Unconventional doping method for efficiently improving carrier concentration of semiconductor

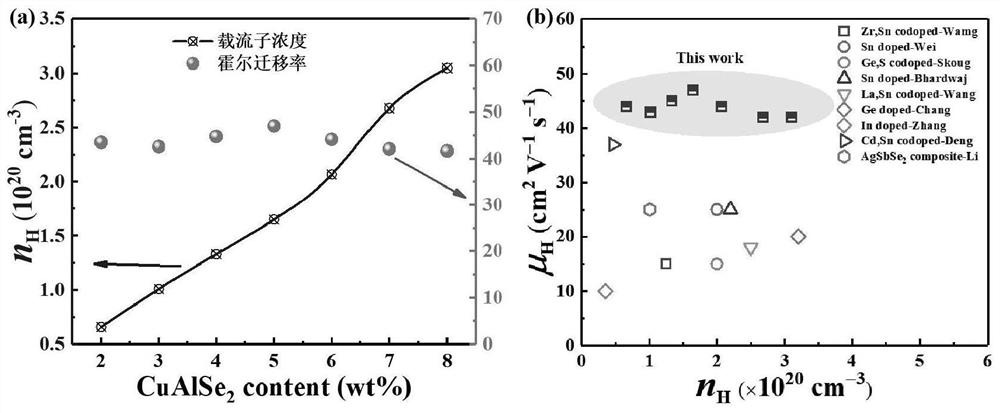

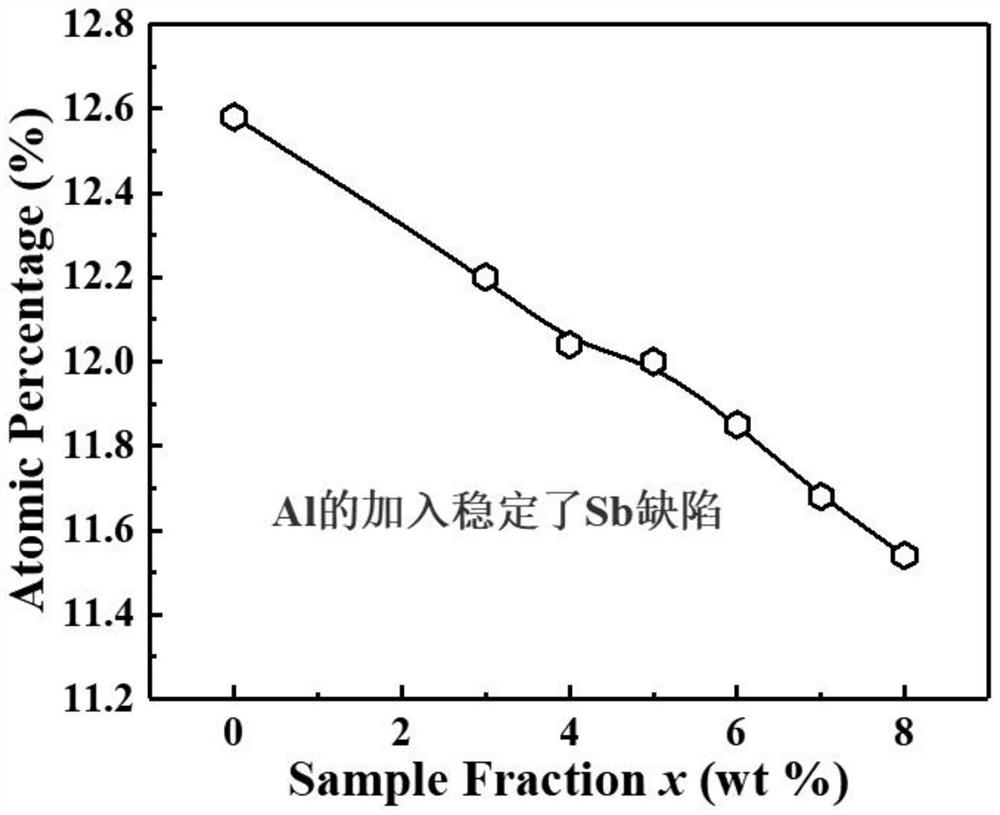

A technology of carrier concentration and semiconductor, which is applied in the manufacture/processing of thermoelectric devices, and lead wire materials of thermoelectric devices, can solve the problems of poor conductivity and low semiconductor doping efficiency, and achieve excellent electrical properties, Improve electrical performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An unconventional doping method for increasing the concentration of semiconductor carriers with high efficiency. The preparation steps are as follows: 3 Sb 1-δ Se 4 -x CuAlSe 2 (x=2wt%), accurately weigh raw materials in a glove box with an argon-protected environment, place in a quartz tube to vacuum seal the tube after weighing; the quartz tube with raw materials is placed in a horse-boiler, and the horse-boiler is heated at 5°C min -1 Slowly raise the temperature to 900°C, keep it warm for 12 hours, let the raw materials fully react, then take out the quartz tube, quench it in cold water and cool it quickly, then anneal at 450°C, pour the annealed sample into an agate grinding bowl, and grind it into powder carefully shape, and then made into a dense bulk material by hot pressing sintering technology.

Embodiment 2

[0031] An unconventional doping method for increasing the concentration of semiconductor carriers with high efficiency. The preparation steps are as follows: 3 Sb 1-δ Se 4 、CuAlSe 2 (x=3wt%), the raw materials were accurately weighed in a glove box with an argon-protected environment, and the rest of the operating steps were the same as in Example 1.

Embodiment 3

[0033] An unconventional doping method for increasing the concentration of semiconductor carriers with high efficiency. The preparation steps are as follows: 3 Sb 1-δ Se 4 、CuAlSe 2 (x=4wt%), the raw materials were accurately weighed in a glove box with an argon-protected environment, and the rest of the operating steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com