Preparation method of graphene/silicon nanosheet/carbon nanotube composite material

A technology of silicon nanosheets and carbon nanotubes, which is applied in the field of energy materials, can solve the problems that silicon electrodes are prone to fragmentation and pulverization, and affect the electrochemical performance of electrode materials, so as to inhibit the formation of unstable SEI films, raw materials Inexpensive and highly controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 of the present invention discloses a preparation method of a graphene / silicon nanosheet / carbon nanotube composite material, and the adopted technical scheme is as follows:

[0035] A graphene / silicon nanosheet / carbon nanotube composite material, characterized in that the mass ratio of the silicon nanosheet, carbon nanotube and graphene is 1:0.5:0.5.

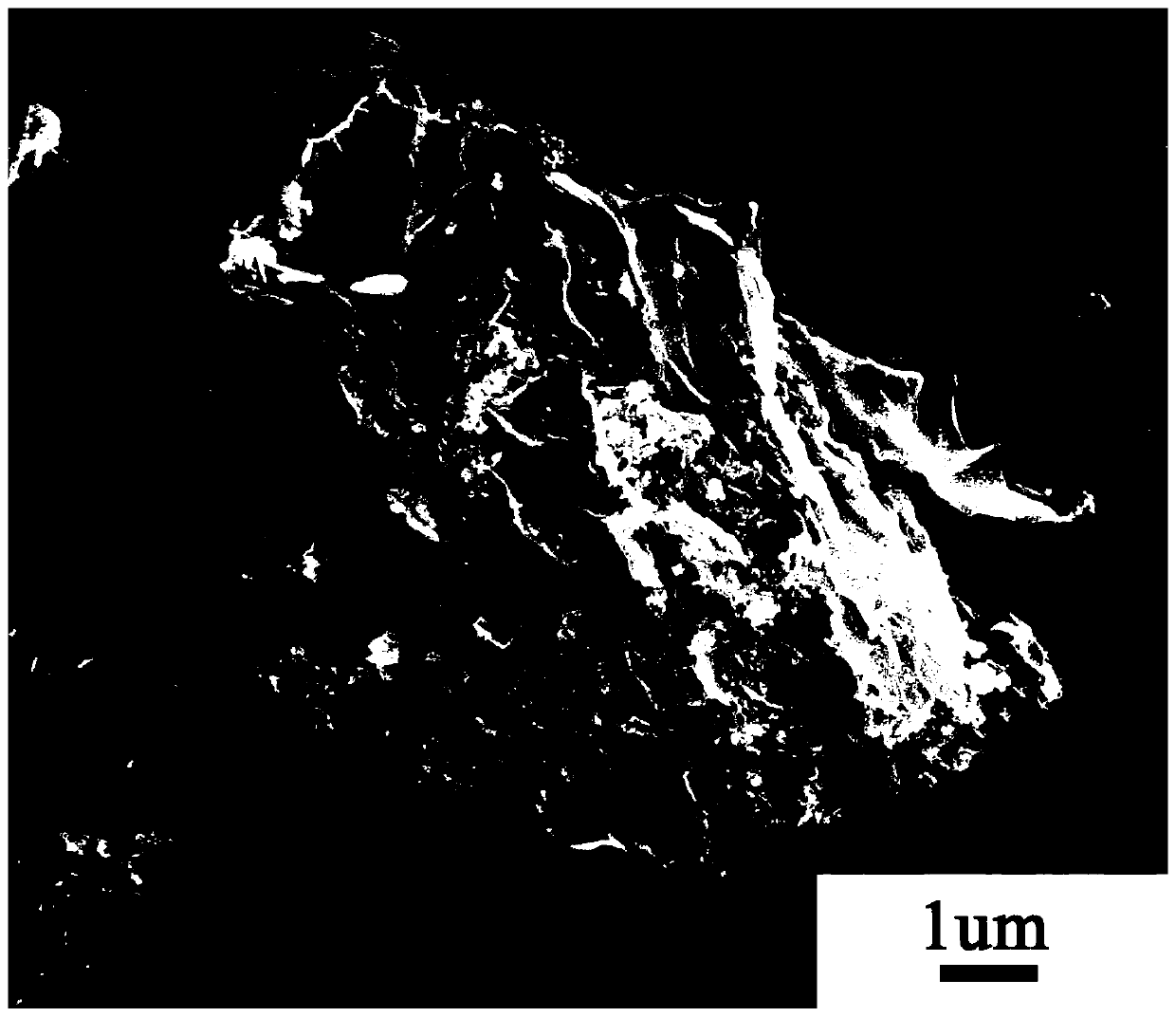

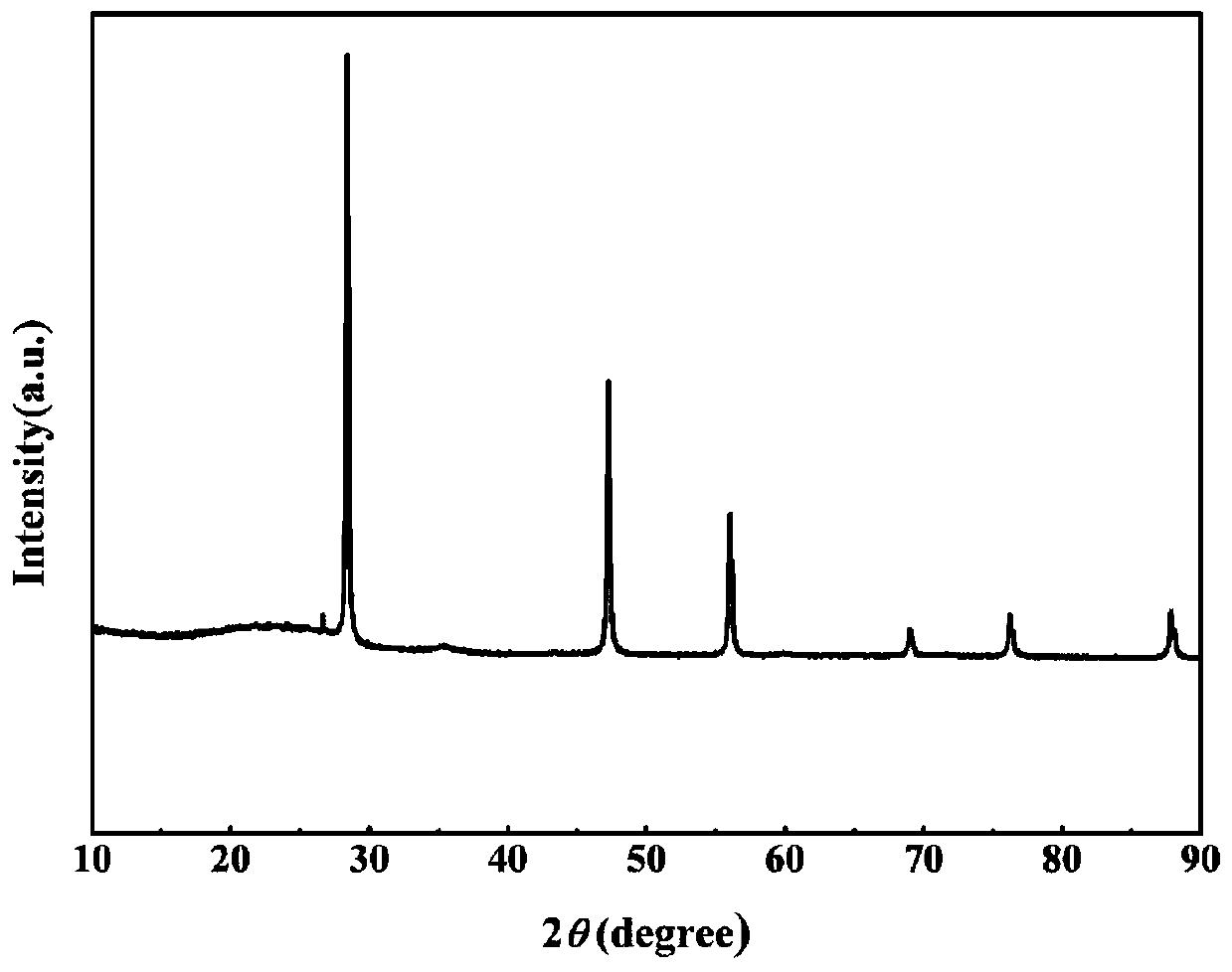

[0036] S1, prepare a silicon nanosheet solution: weigh montmorillonite, magnesium powder, and NaCl in a mass ratio of 1:1:2 to a total of 4 g, mix evenly, and keep at 650 °C for 5 h in an Ar atmosphere for magnesium thermal reduction, and then reduce to room temperature Then, the obtained solid mixture was soaked in a HCl solution with a concentration of 2M and a HF solution with a volume concentration of 5% for more than 2h, to remove unreacted silicon oxide, magnesium powder and Mg. 2 Si and other impurities, washed with distilled water for 5 times, and vacuum-dried at 80 °C for 10 h to obtain silicon nanosh...

Embodiment 2

[0046] Embodiment 2 of the present invention discloses a preparation method of a graphene / silicon nanosheet / carbon nanotube composite material, and the adopted technical scheme is as follows:

