Method for preparing aerated board by utilizing multistage aluminum powder and aerated board prepared by using method

A technology of sheet and aluminum powder, applied in application, household appliances, ceramic products, etc., can solve the problems of fast reaction speed of aluminum powder and alkali, uniform dispersion of air bubbles unfavorable for hollow structure, adverse effect on mechanical strength of air-entrained concrete plates, etc. Achieve the effect of avoiding uneven distribution of bubbles, inhibiting condensation and hardening, and improving crack resistance and compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

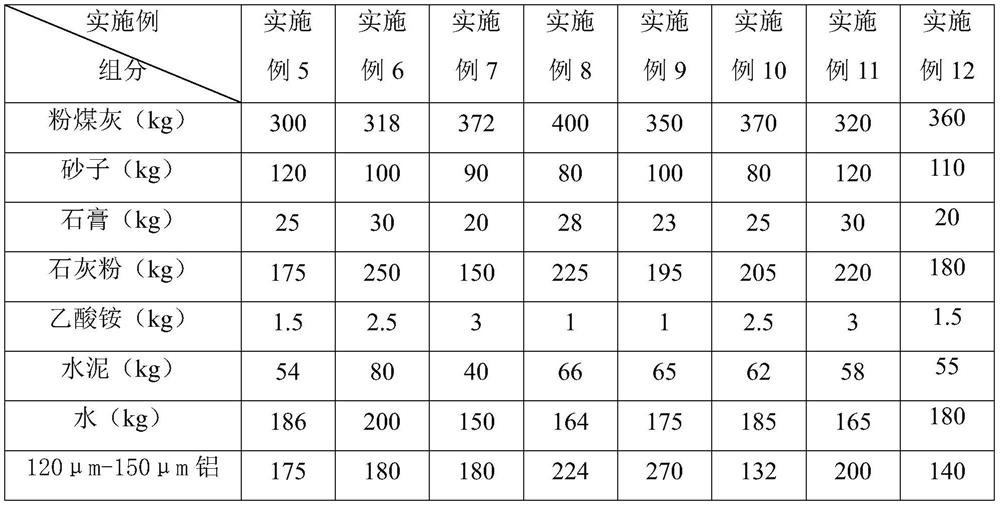

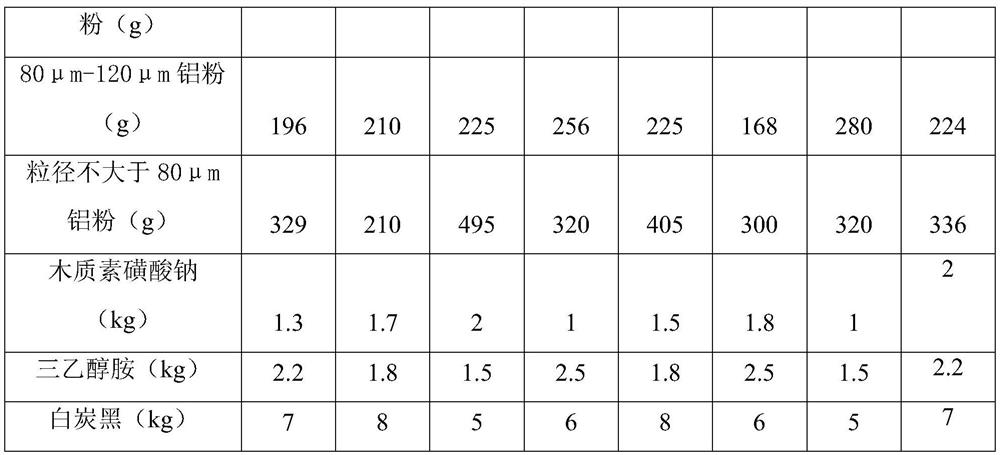

Examples

Embodiment 1

[0037] Embodiment 1: a kind of method that utilizes multi-stage aluminum powder to prepare aerated sheet material, comprises the following steps:

[0038]S1 Mixing: Weigh 350kg of fly ash and 100kg of sand, mix them evenly, use a ball mill to grind them, and sieve them with a sieve with an aperture of 200μm. The particles with a particle size larger than 200μm continue to be ball-milled until they are not larger than 200μm; then add 25kg of gypsum, 200kg of lime powder, 2kg of ammonium acetate, 60kg of cement, 2kg of triethanolamine and 6kg of white carbon black were mixed evenly to obtain a mixture.

[0039] S2 pulping: Take 200g of aluminum powder with a particle size of 120μm-150μm, add 240g of aluminum powder with a particle size of 80μm-120μm and 360g of aluminum powder with a particle size of not more than 80μm, and mix evenly to prepare multi-level composite aluminum powder. Cool the water to 8°C with a refrigerator. Add 170kg of water at 8°C to the mixture prepared in...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that embodiment 2 does not add sodium lignosulfonate, and others are consistent with embodiment 1.

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is that no triethanolamine is added in embodiment 3, and the others are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com