Paper machine clothing with edge reinforcement

a technology of edge reinforcement and paper machine, applied in the field of clothing, can solve the problems of pet threads falling off, coatings known from the prior art, and often not adhering firmly to the threads of the cloth, etc., and achieve the effects of increasing temperature stress, increasing abrasion, and increasing temperature stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

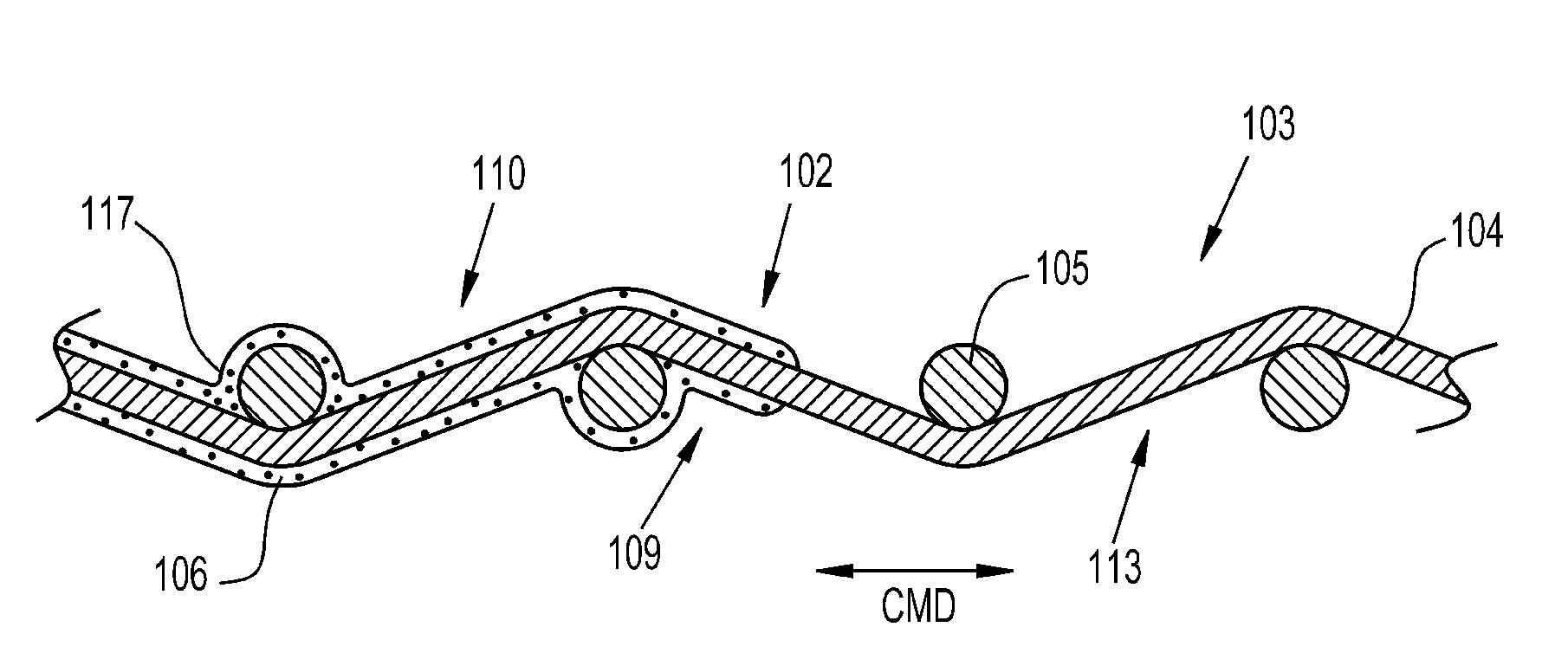

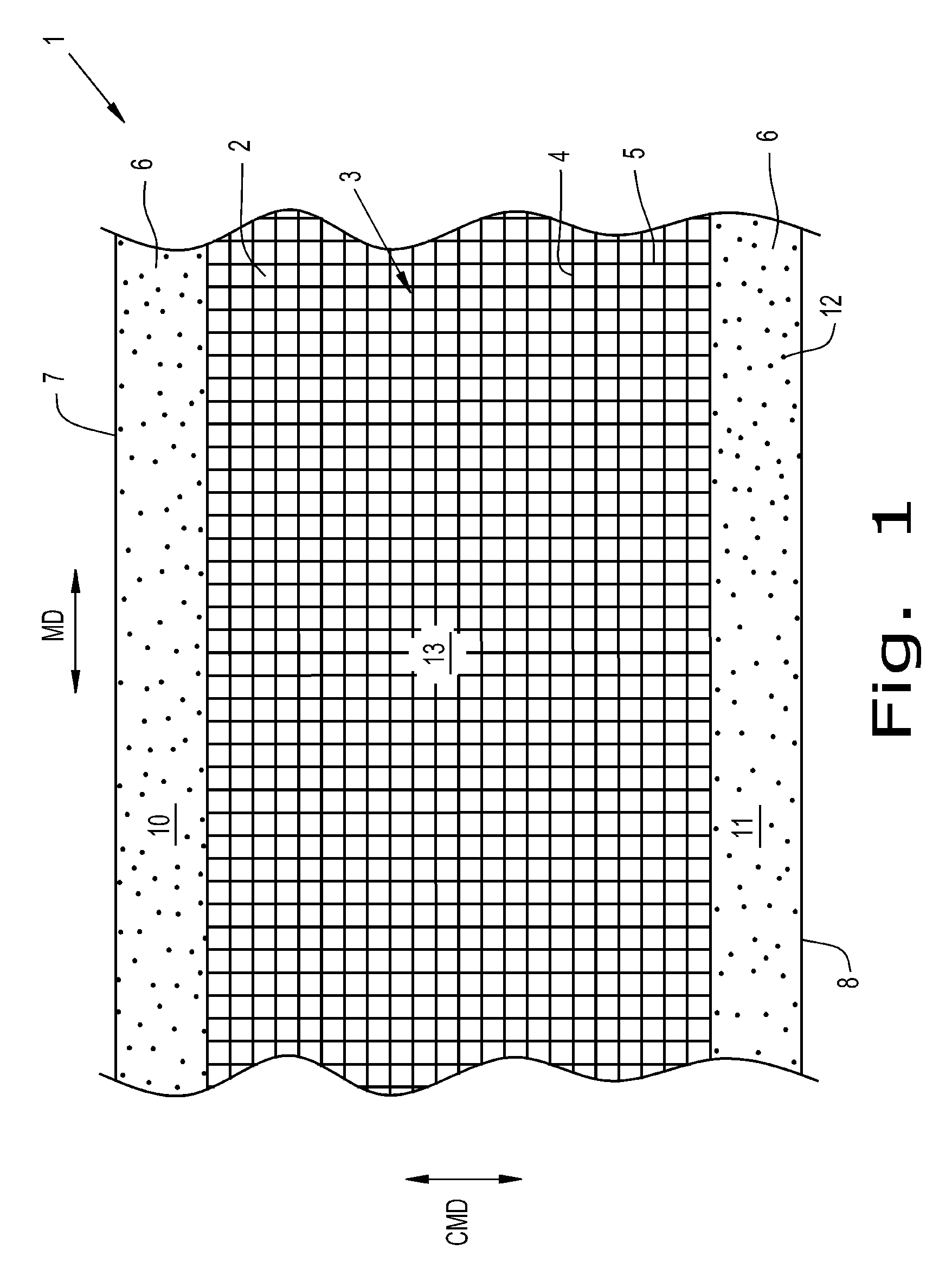

