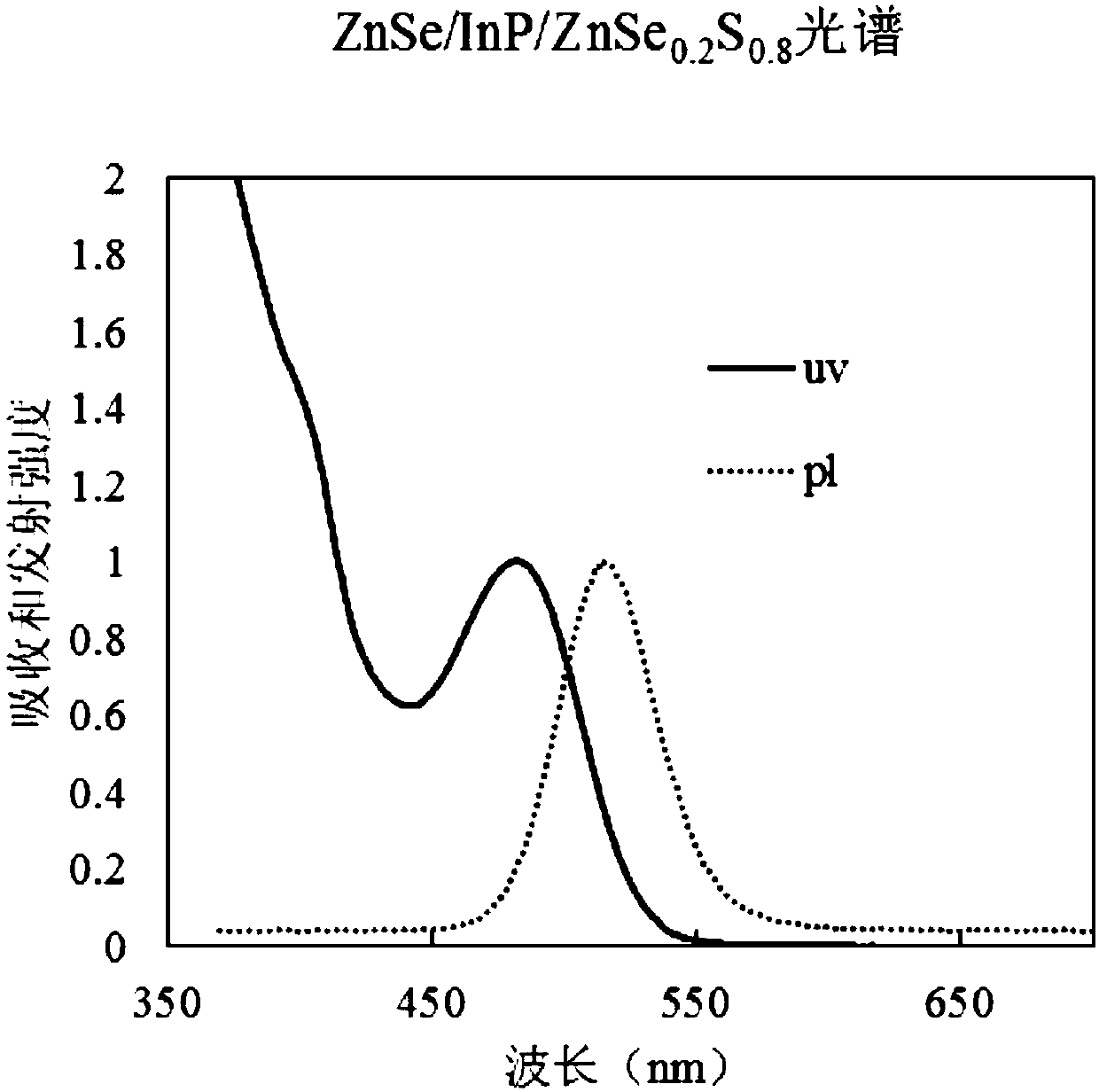

Znse/iii-v family/znsexs1-x or znse/iii-v family/znse/zns quantum dot and preparation method thereof

A III-V, quantum dot technology, used in chemical instruments and methods, nanotechnology for materials and surface science, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