[0047] A graphene / silicon nanosheet / carbon nanotube composite material, characterized in that the mass ratio of the silicon nanosheet, carbon nanotube and graphene is 1:1.5:0.5.

[0048] S1, prepare a silicon nanosheet solution: weigh 8 g of montmorillonite, magnesium powder, and NaCl in a mass ratio of 1:1:2, mix evenly, hold at 650 °C for 5 h in an Ar atmosphere for magnesium thermal reduction, and then reduce to room temperature Then, the obtained solid mixture was soaked in HCl solution with a concentration of 2M and a HF solution with a volume concentration of 5% for more than 2 hours to remove impurities such as unreacted silicon oxide, magnesium powder and Mg2Si, and washed with distilled water for 5 times. , 80 ℃ of vacuum drying for 10h to obtain silicon nanosheet material. We...

Embodiment 3

[0055] Embodiment 3 of the present invention discloses a preparation method of a graphene / silicon nanosheet / carbon nanotube composite material, and the adopted technical scheme is as follows:

[0056] A graphene / silicon nanosheet / carbon nanotube composite material, characterized in that the mass ratio of the silicon nanosheet, carbon nanotube and graphene is 1:1:1.

[0057] S1, prepare a silicon nanosheet solution: weigh 4 g of montmorillonite, magnesium powder, and NaCl in a mass ratio of 1:1:1, mix evenly, and keep at 650 °C for 5 h in an Ar atmosphere for magnesium thermal reduction, and then reduce to room temperature Then, the obtained solid mixture was soaked in a HCl solution with a concentration of 2M and a HF solution with a volume concentration of 5% for more than 2h, to remove unreacted silicon oxide, magnesium powder and Mg. 2 Si and other impurities, washed with distilled water for 5 times, and vacuum-dried at 80 °C for 10 h to obtain silicon nanosheet materials. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com