A kind of preparation method of trivalent rhodium acetate trimer

A technology of rhodium acetate trimer and glacial acetic acid, applied in the field of preparation of trivalent rhodium acetate trimer, can solve problems such as poor solubility, long synthesis time, easy dehydration, etc., and achieves increasing reaction rate, shortening production cycle, accelerating The effect of the precipitation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

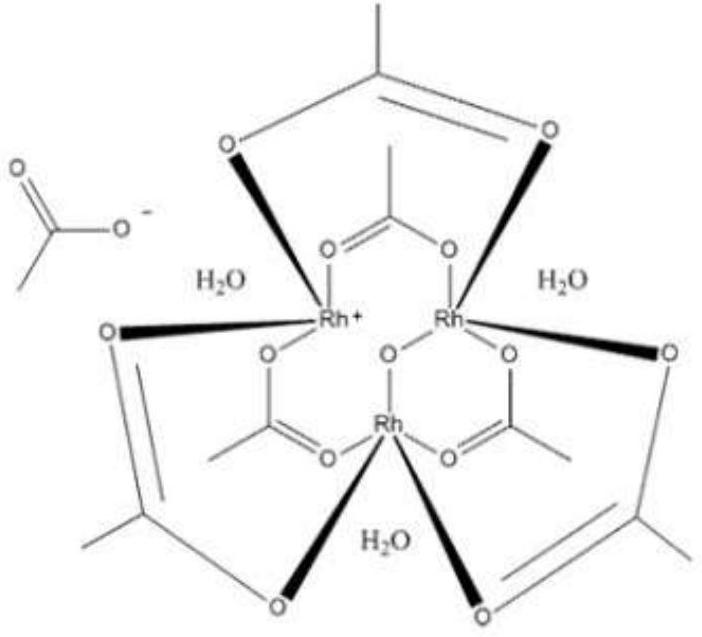

Image

Examples

preparation example Construction

[0043] A preparation method of trivalent rhodium acetate trimer, comprising the following steps:

[0044] (1) after mixing rhodium powder and potassium chloride, feed chlorine gas at a flow rate of 0.1~5L / min, and react at 500~800 ℃ for 1~5h;

[0045] (2) Dissolve the product obtained in step (1) in water, filter, add 10-40wt% potassium hydroxide solution to the filtrate to make the pH value between 7-10, react for 0.5-2h, after filtering and washing , to obtain rhodium hydroxide;

[0046] (3) in rhodium hydroxide, add water, 60~65wt% nitric acid and glacial acetic acid, the mass ratio of described rhodium hydroxide, water, nitric acid and glacial acetic acid is 1:2~30:0.5~3:1~5, The reaction is carried out at 30 to 90° C. for 0.5 to 3 hours, the solution is evaporated to dryness, and after nitrification is carried out with glacial acetic acid, the acid is carried out with water to obtain trivalent rhodium acetate trimer.

[0047] Optionally, in step (2), before adding potas...

Embodiment 1

[0053] A preparation method of trivalent rhodium acetate trimer, comprising the following steps:

[0054] (1) Mix 30g of rhodium powder and 100g of potassium chloride evenly, put it into a quartz boat, transfer it to a medium-temperature tube furnace at 600°C, pass chlorine gas at a flow rate of 1L / min, and react for 3h.

[0055] (2) dissolving the product obtained in step (1) in 0.5L water, filtering, adding 15wt% potassium hydroxide solution to the filtrate to adjust the pH to 8.0, reacting for 1h, filtering, and washing with 2L deionized water times to obtain Pure Rhodium Hydroxide. After testing, the yield of rhodium hydroxide prepared from potassium chlororhodate was 96.0%.

[0056] (3) get the rhodium hydroxide (0.100mol) that the rhodium content is 10.29g, add 100g deionized water to it, add 65% analytically pure nitric acid 29.08g and glacial acetic acid 28.00g simultaneously, 60 ℃ of stirring reflux 1h, filter , placed in an evaporating dish and evaporated to drynes...

Embodiment 2

[0058] A preparation method of trivalent rhodium acetate trimer, comprising the following steps:

[0059] (1) Mix 100g of rhodium powder and 200g of potassium chloride evenly, put it into a quartz boat, transfer it to a medium-temperature tube furnace at 650°C, pass chlorine gas at a flow rate of 4L / min, and react for 2h.

[0060] (2) dissolving the product obtained in step (1) in 1L water, filtering, adding 25wt% potassium hydroxide solution to the filtrate to adjust the pH to 9.0, reacting for 1.5h, filtering, and washing with 6L deionized water times to obtain Pure Rhodium Hydroxide. After testing, the yield of rhodium hydroxide prepared from potassium chlororhodate was 96.1%.

[0061] (3) get the rhodium hydroxide (0.488mol) that the rhodium content is 50.23g, add 400g deionized water to it, add 65% analytically pure nitric acid 150.00g and glacial acetic acid 300.00g simultaneously, 80 ℃ of stirring reflux 1.5h, Filtration, placed in an evaporating dish and evaporated t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com