Improved biodegradable porous scaffold particle for injection and preparation method thereof

A technology for biodegradability and injection, applied in the field of porous biodegradable scaffold particles for injection and its preparation, can solve the problems of flow, use restriction, lack of adaptability to organisms, etc., and achieve the effect of a good growth environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

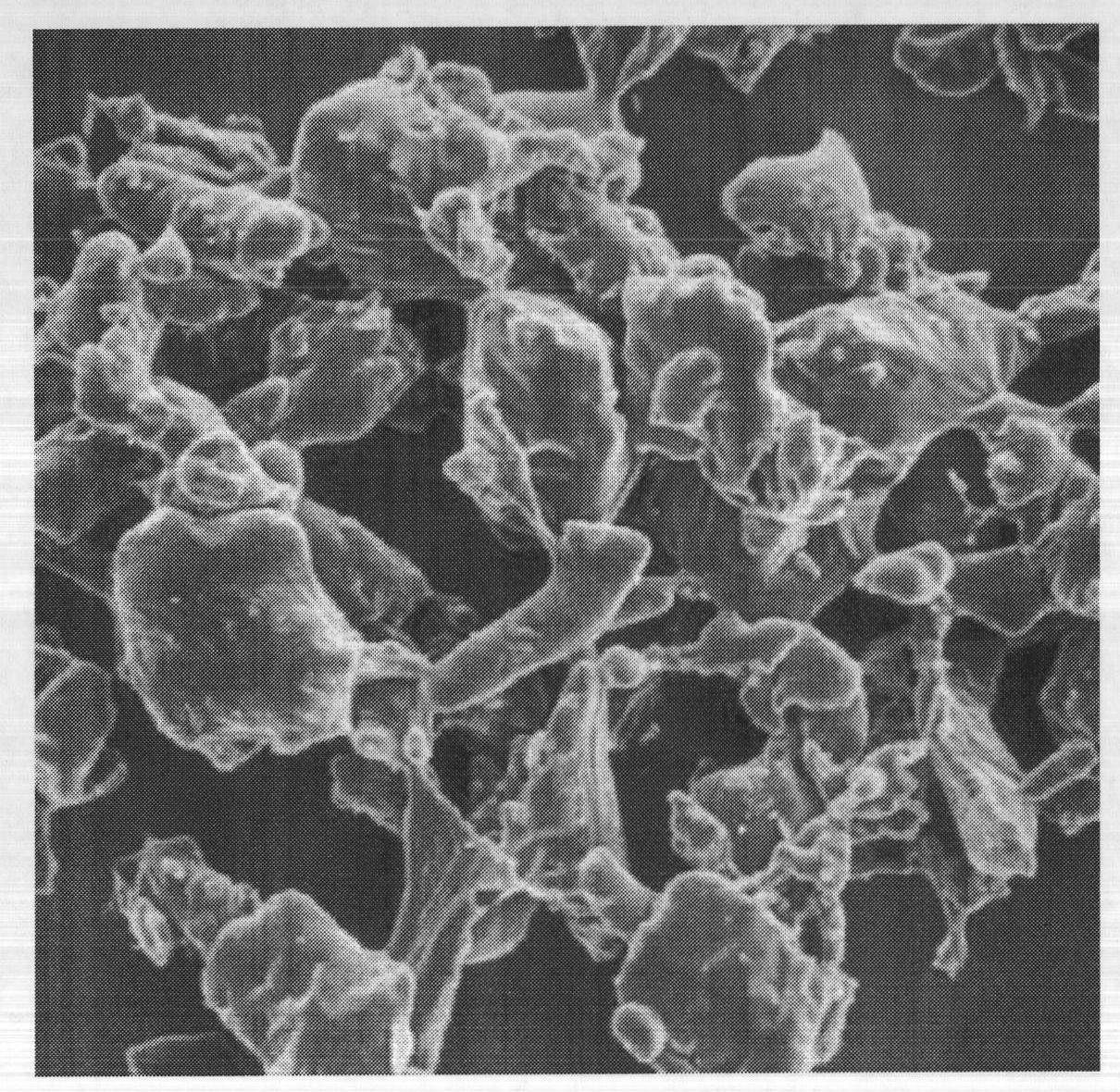

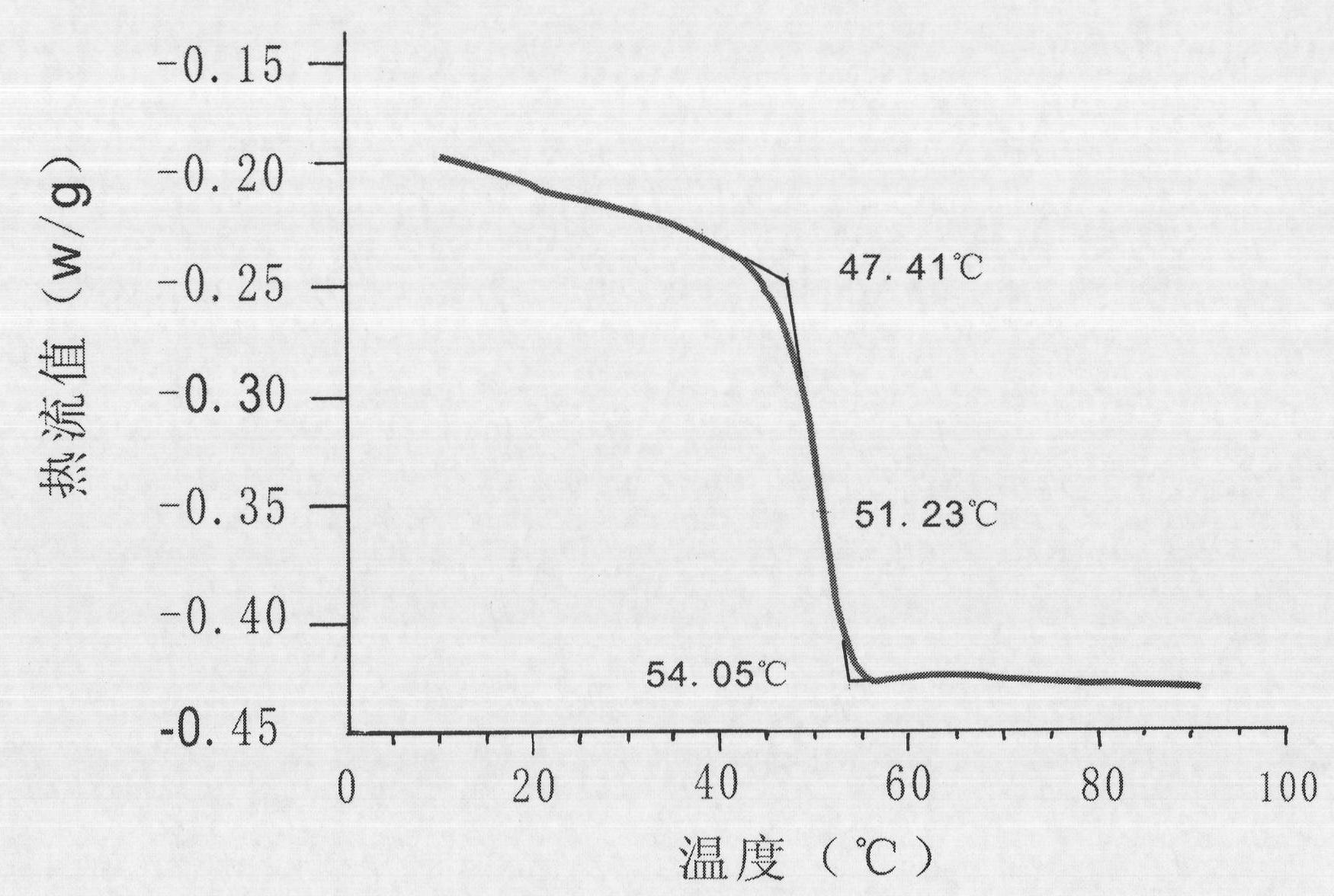

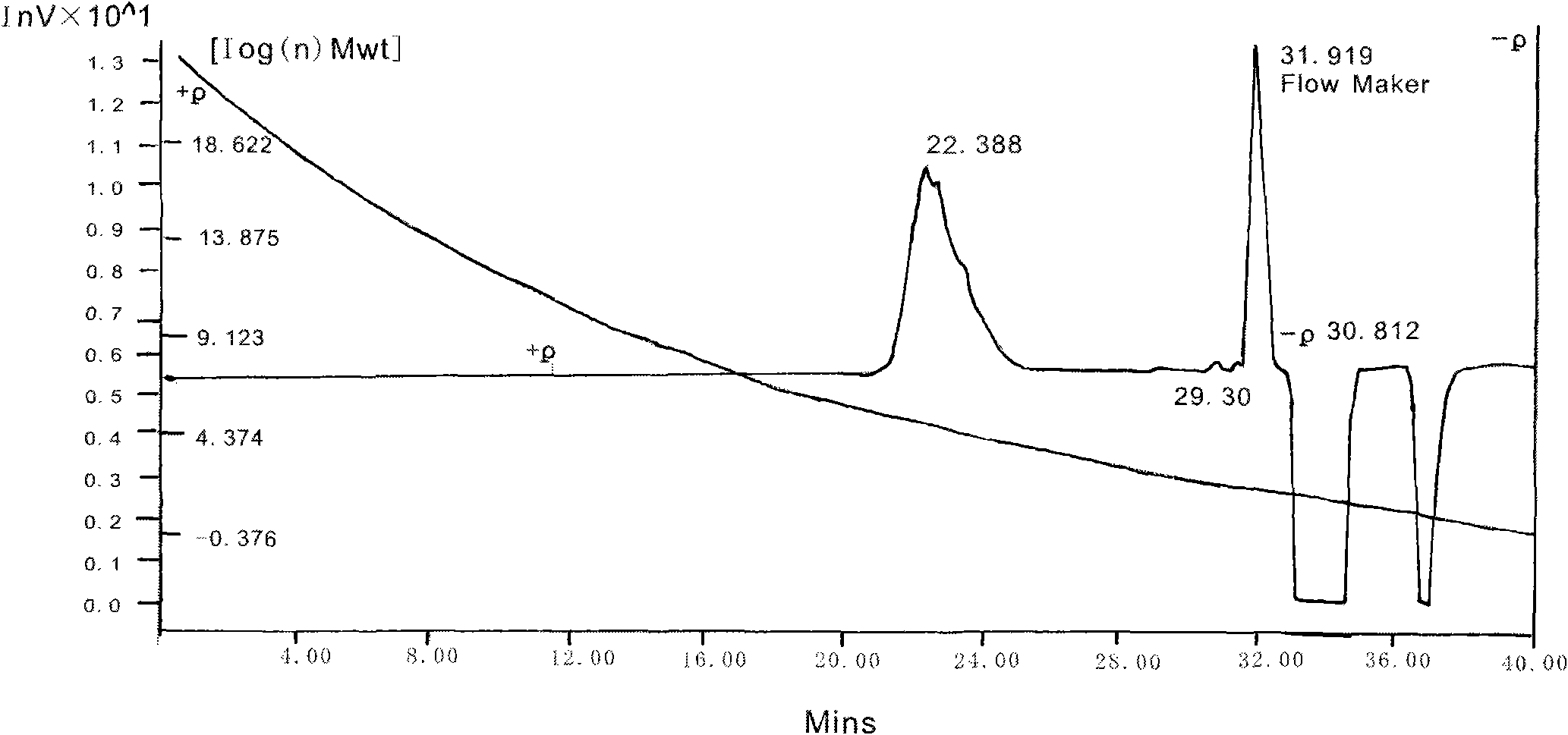

Image

Examples

Embodiment 1

[0039] An improved porous biodegradable scaffold particle for injection, which is mainly composed of biodegradable polymers, wherein the biodegradable polymers are polylactic acid PLA with an average molecular weight range of 150,000.

[0040] A preparation method of an improved porous biodegradable scaffold particle for injection, which comprises the following steps:

[0041] (1) The biodegradable polymer is dissolved in the methylene chloride organic solvent to form an organic solution, the weight percentage of the biodegradable polymer dissolved and the organic solvent is 1.67:98.33, then the organic solution is mixed with water, the organic solution and The weight percentage of water is 30:70;

