Photosensitive polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of photosensitive polypropylene material and its preparation, can solve the problems such as difficult to improve the effect of stain cleaning, and achieve the effect of promoting easy cleaning effect, low process condition requirements, and few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

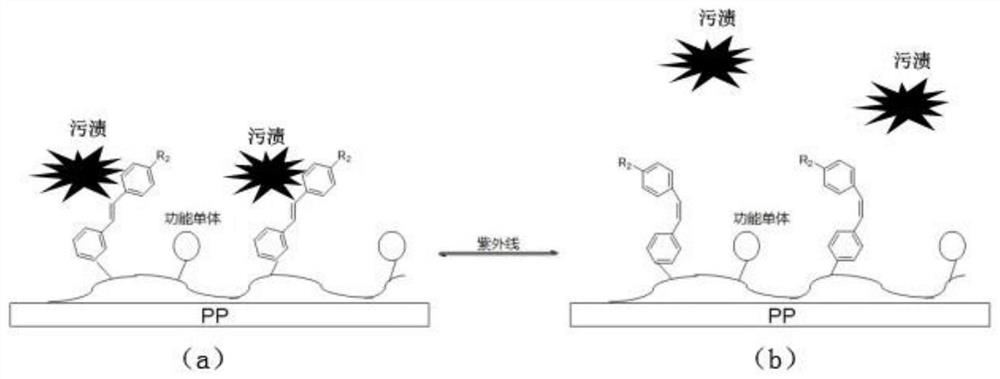

Problems solved by technology

Method used

Image

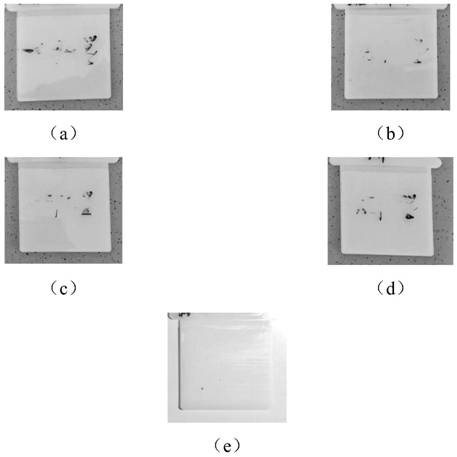

Examples

Embodiment 1

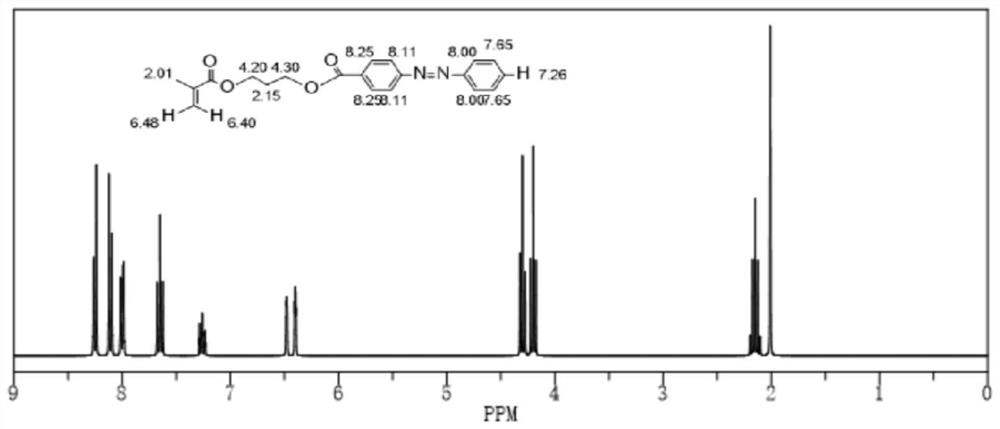

[0075] (1) Preparation of azobenzene functional monomer: add 0.5g triethylamine in 500mL chloroform, then add 50g glycidyl methacrylate (A), add functional azobenzene compound (B), the moles of both The ratio is A:B=0.9. After dissolving and stirring evenly, heat to 50°C and react at a constant temperature for 8 hours, then cool to room temperature, adjust the pH value to neutral with hydrochloric acid, and remove the solvent by rotary evaporation to obtain a crude product, which is reconstituted with ethanol. Crystallization and purification to obtain the final product azobenzene functional monomer. Wherein the molecular formula of the functional azobenzene compound (B) is:

[0076]

[0077] Among them, R 2 for a hydrogen atom.

[0078] (2) Preparation of photosensitive functionalized polypropylene: stir polypropylene, functional monomers, azobenzene functional monomers and peroxides evenly, then add them to a twin-screw extruder for melt extrusion, and use reactive extr...

Embodiment 2

[0083] (1) Preparation of azobenzene functional monomer: add 0.05g triphenylphosphine in 500mL benzene, then add 50g glycidyl methacrylate (A), add functional azobenzene compound (B), both The molar ratio is A:B=1.0, after dissolving and stirring evenly, heat to 80°C, react at constant temperature for 8 hours, then cool to room temperature, use hydrochloric acid to adjust the pH value to neutral, and remove the solvent by rotary evaporation to obtain a crude product, which is carried out with ethanol Purify by recrystallization to obtain the final product azobenzene functional monomer. Wherein the molecular formula of the functional azobenzene compound (B) is:

[0084]

[0085] Among them, R 2 for -CH 3 .

[0086] (2) Preparation of photosensitive functionalized polypropylene: stir polypropylene, functional monomers, azobenzene functional monomers and peroxides evenly, then add them to a twin-screw extruder for melt extrusion, and use reactive extrusion to obtain the pho...

Embodiment 3

[0090] (1) Preparation of azobenzene functional monomer: add 0.25g tetrabutylammonium bromide in 500mL xylene, then add 50g glycidyl methacrylate (A), add functional azobenzene compound (B), The molar ratio of the two is A:B=0.95. After dissolving and stirring evenly, heat to 150° C., react at a constant temperature for 8 hours, then cool to room temperature, use hydrochloric acid to adjust the pH value to neutral, and remove the solvent by rotary evaporation to obtain a crude product. Ethanol is used for recrystallization and purification to obtain the final product azobenzene functional monomer. Wherein the molecular formula of the functional azobenzene compound (B) is:

[0091]

[0092] Among them, R 2 for -OH.

[0093] Preparation of photosensitive functionalized polypropylene: mixing polypropylene, functional monomers, azobenzene functional monomers and peroxides evenly, adding them to a twin-screw extruder for melt extrusion, and using reactive extrusion to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com