Iron-nitrogen-carbon composite oxygen reduction catalyst as well as preparation method and application thereof

A technology of iron-nitrogen-carbon and catalyst, which is applied in the field of iron-nitrogen-carbon composite oxygen reduction catalyst and its preparation, and can solve problems such as poor activity and poor catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing an iron-nitrogen-carbon composite oxygen reduction catalyst, comprising the following steps:

[0030] (1) gac, ferrous chloride and nitrogen source are mixed to obtain a mixture;

[0031] (2) Carbonizing the mixture obtained in the step (1) in a nitrogen atmosphere to obtain an iron-nitrogen-carbon composite oxygen reduction catalyst.

[0032] The invention mixes activated carbon, ferrous chloride and nitrogen source to obtain a mixture.

[0033] In the present invention, the activated carbon is preferably bagasse activated carbon. Compared with other activated carbons, the present invention can further increase the loading of transition metals by adopting the bagasse activated carbon, thereby further improving the catalytic activity of the catalyst.

[0034] In the present invention, the preparation method of described bagasse gac preferably comprises the steps:

[0035] 1) mixing bagasse with an activator to obtain a mi...

Embodiment 1

[0061] A preparation method of an iron-nitrogen-carbon composite oxygen reduction catalyst comprises the following steps:

[0062] (1) After mixing bagasse gac, ferrous chloride and melamine, add ethanol solution and grind repeatedly until ethanol solution volatilizes completely, obtain mixture; Wherein, the mass ratio of described bagasse gac, ferrous chloride and melamine is 1: 4:4;

[0063] (2) Carbonizing the mixture obtained in the step (1) in a nitrogen atmosphere to obtain an iron-nitrogen-carbon composite oxygen reduction catalyst; wherein, the temperature of the carbonization is 700° C., and the time is 0.5 h;

[0064] The preparation method of described bagasse gac is as follows:

[0065] 1) Bagasse is mixed with KOH at a mass ratio of 1:6 after being pulverized by a pulverizer to obtain a mixed material;

[0066] 2) Heat the mixed material obtained in step 1) in a tube furnace at a heating rate of 10°C / min to 800°C for 1h activation, after activation, wash three t...

Embodiment 2

[0069] On the basis of Example 1, the carbonization temperature was replaced by 900° C., and other steps remained unchanged, to obtain an iron-nitrogen-carbon composite oxygen reduction catalyst.

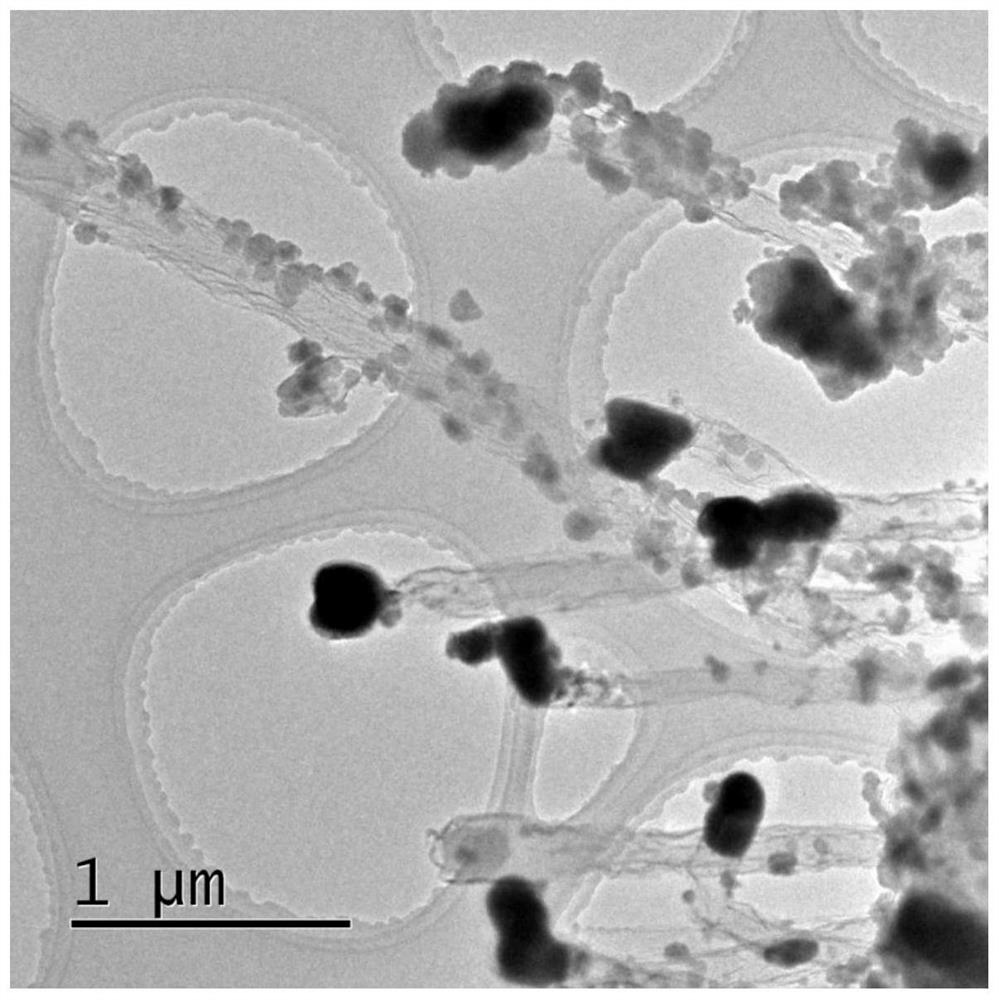

[0070] The SEM image of the iron-nitrogen-carbon composite oxygen reduction catalyst prepared in Example 2 is as follows figure 2 shown. From figure 2 It can be seen that the iron-nitrogen-carbon composite oxygen reduction catalyst presents a needle-like structure.

[0071] The TEM figure of the iron-nitrogen-carbon composite oxygen reduction catalyst prepared in Example 2 is as follows image 3 shown. From image 3 It can be seen that the black regions are iron and iron oxides, indicating that the preparation method provided by the present invention can well achieve uniform doping of transition metal iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com