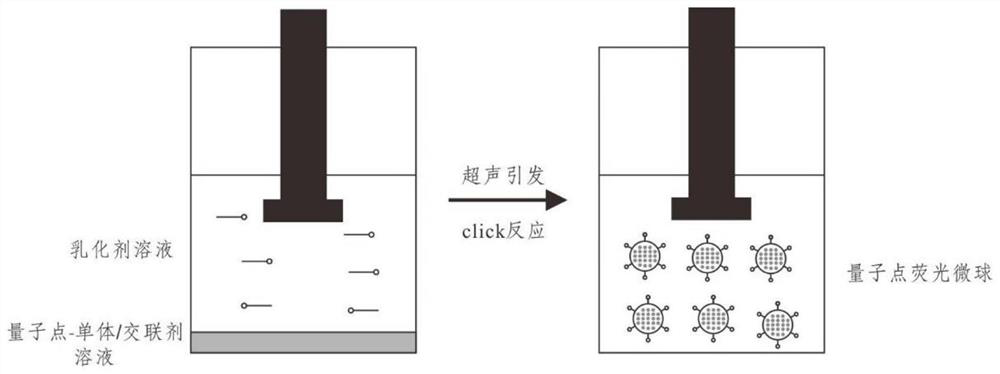

Method used

Image

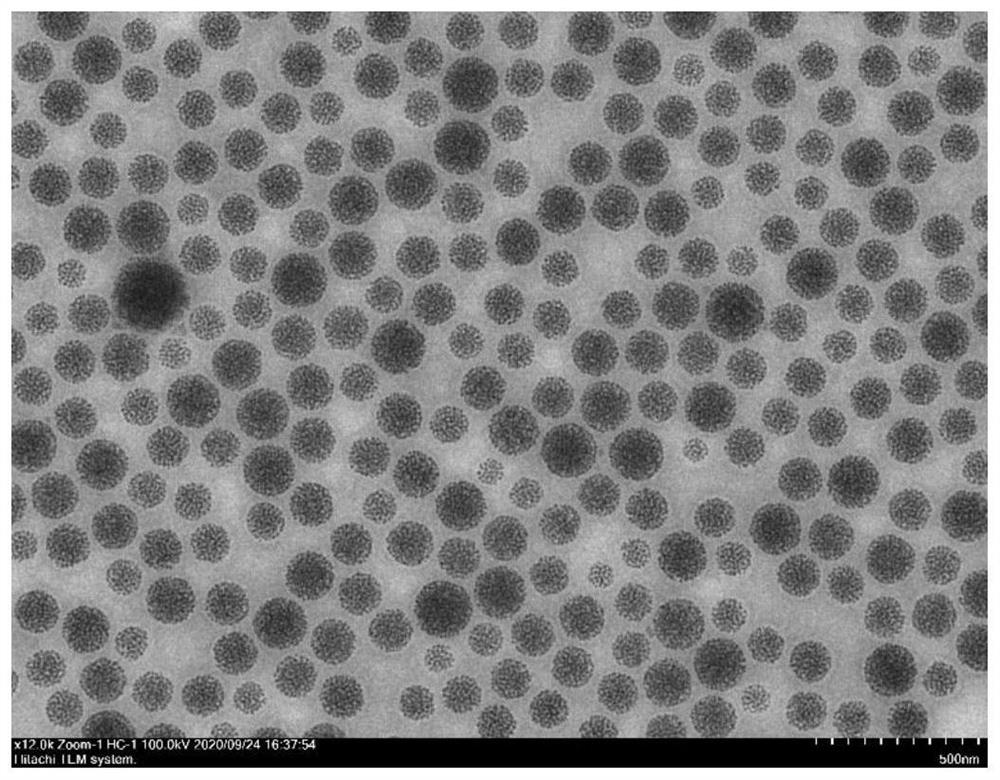

Examples

Embodiment 1

[0058] Weigh 0.6g of quantum dot powder, dissolve in 1g of styrene and 0.2g of divinylbenzene to form a quantum dot-monomer / crosslinking agent solution;

[0059] Pour the above solution into 100mL of 0.1g / L sodium dodecylsulfonate solution;

[0060] Start the ultrasonic reactor, set the temperature to 0°C, the power parameter to 50W, corresponding to a power density of 0.5kW / L, and ultrasonic emulsification for 15 minutes;

[0061] Set the temperature at 0°C, the power parameter is 400W, the corresponding power density is 4kW / L, and the reaction time is 4h;

[0062] Add 0.5mL glycidyl methacrylate dropwise and continue the reaction for 4h;

[0063] The temperature was returned to room temperature, glycine-sodium hydroxide solution (pH=12) was added dropwise, and the reaction was continued for 4h;

[0064] Stop ultrasonication, add dilute hydrochloric acid dropwise, adjust pH to 6, centrifuge at 6000rpm for 10min, disperse with ultrapure water ultrasonically, repeat 3 times t...

