Thermal field structure for growing large-sized silicon carbide monocrystal

A silicon carbide single crystal, large-scale technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficult growth, delay, expensive crystal, etc., to avoid crystal melting, reduce cracking, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

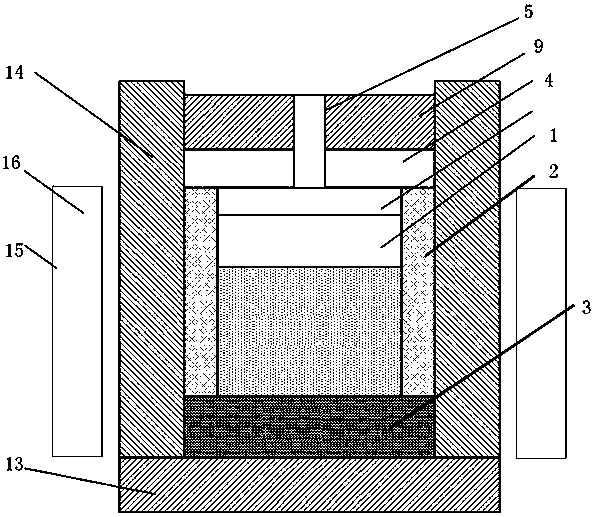

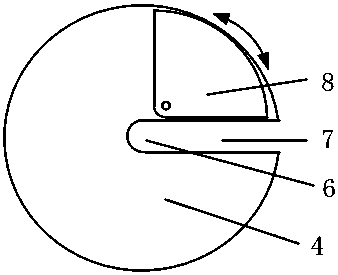

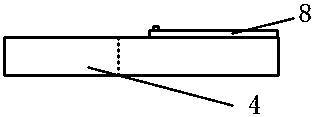

[0022] combine figure 1 The structure of this embodiment consists of a crucible 1, a crucible cover 4, a seed rod 5, an upper insulation layer structure 9, a lower insulation layer structure 13, a side insulation layer structure 14 and an induction coil structure 15. The crucible 1 is divided into two parts: a cylindrical bottomless structure 2 and a crucible holder 3. The cylindrical bottomless structure is placed on the upper part of the crucible holder, and the inside of the crucible is used to hold solid raw materials; the lower end of the seed crystal rod 5 is provided with a seed crystal tray 6 The structure is used to fix the seed crystal, and the seed rod can move axially through the control of the mechanical system; the crucible cover and the upper insulation structure are placed on the top of the crucible; in order to facilitate the installation of the seed rod, Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com