Melting sample preparation method for measuring silicon-aluminum-calcium-iron alloy through X-ray fluorescence spectrometry

A technology of fluorescence spectroscopy and fusion sample preparation, which is applied in the field of determination of silicon-aluminum-calcium-iron alloys, can solve the problems of long time consumption and low inspection efficiency, achieve the effects of reducing waste samples, strong operability, and improving personnel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

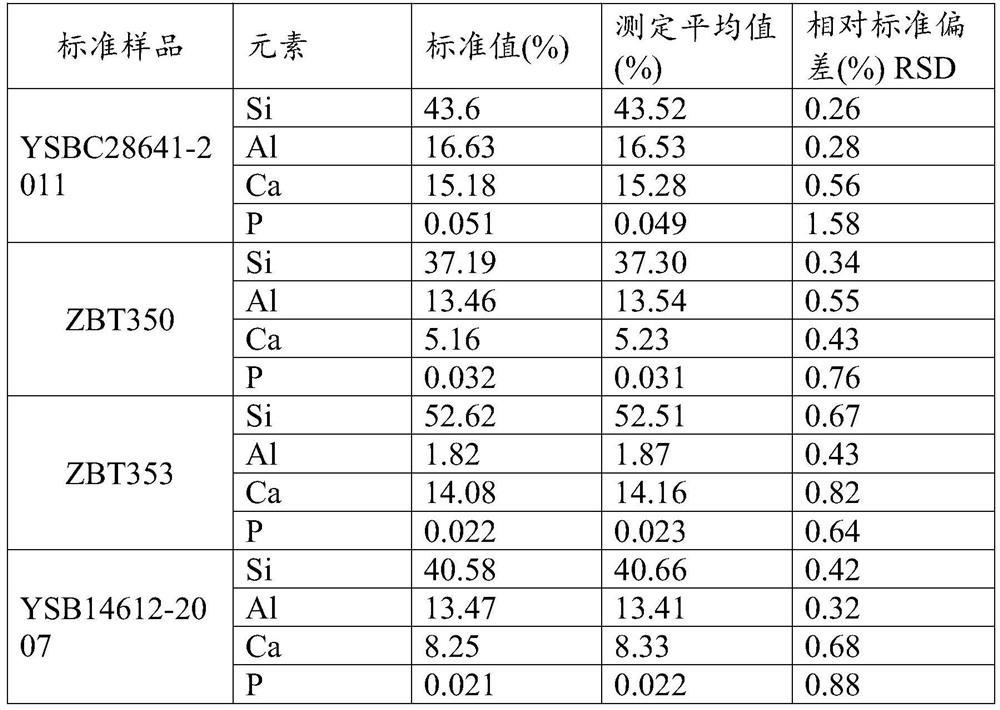

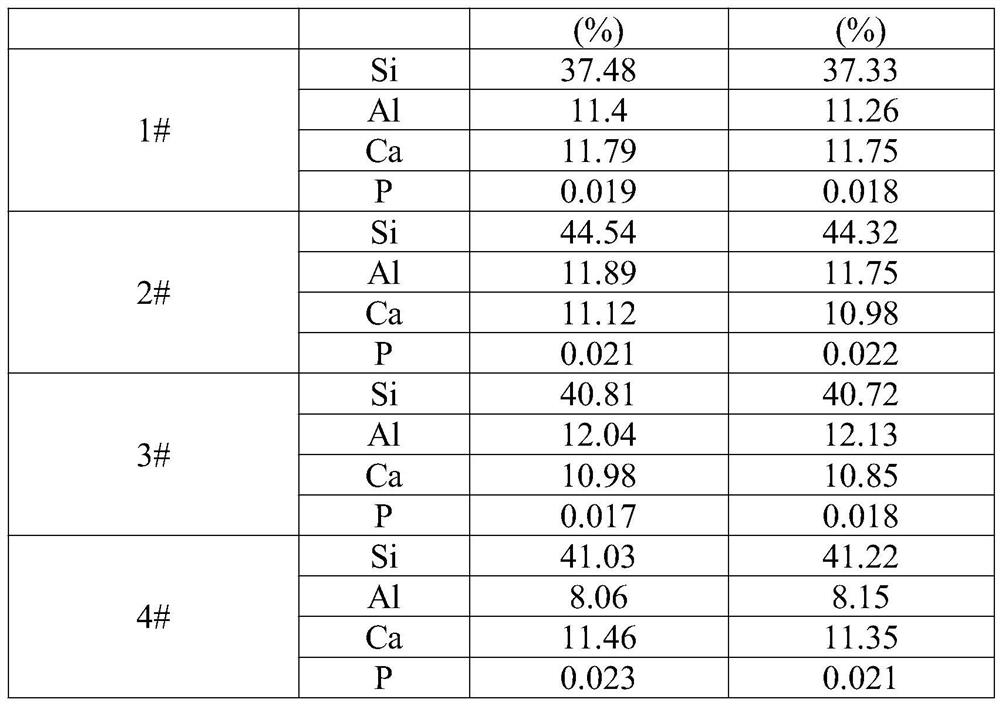

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions in the present application, the following clearly and completely describes the technical solutions in the embodiments of the present application.

[0023] The core of this application is to provide a melting sample preparation method for X-ray fluorescence spectrometry determination of silicon-aluminum-calcium-iron alloy, which can solve the problems of long time-consuming, low inspection efficiency and cost in the traditional detection method of silicon-aluminum-calcium-iron alloy in the prior art .

[0024] A kind of fusion sample preparation method that is used for X-ray fluorescence spectrometry to measure silicon-aluminum-calcium-iron alloy comprises the following steps:

[0025] The first step is to take a platinum-gold crucible, weigh 5g of anhydrous lithium tetraborate into the platinum-gold crucible, place the platinum-gold crucible filled with anhydrous lithium tetraborate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com