Liquid metal negative pole piece as well as preparation method and application thereof

A negative electrode pole piece and liquid metal technology, which is applied in the field of lithium ion solid-state battery liquid metal negative pole piece and its preparation, can solve the problems of large interface impedance of all solid electrolytes, lower lithium ion conductivity, and lower lithium ion density. Improve the critical current density, the preparation method is simple and efficient, and the effect of solving the interface contact problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

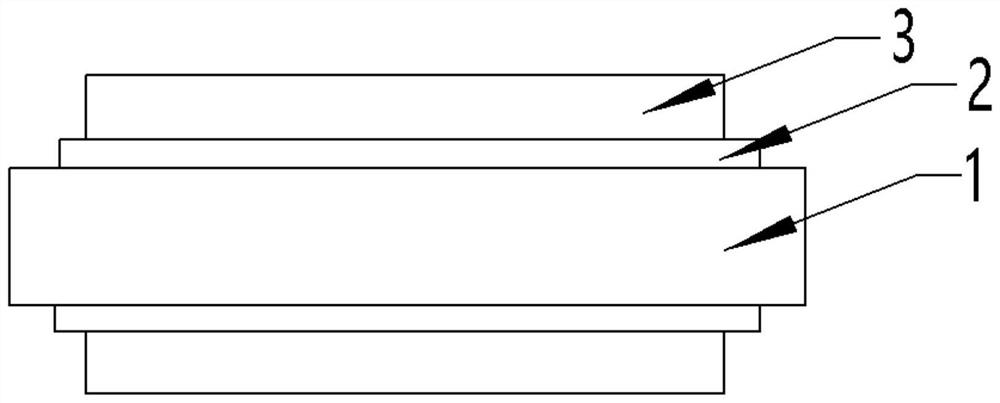

[0039] This embodiment provides a method for preparing a solid-state battery containing a liquid metal negative pole piece:

[0040] Step 1: Take LLTO with a thickness of about 1mm and a diameter of 10mm as solid electrolyte 1, use LLTO to polish, ultrasonically clean, and heat treat at 500°C for 3 hours to remove LiCO 3, LiOH, the electrolyte is purged with nitrogen to remove impurities, dust, etc. remaining on the surface;

[0041] Step 2: Melt pure sodium and pure potassium and transfer them into a glass bottle according to the ratio of 1:1, heat to a single-phase liquid state and mix evenly and cool to prepare Na-K alloy, namely liquid alloy 2;

[0042] Step 3: Take a lithium metal sheet 3 with a diameter of 8 mm, and apply 4 μL of Na-K alloy, that is, liquid alloy 2, to one side of the lithium sheet, and coat evenly;

