Ultra-low emission device and method for sintering and pelletizing flue gas

An emission device and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high failure rate, low removal efficiency, waste of desulfurization and denitration reagents, process water gas and electric energy, etc., to prevent System equipment blockage, limestone saving, significant environmental and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

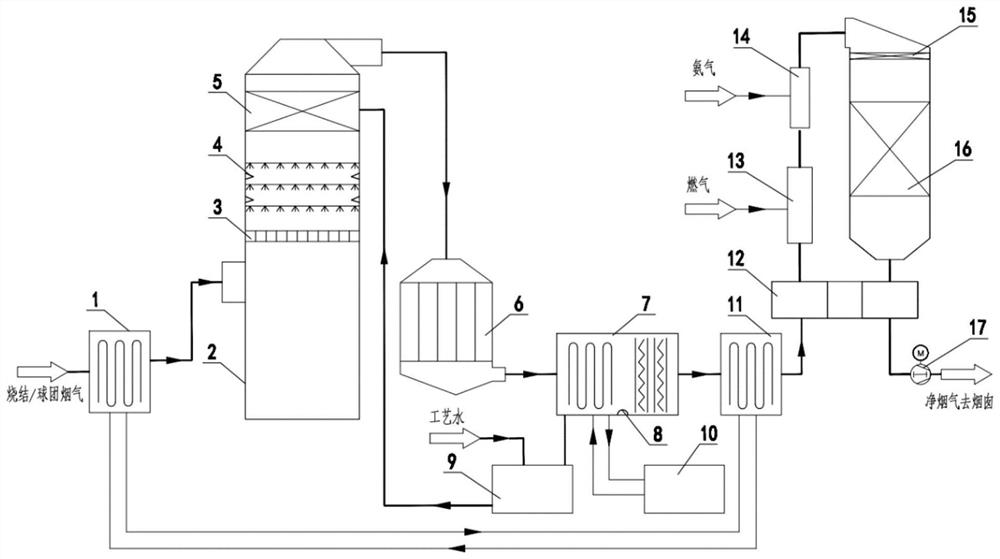

[0032] Attached below figure 1 The present invention is described in further detail with specific embodiment. The content not described in detail in this specification belongs to the prior art and structure known to those skilled in the art.

[0033] Such as figure 1 As shown, a sintering pellet flue gas ultra-low emission device of the present invention includes desulfurization and dust removal system equipment and denitrification reaction system equipment; the desulfurization and dust removal system equipment includes MGGH heat collector 1, desulfurization tower 2, wet electrostatic precipitator 6, Flue gas deacidification and mist removal system, MGGH heater 11; denitration reaction system equipment includes rotary heat exchanger 12, built-in burner 13, static mixer 14, denitration reactor 16, induced draft fan 17; flue gas passes through MGGH in turn Heat collector 1, desulfurization tower 2, wet electrostatic precipitator 6, acid and mist removal device for flue gas dea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com