Preparation method of high-osteoinductivity alpha-tricalcium phosphate nano-powder for 3D printing

A technology of tricalcium phosphate nanometer and 3D printing, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the instability of α-TCP and restrict the market application of α-TCP/3D printing technology and technology development, poor osteoinductive performance of α-TCP, etc., to achieve excellent osteoinductive performance, broad prospects for biomedical applications, and reduced energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

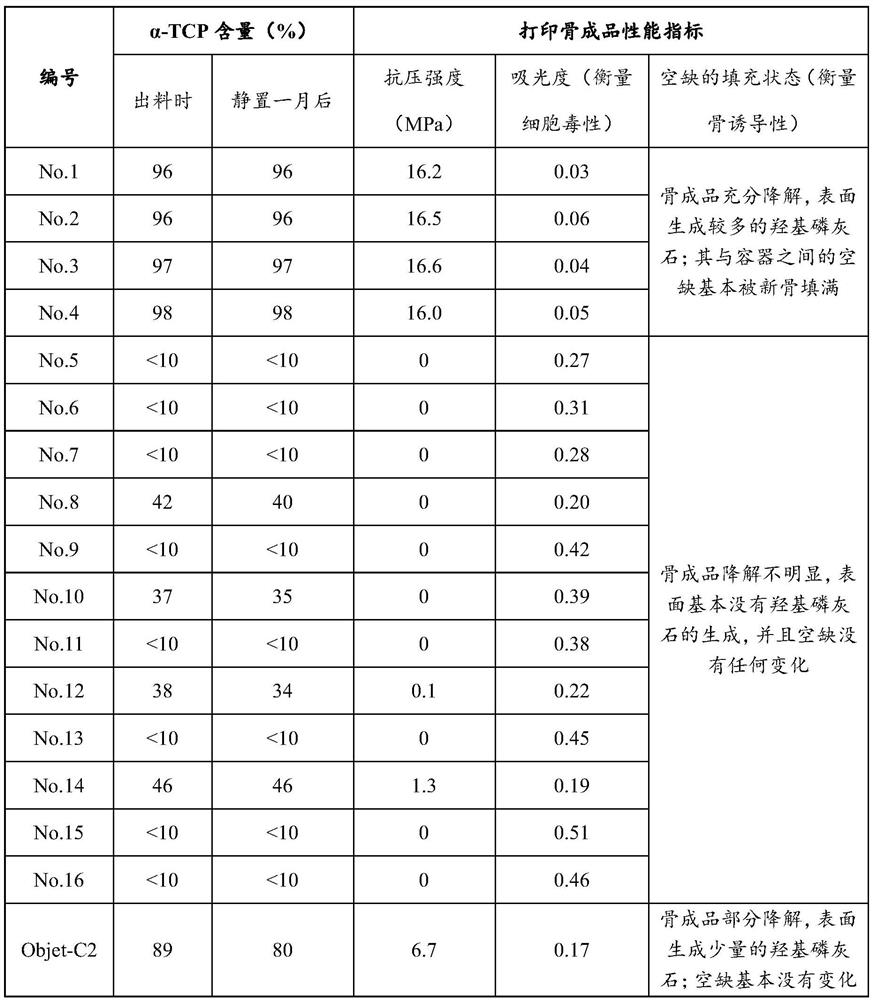

Examples

Embodiment 1

[0047] The highly osteoinductive α-tricalcium phosphate nanopowder for 3D printing described in Example 1 and its preparation method are prepared from the following raw material components in parts by mass according to the following steps:

[0048] (1) First, 1 part of Ce(NO 3 ) 3 , 0.1 part LiCl, 20 parts Ca(NO 3 ) 2 , 5 parts of sodium chloride and 500 parts of pure water were added to the hydrothermal reaction kettle and fully stirred evenly, then slowly dripped into 20 water glass with a modulus of 3.1, and the dropping time was controlled to be 15 minutes; Heat it to 150°C and keep it warm for 30 minutes; then stop the reaction and cool down to room temperature to discharge, first filter and wash the reaction liquid fully, and then roast the filter cake at 200°C for 10 minutes to prepare negatively charged phyllosilicate 1#.

[0049] (2) Then first add 0.1 part of negatively charged phyllosilicate 1# and 1000 parts of pure water prepared in the above steps (1) to the h...

Embodiment 2

[0051] The highly osteoinductive α-tricalcium phosphate nanopowder for 3D printing described in Example 2 and its preparation method are prepared from the following raw material components in parts by mass according to the following steps:

[0052] (1) First, 2.5 parts of Ce 2 (SO 4 ) 3 , 2.5 parts Dy(NO 3 ) 3 , 0.25 Li 2 SO 4 , 0.25 parts of LiOH, 25 parts of Ca(NO 3 ) 2 , 25 parts of CaCl 2 , 5 parts of sodium chloride and 500 parts of pure water were added to the hydrothermal reaction kettle and fully stirred evenly, then slowly dripped into 50 parts of water glass with a modulus of 3.4, and the dropping time was controlled to be 60 minutes; Raise the temperature to 200°C and keep it warm for 60 minutes; then stop the reaction and cool down to room temperature to discharge, first fully filter and wash the reaction solution, and then roast the filter cake at 300°C for 30 minutes to obtain negatively charged layered silicate 2# .

[0053] (2) then first add 0.5 part...

Embodiment 3

[0055] The highly osteoinductive α-tricalcium phosphate nanopowder for 3D printing described in Example 3 and its preparation method are prepared from the following raw material components in parts by mass according to the following steps:

[0056] (1) First, 1 part of CeCl 3 , 1 Dy 2 (SO 4 ) 3 , 1 part of DyCl 3 , 0.1 part LiCl, 0.1 part Li 2 SO 4 , 0.1 part of LiOH, 30 parts of Ca(NO 3 ) 2 , 30 parts of CaCl 2 , 5 parts of sodium chloride and 500 parts of pure water were added to the hydrothermal reaction kettle and fully stirred evenly, then slowly dripped into 30 parts of water glass with a modulus of 3.2, and the dropping time was controlled to be 30min; Raise the temperature to 160°C and keep it warm for 30 minutes; then stop the reaction and cool down to room temperature to discharge, first fully filter and wash the reaction solution, and then roast the filter cake at 250°C for 15 minutes to obtain negatively charged layered silicate 3# .

[0057] (2) then fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com