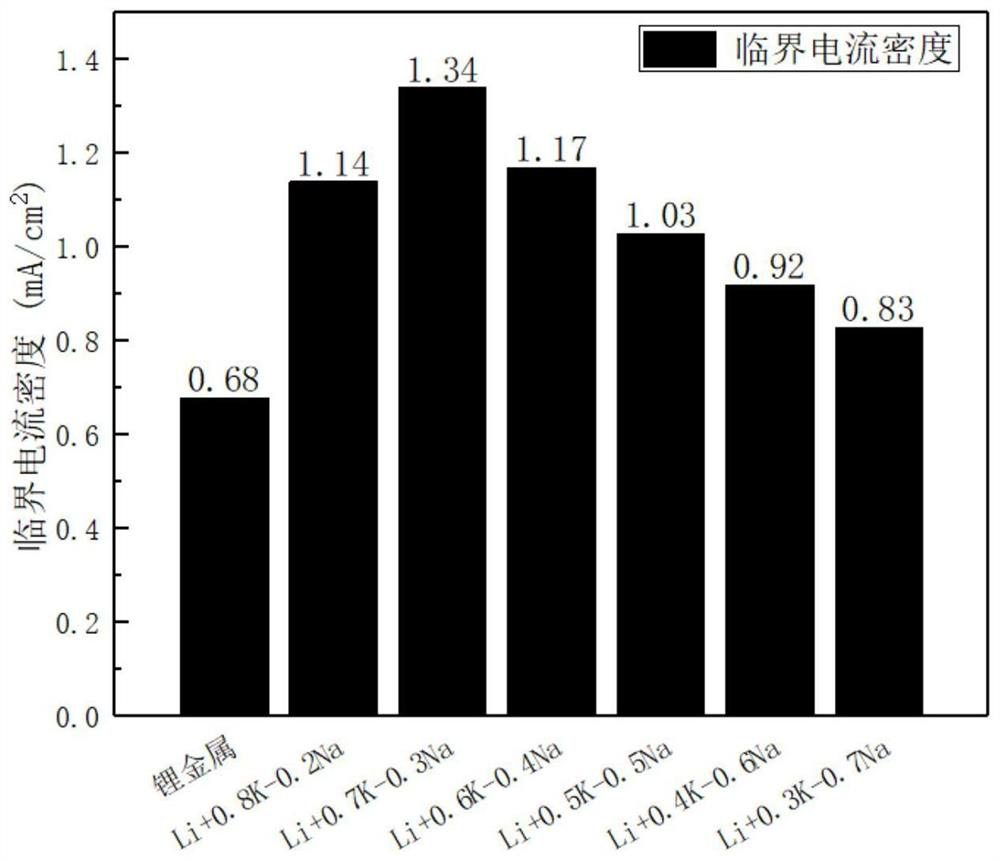

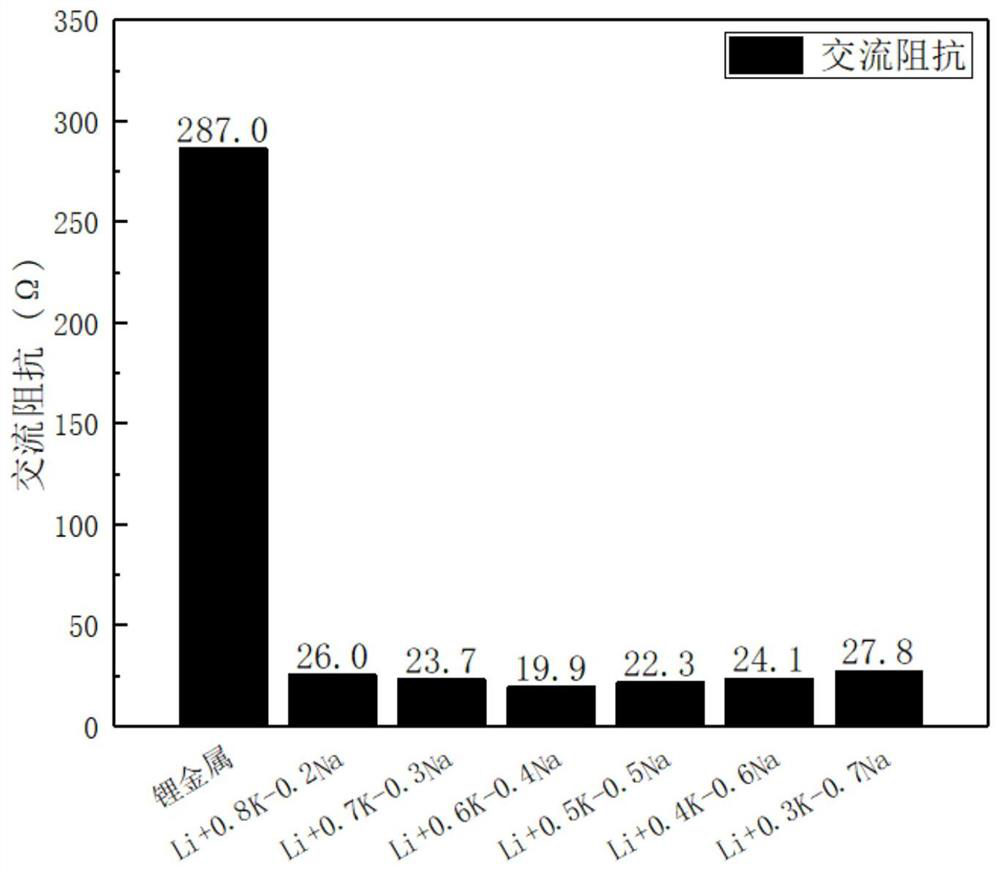

[0043] Step 4: Contact the Na-K alloy-coated side of the lithium metal sheet with the LLTO sheet, assemble a pair of lithium batteries, measure the critic...

Embodiment 2

[0045] This embodiment provides a method for preparing a solid-state battery containing a liquid metal negative pole piece:

[0046] Step 1: Take LLZTO with a thickness of about 1mm and a diameter of 12mm as solid electrolyte 1, use LLZTO to polish, ultrasonically clean, and heat treat at 500°C for 3 hours to remove LiCO 3 , LiOH, the electrolyte is purged with nitrogen to remove impurities, dust, etc. remaining on the surface;

[0047] Step 2: After melting pure tin and pure copper, transfer them into a glass bottle according to the ratio of 4:1, heat them until they are in a single-phase liquid state, mix them evenly and cool them down to prepare a Cu-Sn alloy, namely Liquid Alloy 2;

[0048] Step 3: Take a lithium metal sheet 3 with a diameter of 9 mm, and coat 5 μL of Cu-Sn alloy on one side of the lithium sheet, and coat evenly;

[0049] Step 4: Contact the Cu-Sn alloy-coated side of the lithium metal sheet with the LLZTO sheet, assemble a lithium battery, measure the cr...

Embodiment 3

[0051] This embodiment provides a method for preparing a solid-state battery containing a liquid metal negative pole piece:

[0052] Step 1: Take a PEO polymer electrolyte with a thickness of about 1mm and a diameter of 11mm as the solid electrolyte 1. Use the PEO polymer electrolyte to polish, ultrasonically clean, and heat treat at 500°C for 3 hours to remove LiCO 3 , LiOH, the electrolyte is purged with nitrogen to remove impurities, dust, etc. remaining on the surface;

[0053] Step 2: After melting pure aluminum and pure copper, transfer them into a glass bottle according to the ratio of 4:1, heat them until they are in a single-phase liquid state, mix them evenly and cool them down, and prepare an Al-Cu alloy, that is, liquid alloy 2;

[0054] Step 3: Take a lithium metal sheet 3 with a diameter of 9 mm, and coat 5 μL of Al-Cu alloy on one side of the lithium sheet, and coat evenly;

[0055] Step 4: Contact the Al-Cu alloy-coated side of the lithium metal sheet with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com