Ring groove machining method of high-temperature alloy casing

A technology of superalloy and processing method, applied in the field of superalloy casing, can solve the problems of large wear of processing tools and long processing time, and achieve the effects of improving tool life, improving processing efficiency and reducing processing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Install the special fixture on the five-axis CNC machine tool, set the positioning center of the aligning fixture as the G54 XY zero point, set the angular direction of the aligning fixture as the positive direction of the X axis, install the superalloy casing on the fixture positioning circle, and fix it tightly. In the center of G54, the outer circle runout of the parts must be within 0.01mm, and the upper surface of the high-temperature alloy casing should be set as the Z zero point of G54;

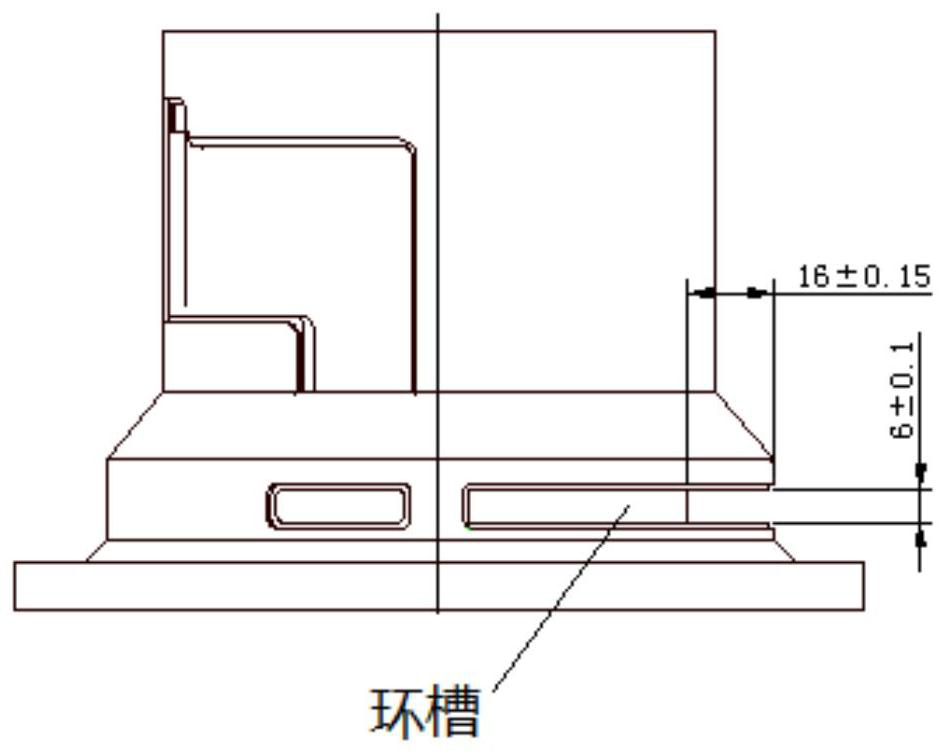

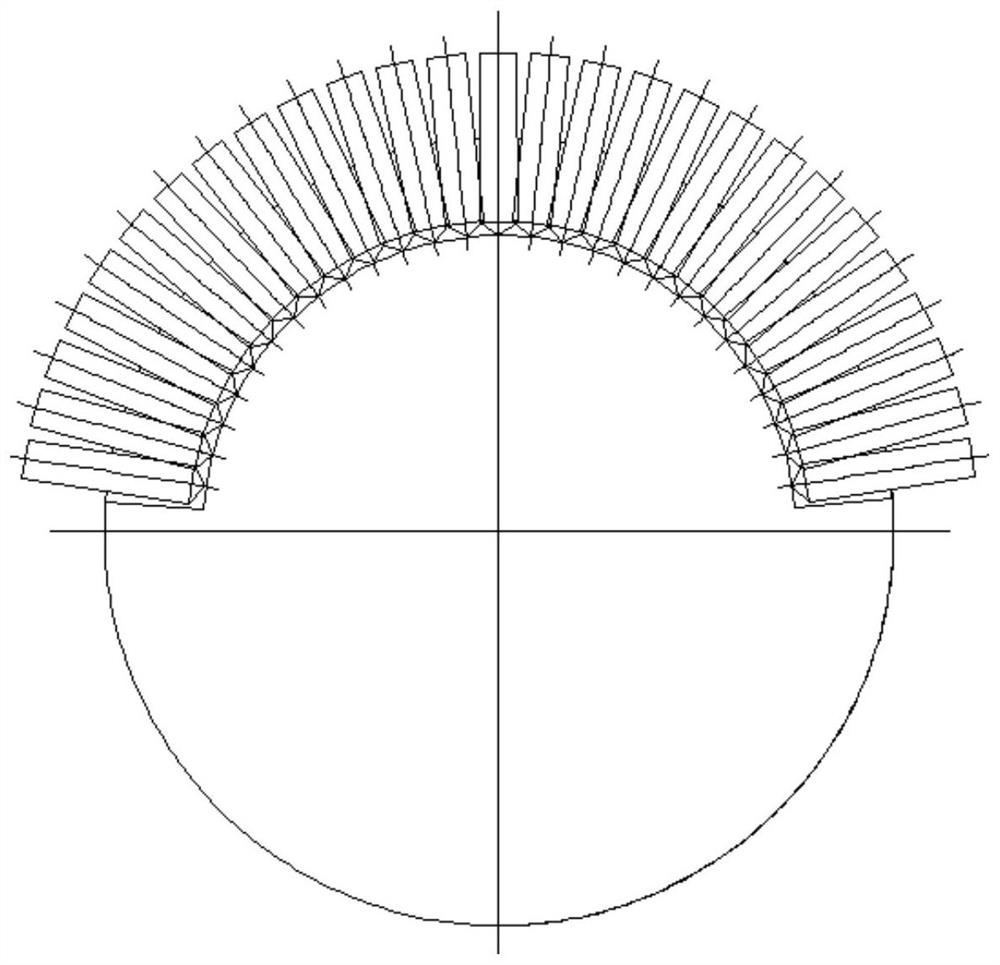

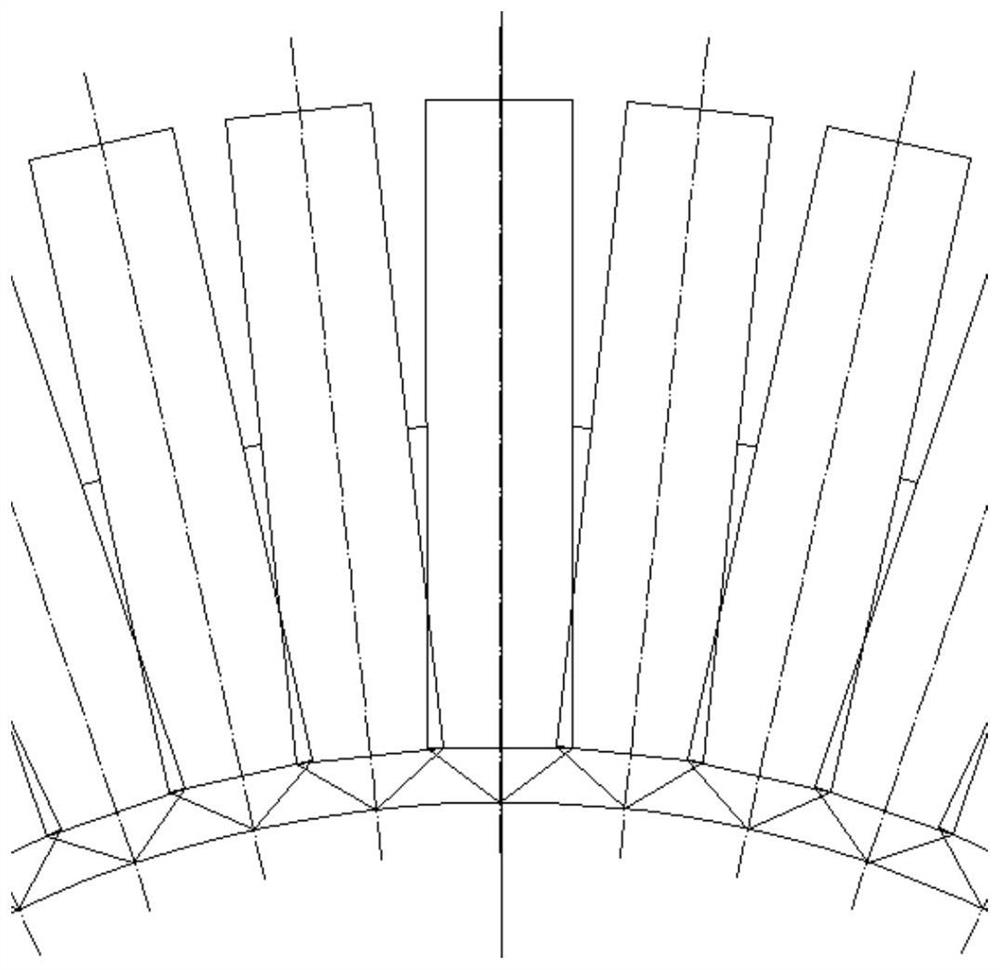

[0053] For rough machining, the processing area of the ring groove is determined on the high-temperature alloy casing according to the design requirements. The groove width of the processed ring groove is 6mm, the depth is 16mm, and the ring angle is 170°. A Φ5.5 drill bit is installed on the CNC machine tool. The Φ5.5 drill bit drills the processing area vertically, and drills a row of drilling holes along the circumferential direction of the ring groove on the 170° ring groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com