Tower connecting node, heat treatment method thereof and lightning protection tower for power transmission and transformation

A heat treatment method and technology for connecting nodes, applied in heat treatment furnaces, heat treatment equipment, configuration of grounding wires, etc., can solve problems such as impact performance drop, strength or hardness drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Use low-carbon and low-phosphorus stamping plate material as the melting raw material, then add ferroniobium, rare earth refining agent and diffusion deoxidizer, then add aluminum ingot for deoxidation, then blow in argon gas to purify molten steel, remove impurities, and cast to obtain G24Mn6 material Castings.

[0048] The inventor detected the cast parts, the main components are as follows: C: 0.22%, Si: 0.30%, Mn: 1.68%, Cr: 0.15%, Mo: 0.10%, Ni: 0.35%, Nb: 0.015%, P: 0.005 %, S: 0.002%, V: 0.02%, Cu: 0.10%.

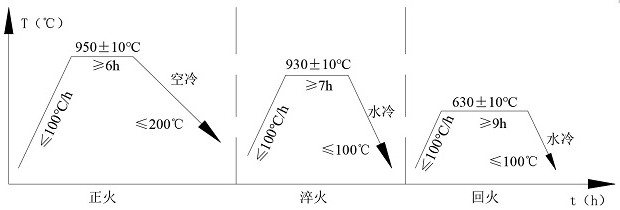

[0049] Carry out preheating treatment on the castings, raise the temperature to 950°C, the heating rate is 65°C / h, soak for 6 hours, then air cool to below 200°C and then air cool to below 200°C; then quenching treatment, the preheated castings Raise the temperature to 930°C with a heating rate of 85°C / h, soak for 7 hours, then water-cool to below 100°C; then temper, raise the temperature of the quenched piece to 630°C with a heating rate of 70°C / h, hold the ...

Embodiment 2

[0053] Use low-carbon and low-phosphorus stamping plate material as the melting raw material, then add ferroniobium, rare earth refining agent and diffusion deoxidizer, then add aluminum ingot for deoxidation, then blow in argon gas to purify molten steel, remove impurities, and cast to obtain G24Mn6 material Castings.

[0054] The inventor detected the cast parts, the main components are as follows: C: 0.25%, Si: 0.50%, Mn: 1.75%, Cr: 0.15-0.25%, Mo: 0.15%, Ni: 0.40%, Nb: 0.015-0.025% , P: 0.005%, S: 0.002%, V: 0.02%, Cu: 0.10%.

[0055] Carry out preheating treatment on the casting, raise the temperature to 950°C, the heating rate is 100°C / h, soak for 7 hours, and then air cool to below 200°C; then quenching treatment, raise the temperature of the casting after preheating to 930°C, and heat up The speed is 100°C / h, soaking for 8h, then water cooling to below 100°C; then tempering treatment, the quenched piece is heated to 630°C, the heating rate is 100°C / h, isothermal for 1...

Embodiment 3

[0059] Use low-carbon and low-phosphorus stamping plate material as the melting raw material, then add ferroniobium, rare earth refining agent and diffusion deoxidizer, then add aluminum ingot for deoxidation, then blow in argon gas to purify molten steel, remove impurities, and cast to obtain G24Mn6 material Castings.

[0060] The inventor detected the cast parts, the main components are as follows: C: 0.24%, Si: 0.40%, Mn: 1.70%, Cr: 0.20%, Mo: 0.13%, Ni: 0.38%, Nb: 0.020%, P: 0.005 %, S: 0.002%, V: 0.02%, Cu: 0.10%.

[0061] Carry out preheating treatment on the casting, raise the temperature to 950°C, the heating rate is 80°C / h, soak for 7 hours, and then air cool to below 200°C; then quenching treatment, raise the temperature of the casting after preheating to 930°C, and heat up The speed is 90°C / h, soaking for 8h, then water cooling to below 100°C; then tempering, the quenched piece is heated to 630°C, the heating rate is 85°C / h, isothermal for 10h, and then water cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com