Embodiment 2

[0066] Weigh 0.6g quantum dot powder, dissolve in 0.25g styrene and 0.5g divinylbenzene to form quantum dot-monomer / crosslinking agent solution;

[0067] Pour the above solution into 100mL of 0.1g / L sodium dodecylsulfonate solution;

[0068] Start the ultrasonic reactor, set the temperature to 0°C, the power parameter to 300W, corresponding to a power density of 3kW / L, and ultrasonic emulsification for 15 minutes;

[0069] Set the temperature at 0°C, the power parameter is 400W, the corresponding power density is 4kW / L, and the reaction time is 4h;

[0070] Add 0.5mL glycidyl methacrylate dropwise and continue the reaction for 4h;

[0071] The temperature was returned to room temperature, glycine-sodium hydroxide solution (pH=12) was added dropwise, and the reaction was continued for 4h;

[0072] Stop ultrasonication, add dilute hydrochloric acid dropwise, adjust pH to 6, centrifuge at 6000rpm for 10min, disperse with ultrapure water ultrasonically, repeat 3 times to obtain ...

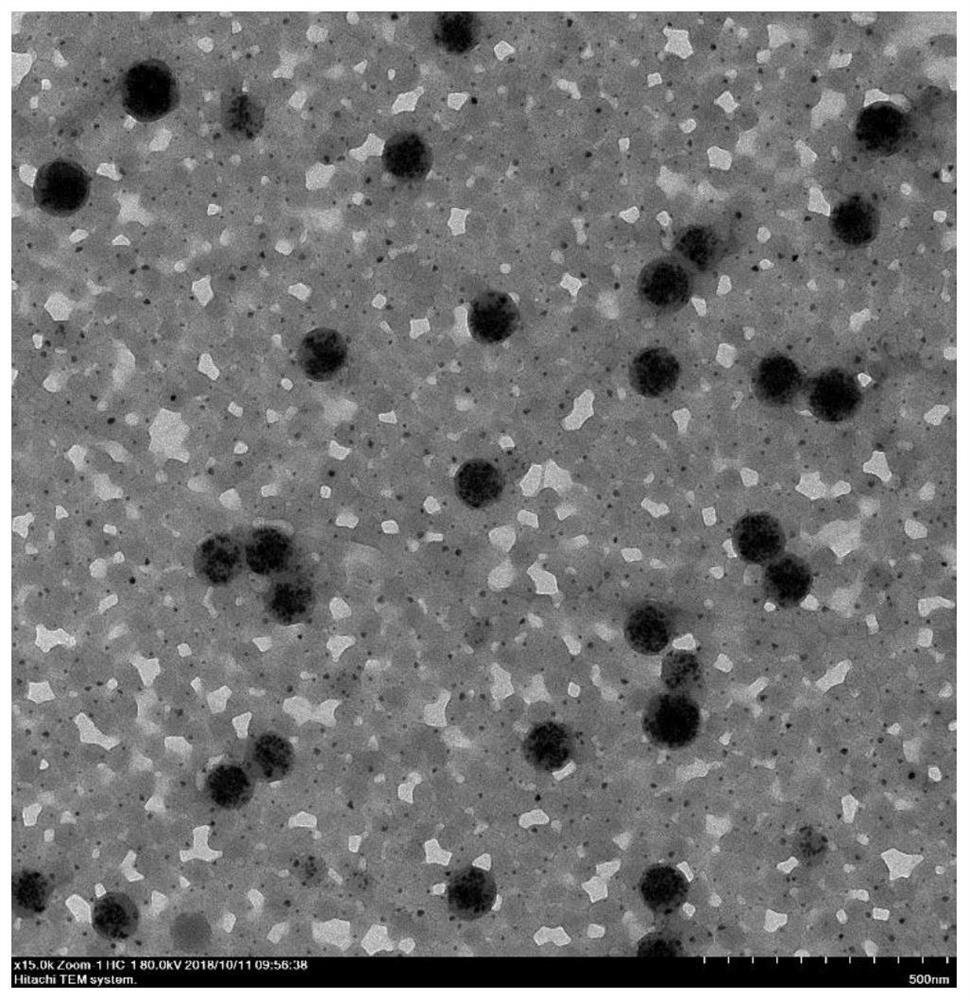

Embodiment 3

[0074] Weigh 0.6g quantum dot powder, dissolve in 0.25g styrene and 0.5g ethylene glycol diacrylate to form quantum dot-monomer / crosslinker solution;

[0075] Pour the above solution into 100mL of 0.1g / L sodium dodecylsulfonate solution;

[0076] Start the ultrasonic reactor, set the temperature to 0°C, the power parameter to 300W, corresponding to a power density of 3kW / L, and ultrasonic emulsification for 15 minutes;

[0077] Set the temperature to 0°C, the power parameter is 800W, the corresponding power density is 8kW / L, and the reaction time is 4h;

[0078] Add 0.5mL glycidyl methacrylate dropwise and continue the reaction for 4h;

[0079] The temperature was returned to room temperature, and aspartic acid-sodium hydroxide solution (pH=12) was added dropwise, and the reaction was continued for 4h;

[0080] Stop ultrasonication, add dilute hydrochloric acid dropwise, adjust pH to 6, centrifuge at 6000rpm for 10min, disperse with ultrapure water ultrasonically, repeat 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com