Resin catalyst as well as preparation method and application thereof

A technology of catalyst and resin, which is applied in the field of resin catalyst and its preparation, can solve problems such as poor conversion rate, achieve the effect of reducing bead collision, improving uniformity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

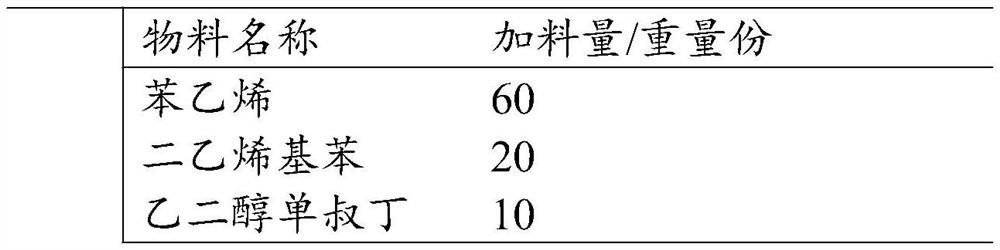

Embodiment 1

[0033] Catalyst A:

[0034] polymerization

[0035] Styrene, divinylbenzene, porogen, and initiator are weighed into the mixing tank, stirred for 0.5h, and the material and liquid are mixed evenly to become the oil phase. Add water, main dispersant, auxiliary dispersant and water-phase polymerization inhibitor into the polymerization kettle, stir and heat up to 40°C to make it completely dissolve, then add mixed monomer, adjust the stirring speed to 130 rpm according to the dispersion of the monomer, And slowly raise the temperature to 80°C for polymerization. After reacting for 8 hours, cool and discharge the polymer, wash the polymer three times with hot water and cold water respectively, and separate the white balls.

[0036] extract

[0037] Put the white ball into the extraction kettle, add excess toluene to the distillation kettle and heat it to evaporate the solvent in the kettle, and flow into the extraction kettle after condensation, the solvent will partially diss...

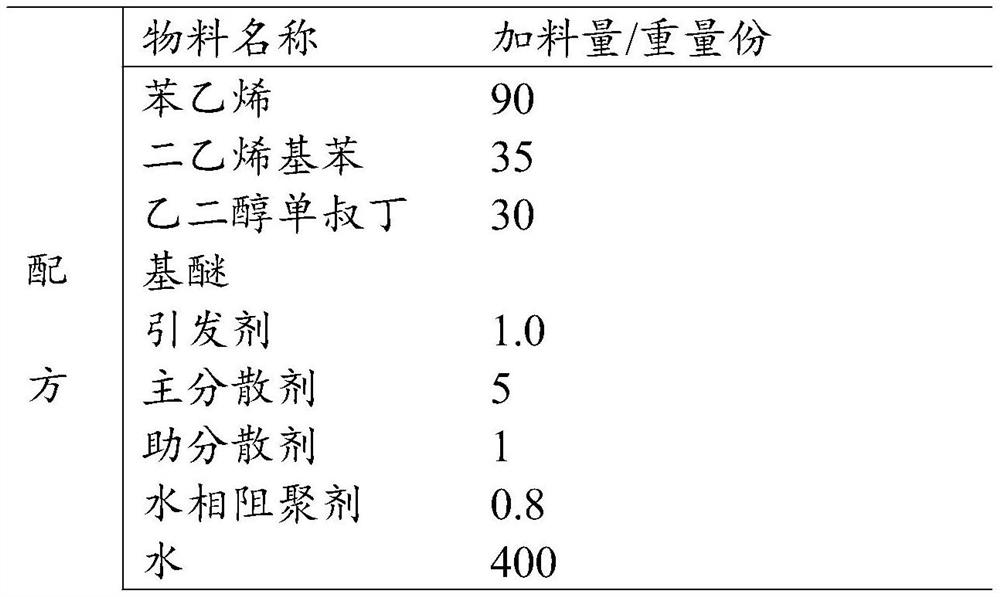

Embodiment 2

[0046] Catalyst B:

[0047] polymerization

[0048] Styrene, divinylbenzene, porogen, and initiator are weighed into the mixing tank, and stirred for 4.0 hours, so that the material and liquid are mixed evenly and become the oil phase. Add water, main dispersant, auxiliary dispersant and water-phase polymerization inhibitor into the polymerization kettle, stir and heat up to 50°C to make it completely dissolve, then add mixed monomer, adjust the stirring speed to 150 rpm according to the dispersion of the monomer, And slowly raise the temperature to 80°C for polymerization. After reacting for 18 hours, cool and discharge the polymer, wash the polymer three times with hot water and cold water respectively, and separate the white balls.

[0049] extract

[0050]Put the white ball into the extraction kettle, add excess toluene to the distillation kettle and heat it to evaporate the solvent in the kettle, and flow into the extraction kettle after condensation, the solvent will ...

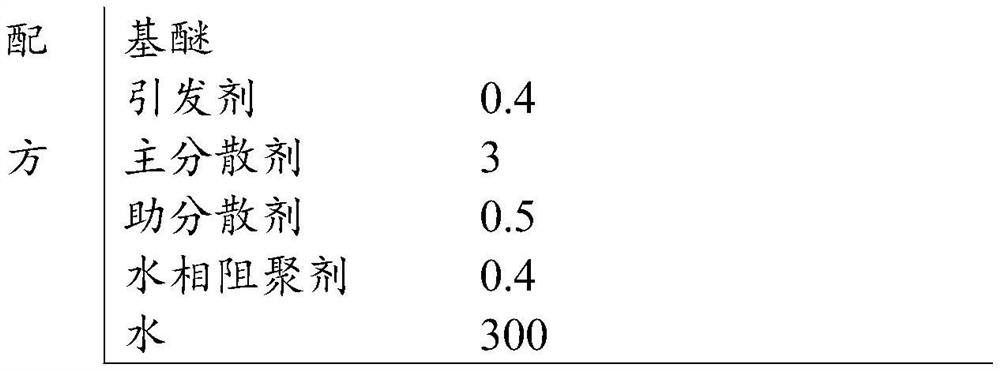

Embodiment 3

[0058] Catalyst C:

[0059] polymerization

[0060] Styrene, divinylbenzene, porogen, and initiator are weighed into the mixing tank, and stirred for 2.0 hours to make the material and liquid mix evenly and become the oil phase. Add water, main dispersant, auxiliary dispersant and water-phase polymerization inhibitor into the polymerization kettle, stir and heat up to 45°C to dissolve completely, then add mixed monomer, adjust the stirring speed to 140 rpm according to the dispersion of the monomer, And slowly raise the temperature to 80°C for polymerization. After reacting for 12 hours, cool and discharge the polymer, wash the polymer three times with hot water and cold water respectively, and separate the white balls.

[0061] extract

[0062] Put the white ball into the extraction kettle, add excess toluene to the distillation kettle and heat it to evaporate the solvent in the kettle, and flow into the extraction kettle after condensation, the solvent will partially diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com