[0042] (2) Stir the mixture of the solvent solution and water on a mixer at a speed of 2000 rpm for 40 minutes, and maintain the internal temperature of the mixer at 20° C. to form a softened solution;

[0043] (3) Put the softened solution into a mold made of polytetrafluoroethyl...

Embodiment 2

[0047] An improved porous biodegradable scaffold particle for injection, which is mainly composed of biodegradable polymers, wherein the biodegradable polymers are polylactic acid PLA with an average molecular weight range of 10,000.

[0048] A preparation method of an improved porous biodegradable scaffold particle for injection, which comprises the following steps:

[0049] (1) The biodegradable polymer is dissolved in the acetonitrile organic solvent to form an organic solution, the weight percentage of the biodegradable polymer dissolved and the organic solvent is 45:55, then the organic solution is mixed with water, the organic solution and water The weight percentage is 90:10;

[0050] (2) Stir the mixture of the blender solution and water on a blender at a speed of 5000 rpm for 20 minutes, and maintain the internal temperature of the blender at 40° C. to form a softened solution;

[0051] (3) Put the softened solution into a mold made of polytetrafluoroethylene, and fr...

Embodiment 3

[0055] An improved porous biodegradable scaffold particle for injection, which is mainly composed of biodegradable polymers, wherein the biodegradable polymers are polylactic acid PLA with an average molecular weight range of 120,000.

[0056] A preparation method of an improved porous biodegradable scaffold particle for injection, which comprises the following steps:

[0057] (1) The biodegradable polymer is dissolved in the methylene chloride organic solvent to form an organic solution, the weight percentage of the biodegradable polymer dissolved and the organic solvent is 15:85, then the organic solution is mixed with water, the organic solution and The weight percentage of water is 60:40;

[0058] (2) Stir the mixture of the solvent solution and water on a mixer at a speed of 4000 rpm for 30 minutes, and maintain the internal temperature of the mixer at 35° C. to form a softened solution;

[0059] (3) Put the softened solution into a mold made of polytetrafluoroethylene, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com