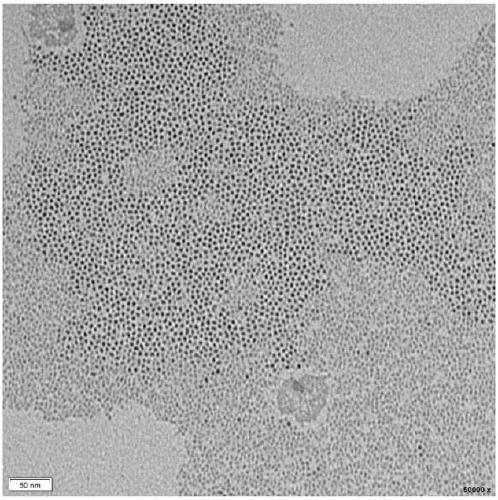

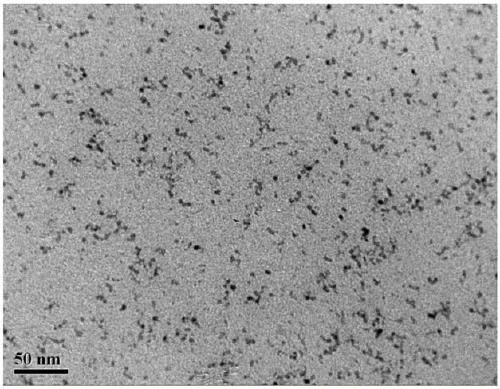

[0025] According to a typical embodiment of the present invention, there is provided a ZnSe / III-V group / ZnSe x S 1-x Or the preparation method of ZnSe / III-V group / ZnSe / ZnS quantum dots. The preparation method includes the following steps: the preparation method includes the following steps: S1, prepare a first mixed solution containing ZnSe nuclei and a non-coordinating solvent, and the temperature of the first mixed solution is ≤150°C; S2, add III to the first mixed solution Group element precursor solution to form the second mixed solution, heat up to 180-320°C, preferably 220-300°C, add group V element precursor solution to react, group III elements and group V elements are coated on the ZnSe core to form III- V group element shell layer, forming the third mixed liquid containing ZnSe / III-V group quantum dots; S3, coating ZnSe x S 1-x Or ZnSe / ZnS shell, get ZnSe / III-V group / ZnSe x S 1-x Or ZnSe / III-V group / ZnSe / ZnS quantum dots, where 0≤x≤1. The key of the present inv...

Embodiment approach

[0028] According to a typical implementation of the present invention, S3 specifically includes: adding a Zn precursor to the third mixed liquid containing ZnSe / III-V quantum dots, then heating to 180-320°C, adding Se and S mixed precursors solution, the synthesized ZnS is coated on the surface of the shell of III-V elements to obtain ZnSe / III-V / ZnSe x S 1-x Quantum dots; or add a Zn precursor to the third mixed solution containing ZnSe / III-V quantum dots, and then heat to 180-320°C, preferably 220-300°C, after adding the Se precursor solution and reacting completely, ZnSe is formed / III-V group / ZnSe, and then add the S precursor solution, and react for a certain period of time to obtain ZnSe / III-V group / ZnSe / ZnS quantum dots.

[0029] Preferably, the S precursor is one or more selected from the group consisting of sulfur-tributylphosphine, sulfur-trioctylphosphine, sulfur-octadecene and hexamethyldisilathane.

[0030] According to a typical embodiment of the present inventi...

Embodiment 1

[0038] Weigh 0.2mmol of zinc stearate and 6g of ODE into a three-necked bottle, exhaust in an inert gas for 10min, raise the temperature to 250°C, inject 0.1mmol of Se-ODE solution, and react for 20min to obtain ZnSe nuclei;

[0039] Cool down to 100°C and add 0.1mmol In(Ac) 3 Solid, warm up to 270°C and inject 0.1mmol TMSP and 0.1ml oleylamine, react for 10min;

[0040] Cool down to 100°C, add 0.5mmol zinc stearate, exhaust for 10 minutes, heat up to 270°C, inject TBP solution containing 0.06mmol Se and 0.24mmol S; cool down to 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com