Basalt fiber modified polymer cement waterproof coating

A technology of basalt fiber and waterproof coating, which is applied in the direction of cement coating, anti-corrosion coating, coating, etc., can solve the problems of coating film breakage or micro cracks, large temperature difference of waterproof coating, etc., to improve acid and alkali resistance and reduce cracking The probability of improving the effect of temperature stress problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The specific operation includes the following steps:

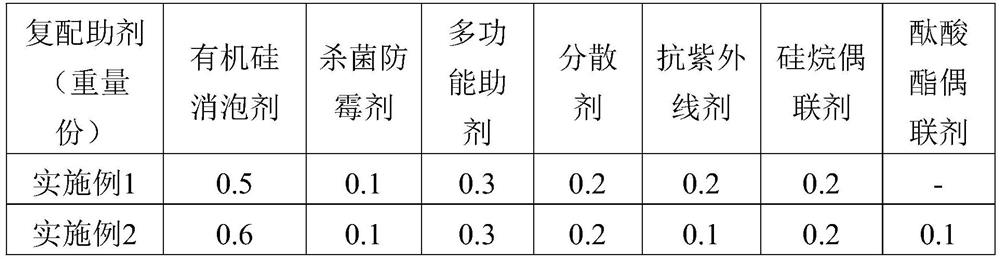

[0048] Weigh 1.5 parts of compounding aids (0.5 parts of defoamer, 0.1 part of bactericide and antifungal agent, 0.3 part of multifunctional auxiliary agent, 0.2 part of dispersant, 0.2 part of anti-ultraviolet agent, 0.2 part of silane coupling agent) and 5 parts of water 0.5 parts of compound thickener (0.2 part of hydroxyethyl cellulose, 0.3 part of lignocellulose) and 5 parts of water and stirred evenly for use;

[0049] Add 85 parts of high molecular polymer emulsion (pure acrylic emulsion) to the stirring pot, stir at 600r / min for 5min, add the stirred compound additive, stir at 1000r / min for 20min, then add the stirred compound additive Thickener and the remaining 3.0 parts of water, stirred at 1200r / min for 20 minutes, and discharged to obtain the exposed polymer cement waterproof coating water agent.

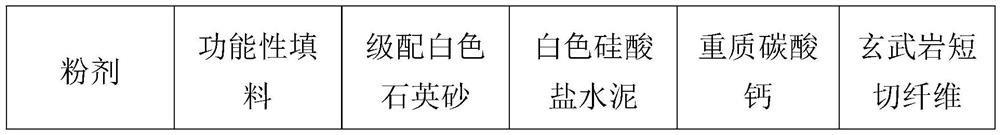

[0050] Weigh 14 parts of functional filler (1 part of nano-silica, 5 parts of titanium dioxide, 3 parts o...

Embodiment 2

[0053] The specific operation includes the following steps:

[0054] Take by weighing 1.6 parts of compounding aids (0.6 part of defoamer, 0.1 part of bactericide and antifungal agent, 0.3 part of multifunctional auxiliary agent, 0.2 part of dispersant, 0.1 part of anti-ultraviolet agent, 0.2 part of silane coupling agent, phthalate 0.1 part of coupling agent) and 5 parts of water were stirred evenly for later use; 0.1 part of hydroxyethyl cellulose and 5 parts of water were weighed and stirred evenly for later use;

[0055] Add 80 parts by weight of high-molecular polymer emulsion (65 parts of pure acrylic emulsion, 15 parts of vinyl acetate emulsion) into the stirring pot, stir at 600r / min for 5min, add the compounding aid that has been stirred, and stir at 1000r / min After 20 minutes, add the stirred compound thickener and the remaining 8.3 parts of water, stir at 1000r / min for 20 minutes, and discharge to obtain the exposed polymer cement waterproof coating water agent.

...

Embodiment 3

[0059] The difference with embodiment 1 is:

[0060] 100 parts by weight of each component of the water preparation is calculated as: 90 parts of high molecular polymer emulsion, 0.5 parts of compounding auxiliary agent, 0.1 part of compounded thickener, and 9.4 parts of water.

[0061] The specific mass parts of each component in the polymer emulsion are: 60 parts of pure acrylic emulsion, 15 parts of vinyl acetate emulsion, and 15 parts of silicon acrylic emulsion.

[0062] The specific parts by weight of each component in the compounding auxiliary agent are: 0.1 part of organosilicon defoamer, 0.1 part of dispersant, 0.2 part of bactericidal preservative, and 0.1 part of multifunctional auxiliary agent.

[0063] The specific parts by weight of each component in the compound thickener are: 0.05 part of hydroxymethyl cellulose and 0.05 part of hydroxyethyl cellulose.

[0064] Add polymer emulsion and stir for 5 minutes under the condition of 500r / min, add compound auxiliary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com