Method and device for preparing ammonia

A technology of ammonia gas and absorbent, applied in the direction of ammonia preparation/separation, chemical instruments and methods, ammonia compounds, etc., can solve the problems of high investment and operating costs, and achieve the effect of low operating costs and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

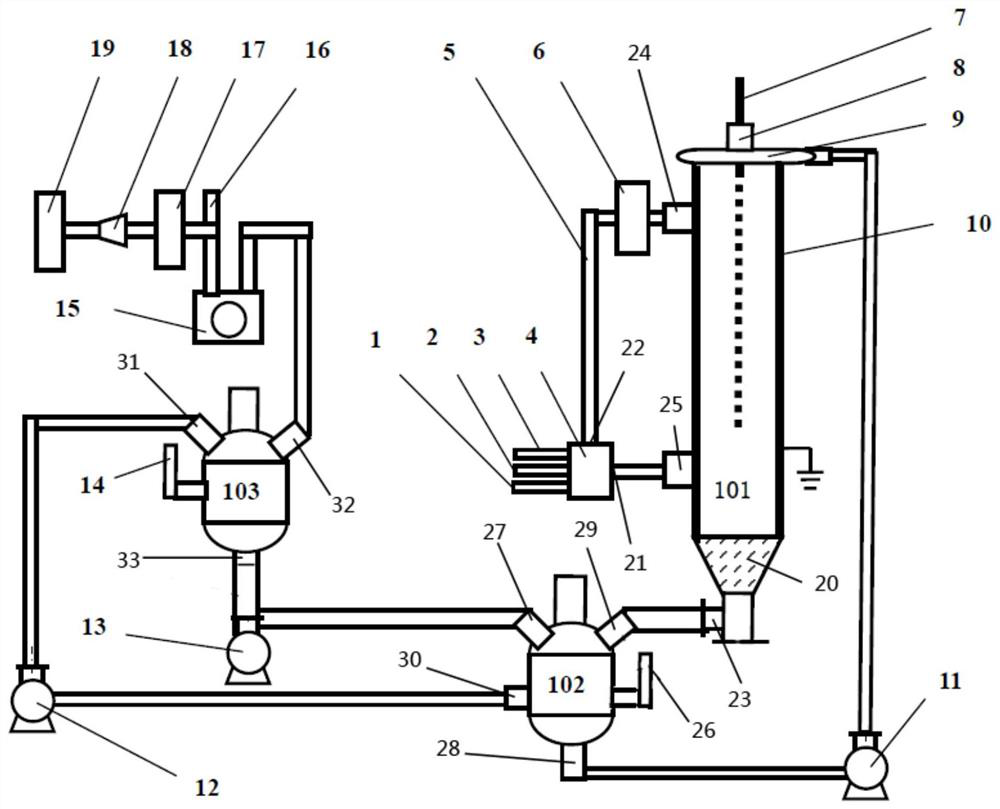

[0048] Embodiment 1: a kind of device of the method for preparing ammonia is as figure 1 shown. The gas discharge reaction absorber is straight cylindrical, the material is Hastelloy alloy, the height of the reactor is about 300mm, the inner diameter is about Φ60mm, the size of the central electrode rod is Φ8×300, the material is also alloy, the central electrode rod is connected with the high voltage power supply, and the cylinder body Grounded, the effective length of the gas discharge area is about 150mm. The upper part of the reactor is equipped with an absorption slurry distributor flow guide device, so that the surface of the ground electrode plate on the inner wall of the reactor cylinder forms a uniform absorbent slurry film, and the absorbent is collected by the circulation tank at the lower part of the reactor and then circulated through the circulation pump use.

[0049] The volume ratio of nitrogen and hydrogen in the initial intake air is 1:3, the rest is carrie...

Embodiment 2

[0050] Example 2: In Example 1, the volume ratio of nitrogen and hydrogen in the initial intake air is 9:1 (nitrogen doubles as carrier gas), the electrode power supply mode is changed to DC power supply, the cylinder is grounded, the voltage is about 30kV, and the power supply power is about 50W. Other conditions and operations are basically the same as in Example 1. Experimental results The ammonia conversion rate of nitrogen is about 4%.

Embodiment 3

[0051] Example 3: The reactor electrode is powered by an AC power supply, and the reactor cylinder is connected to the other pole of the AC power supply, with a voltage of about 30kV, a frequency of 50Hz, and a power supply of about 50W. Other conditions are with embodiment 1. Experimental results The ammonia conversion rate of nitrogen is about 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com