Preparation method of zinc oxide nanowire modified nanofiber filtering membrane

A zinc oxide nanowire and nanofiber membrane technology, applied in the field of textile materials, can solve problems such as less industrial antibacterial use, and achieve the effects of low cost, high porosity, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a nanofiber filter membrane modified by zinc oxide nanowires, comprising the steps of:

[0055] (1) Dissolve 0.30g of zinc acetate dihydrate completely in a mixed solvent of 15mL N,N-dimethylformamide and 5mL of acetone, and then add 3.40g of it with a molecular weight of about 3.0×10 5 The polyvinylidene fluoride was fully stirred for 16 hours, then heated and stirred in a water bath at 50°C for 8 hours to obtain a spinning solution.

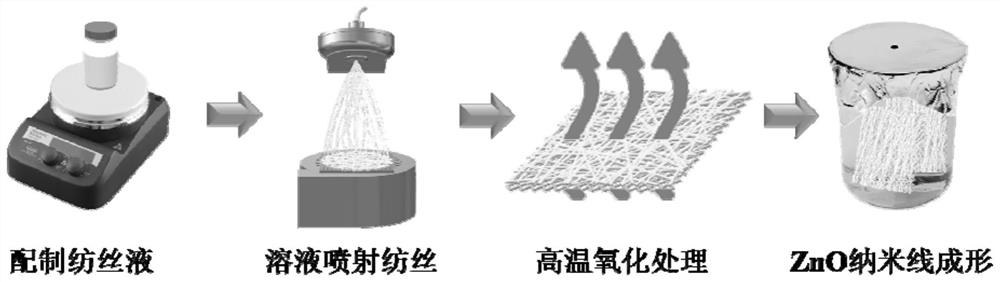

[0056] (2) Utilize solution jet spinning technology to spin the spinning solution in step (1) into nanofiber film, adopt stainless steel net to receive fiber film; Wherein, the preparation process of described solution jet spinning technology is as follows figure 1 , followed by the preparation of spinning solution, solution jet spinning, high temperature treatment and forming of zinc oxide nanowires; spinning parameters: spinning solution advancing rate of 2.0mL / h, spinning air pressure of 0.20MPa, receiving dista...

Embodiment 2

[0065] A preparation method of a nanofiber filter membrane modified by zinc oxide nanowires, comprising the steps of:

[0066] (1) Dissolve 0.30g of zinc acetate dihydrate completely in a mixed solvent of 15mL N,N-dimethylformamide and 5mL of acetone, and then add 3.40g of it with a molecular weight of about 3.0×10 5 The polyvinylidene fluoride powder was fully stirred for 16 hours, then heated and stirred in a water bath at 50°C for 8 hours to obtain a spinning solution.

[0067] (2) Spinning the spinning solution in step (1) into a nanofiber membrane by using a solution jet spinning technology, and adopting a stainless steel mesh to receive the fiber membrane. Spinning parameters: the propulsion rate of the spinning solution is 2.5mL / h, the spinning air pressure is 0.25MPa, and the receiving distance is 60cm.

[0068] (3) Place the nanofiber membrane in step (2) in a blast oven and heat at 150° C. for 12 hours to obtain a polyvinylidene fluoride nanofiber membrane loaded wi...

Embodiment 3

[0071] A preparation method of a nanofiber filter membrane modified by zinc oxide nanowires, comprising the steps of:

[0072] (1) Completely dissolve 0.30g of zinc acetate dihydrate and 0.01g of copper nitrate in a mixed solvent of 15mL N,N-dimethylformamide and 5mL of acetone, and then add 3.40g of it with a molecular weight of about 3.0×10 5 The polyvinylidene fluoride powder was fully stirred for 16 hours, then heated and stirred in a water bath at 50°C for 8 hours to obtain a spinning solution.

[0073] (2) Spinning the spinning solution in step (1) into a nanofiber membrane by using a solution jet spinning technology, and adopting a stainless steel mesh to receive the fiber membrane. Spinning parameters: the propulsion rate of the spinning solution is 2.0mL / h, the spinning air pressure is 0.20MPa, and the receiving distance is 56cm.

[0074] (3) Place the nanofiber membrane in step (2) in a blast oven and heat at 150° C. for 12 hours to obtain a polyvinylidene fluoride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com