Back contact heterojunction solar cell with by low laser damage as characteristic, and and manufacturing method thereof

A technology for solar cells and manufacturing methods, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as sensitivity to laser thermal effects, and achieve the effects of controlling laser damage, decreasing aperture ratio, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

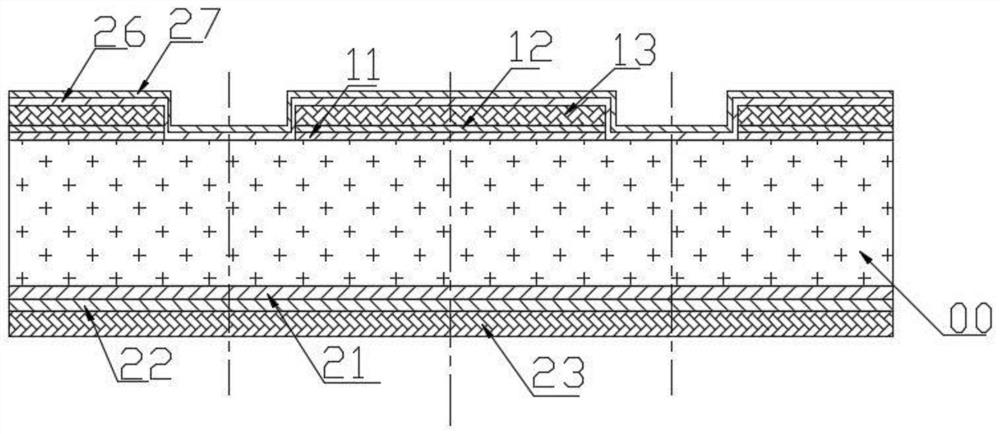

Image

Examples

preparation example Construction

[0068] The preparation process of the hydrogen-doped indium oxide thin film is to use pure indium oxide as a target material, then introduce hydrogen or water vapor into the process gas, and form a hydrogen-doped indium oxide thin film by physical vapor deposition.

[0069] The specific method of the step F is to print the anti-plating ink on the conductive layer obtained through the step E treatment.

[0070] The specific method of the step G is to prepare the first conductive region electrode and the second conductive region electrode by electroplating on the first conductive region and the second conductive region treated in the step C.

[0071] The specific process of step G is to form an electroplated copper grid electrode by immersion or horizontal brush contact, and form a protective tin of 100 nanometers to 5 microns on the copper grid electrode by covering it with chemical tin or electroplating tin. Floor.

[0072] The specific method of the step H is, after the trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com