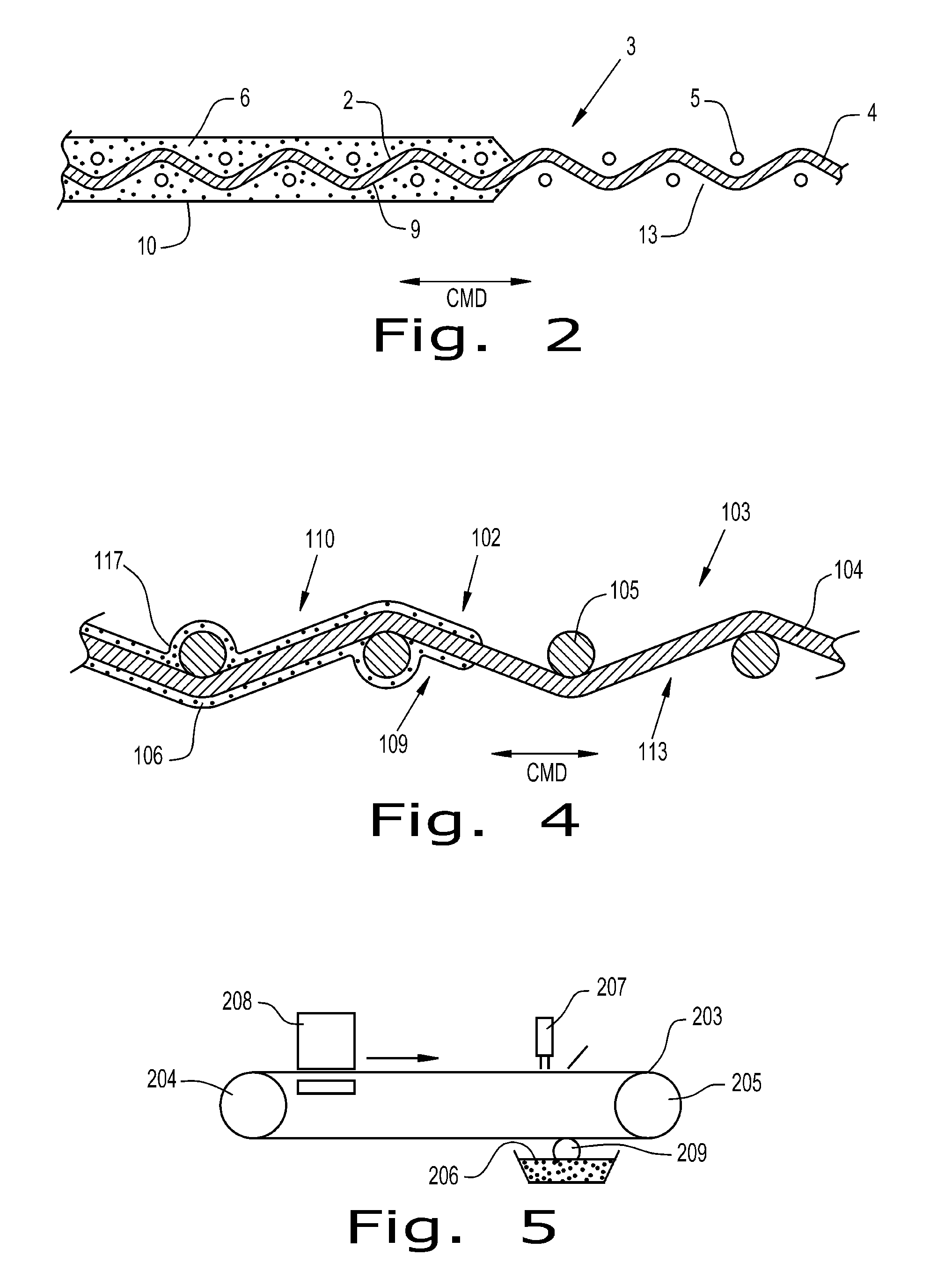

[0042]Referring now to the drawings, and more particularly to FIG. 1, there is shown an embodiment of inventive clothing 1 in a plan view of upper side 2.

[0043]The represented clothing 1 is a TAD mesh. Mesh 1 has a flat basic structure which is formed by permeable fabric 3 woven from PET threads 4 and 5.

[0044]In addition mesh 1 includes coating 6 which is applied respectively in the region of two longitudinal edges 7 and 8 extending in the machine direction (“MD direction”) and in edge areas 10, 11 on fabric 3 on upper side 2 and on lower side 9 (shown only in FIG. 2). Between two coated edge areas 10, 11 is an uncoated area 13.

[0045]According to the present invention, coating 6 includes a polymer material, which in the example in question is formed by a two-component elastomer polyurea and nanoparticles 12 of boronitride. The wear stability of coating 6 is increased by boronitride nanoparticles 12.

[0046]Coated edge areas 10, 11 extend in this case respectively by approximately 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com