Negative pole piece, electrochemical device comprising negative pole piece and electronic device

A technology of negative electrode sheet and negative electrode, which is applied in the field of electrochemistry and can solve problems such as short circuit, volume expansion, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]

[0054] In a dry argon atmosphere, mix dioxolane (DOL) and dimethyl ether (DME) at a volume ratio of DOL:DME=1:1 to obtain a mixed solvent, and then add lithium salt bistrifluoro Lithium methanesulfonimide (LiTFSI) was dissolved and mixed uniformly to obtain an electrolyte solution with a lithium salt concentration of 1 mol / L.

[0055]

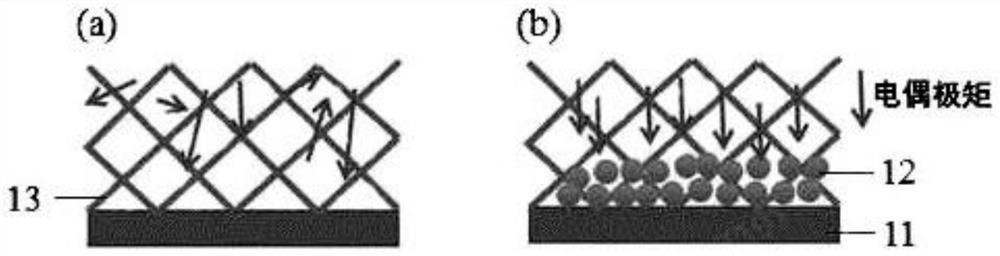

[0056](a)

[0057] Using electrospinning technology, a PVDF fiber membrane with a thickness of 10 μm was prepared using PVDF as a precursor, and the PVDF fiber membrane was placed in a vacuum drying oven at 80°C for 12 hours to obtain a negative electrode skeleton with a thickness of 10 μm. Among them, the porosity of the negative electrode skeleton is 85%.

[0058] (b)

[0059] Electrochemical lithium supplementation is used for pre-supplementation of lithium, and the lithium source is a lithium sheet with a thickness of 0.05mm. Choose a 15μm PE separator, place the negative electrode skeleton and lithium metal on both sides ...

Embodiment 2

[0070] In Example 2, Example 3, Example 4, Example 5, Example 6, Example 7, Example 8 and Example 9, , , , and are the same as in Example 1, and the changes of relevant preparation parameters are shown in Table 1:

[0071] Table 1

[0072]

Embodiment 10

[0074] (a)

[0075] Disperse the PVDF powder in NMP, disperse the PVDF evenly by stirring to obtain a slurry with a solid content of 12%, and use a scraper to coat the slurry on one surface (first surface) of a lithium metal negative electrode with a thickness of 30 μm to form The coating layer with a thickness of 100 μm was dried in a vacuum oven at 80° C. for 12 hours to obtain a negative electrode skeleton with a thickness of 100 μm. Among them, the average particle diameter of the PVDF powder is 10 μm, and the porosity of the negative electrode skeleton is 70%.

[0076] (b)

[0077] The negative electrode skeleton prepared above is placed in a parallel electric field for air polarization. The polarization electric field is 50kV / mm, and the polarization time is 30min. (The second surface) faces the negative pressure side. Among them, the room temperature coercive field strength Ec of PVDF is 50kV / mm.

[0078] (c)

[0079] In a dry argon atmosphere, the second surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com