Triblock copolymer tough resin latex and preparation method thereof

A technology of block copolymers and copolymers, applied in the field of triblock copolymer tough resin latex and preparation, can solve the problems of difficult multi-performance and high-performance requirements, achieve narrow molecular weight distribution, high monomer conversion rate, molecular weight Growth controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

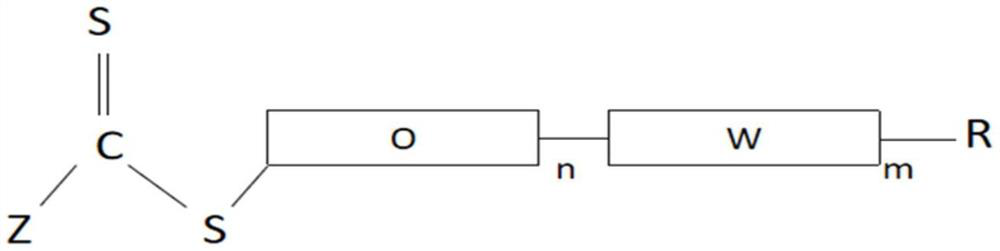

Method used

Image

Examples

Embodiment 1

[0024] 1.2 g of amphiphilic macromolecular reversible addition chain scission chain transfer reagent (1) was dissolved in 60 parts by weight of water, 9 g of styrene and 9 g of methyl methacrylate were added to the reactor as the first monomer, stirred and mixed, Nitrogen was blown until the air was completely replaced, and the temperature was raised to 80° C., then 0.03 g of a water-soluble initiator was added to initiate polymerization for 80 minutes, and then an aqueous solution containing 0.19 g of sodium hydroxide was added. After 1 hour, add 4g of ethyl acrylate as the second-stage monomer, polymerize for 0.6 hours, then add 9g of styrene and 9g of methyl methacrylate as the third-stage monomer, and polymerize for 2 hours to obtain a tri-block copolymer latex .

Embodiment 2

[0026] 1.2 g of amphiphilic macromolecular reversible addition chain scission chain transfer reagent (1) was dissolved in 60 parts by weight of water, 9 g of styrene and 9 g of methyl methacrylate were added to the reactor as the first monomer, stirred and mixed, Nitrogen was blown until the air was completely replaced, and the temperature was raised to 80° C., then 0.03 g of a water-soluble initiator was added to initiate polymerization for 80 minutes, and then an aqueous solution containing 0.19 g of sodium hydroxide was added. After 1 hour, add 8.8g of ethyl acrylate as the second-stage monomer, polymerize for 1 hour, then add 9g of styrene and 9g of methyl methacrylate as the third-stage monomer, and polymerize for 2 hours to obtain a tri-block copolymer latex.

Embodiment 3

[0028] 1.2 g of amphiphilic macromolecular reversible addition chain scission chain transfer reagent (1) was dissolved in 110 parts by weight of water, 4.5 g of styrene and 13.5 g of methyl methacrylate were added to the reactor as the first monomer, and stirred Mix, pass nitrogen until the air is completely replaced, heat up to 80° C., then add 0.03 g of water-soluble initiator, initiate polymerization for 80 minutes, then add an aqueous solution containing 0.19 g of sodium hydroxide. After 1 hour, add 15g of ethyl acrylate as the second-stage monomer, polymerize for 1.2 hours, then add 4.5g of styrene and 13.5g of methyl methacrylate as the third-stage monomer, and polymerize for 2 hours to obtain a tri-block copolymer object latex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com