High-flux polypeptide synthesis device and use method thereof

A peptide synthesis and fixation device technology, which is applied in peptide preparation methods, chemical instruments and methods, peptides, etc., can solve problems such as inability to participate in reactions, harsh production environments, and low synthesis efficiency, and achieve stable control of reaction conditions and save raw materials and reagents, the effect of stable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

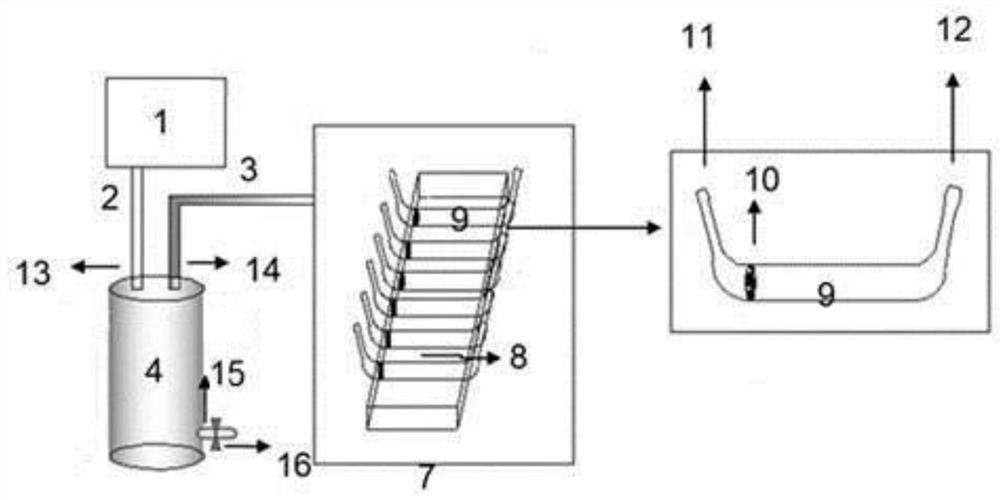

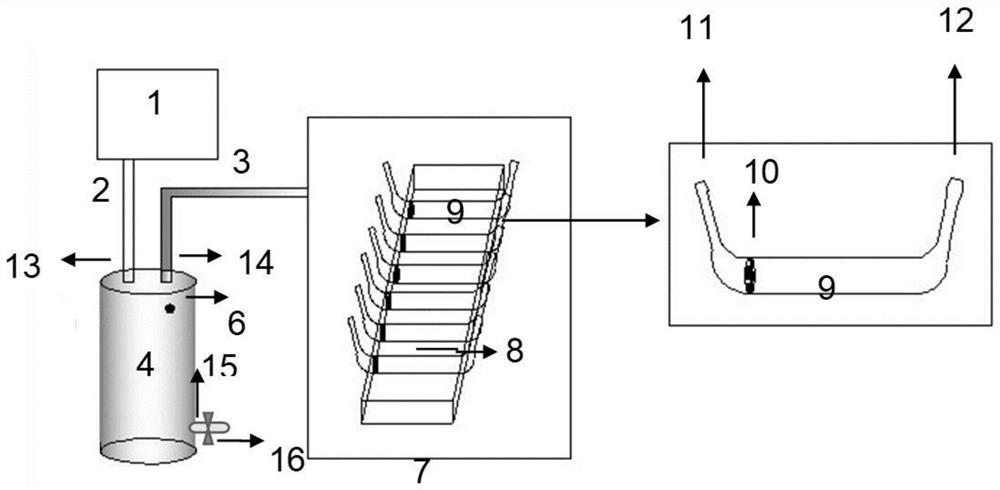

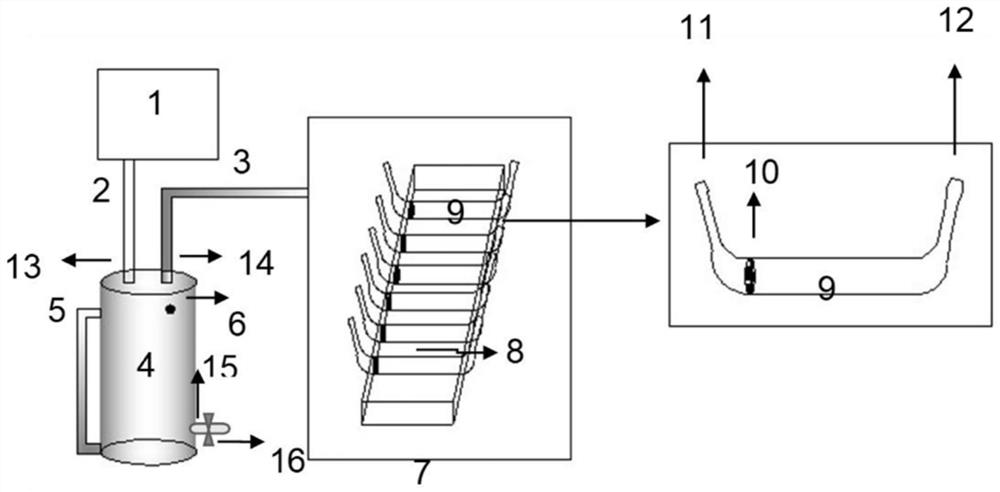

[0064] Such as figure 1 , a high-throughput polypeptide synthesis device, including a polypeptide "boat" type reactor 9 , a reactor fixture 8 , a constant temperature shaker 7 , a vacuum pump 1 and a waste liquid tank 4 .

[0065] The polypeptide "boat" type reactor 9 is similar in appearance to a "boat" type, and is made of glass slush molding, with a built-in filter sand core plate 10, a liquid discharge port 11 at one end of the sand core plate 10, and a feeding port 12 slightly larger than The discharge port 11 is of the same height, and each "boat" type reactor is an independent individual without interfering with each other;

[0066] The material of the reactor fixture 8 is corrosion-resistant lightweight foam cotton, and the size of each hole depends on the size of the reactor, and each fixture 8 can accommodate 3-12 reactors;

[0067] The shaker 7 can be shaken in any direction, such as up and down, left and right regular or irregular shaking, etc., and the speed can ...

Embodiment 2

[0072] As an improvement of the present invention, the shaker is a constant temperature shaker. By setting the temperature, humidity and rotation speed of the shaker, the polypeptide "boat" type reactor 9 can be kept in a constant temperature and dry state, and shaken. The solution is mixed evenly, which is conducive to the stability and efficient synthesis of peptides.

Embodiment 3

[0074] As an improvement of the present invention, such as figure 2 As shown, the waste liquid tank 4 has a built-in pressure device 6, which can warn that the negative pressure in the waste liquid tank is too high and improve safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com