Method for refining rare earth inclusions in super stainless steel

A stainless steel and inclusion technology, applied in the field of iron and steel metallurgy, can solve the problems of unclear state of calcium aluminate inclusions, unfavorable refinement of rare earth inclusions, high density of rare earth inclusions, etc., achieving favorable comprehensive performance and low rare earth processing cost , the effect of high yield of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

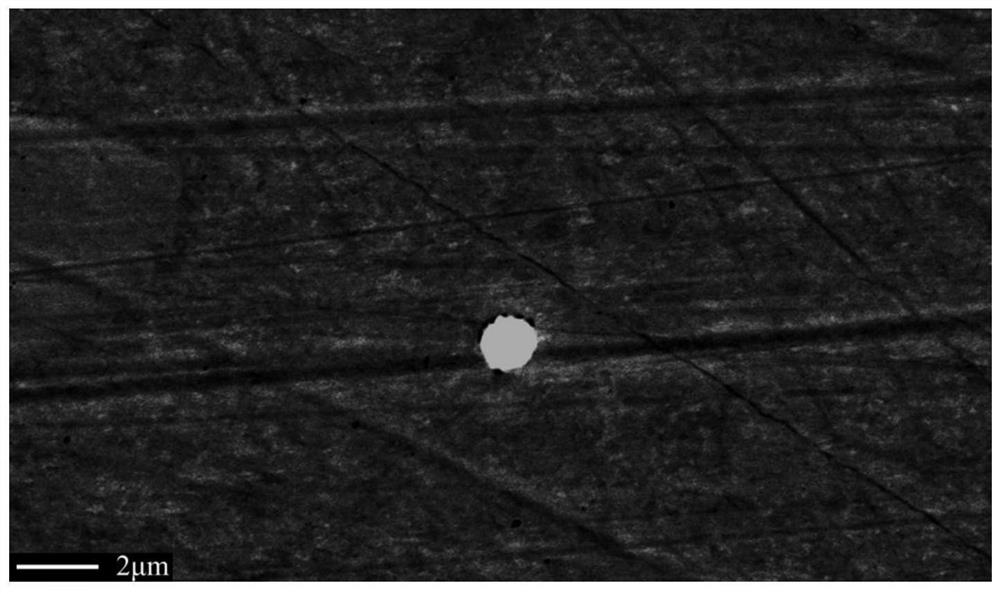

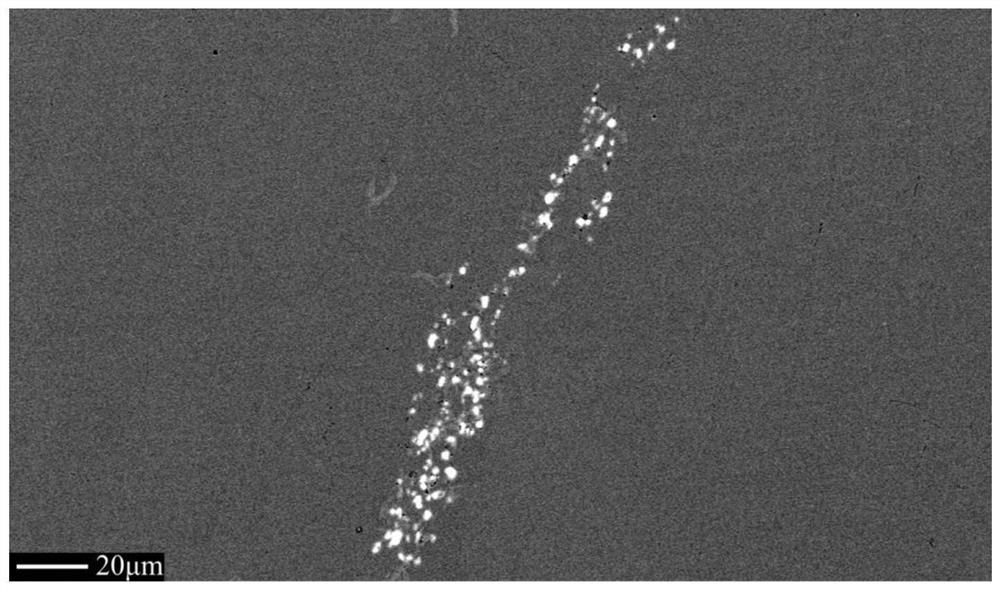

Image

Examples

Embodiment 1

[0088] The method for refining rare earth inclusions in super stainless steel provided in this embodiment consists of the following steps:

[0089] (1) Carry out primary refining of super stainless steel to be treated to obtain molten steel with slag;

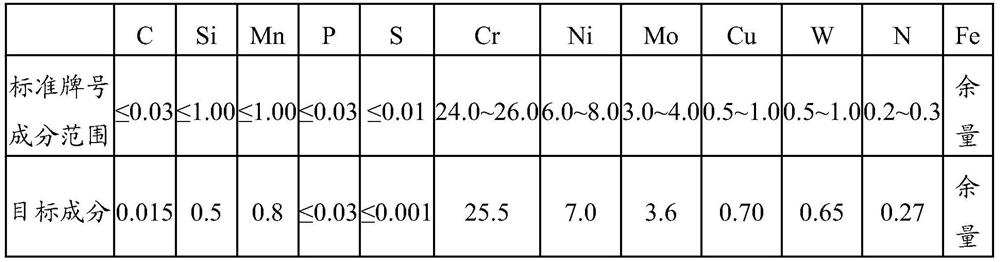

[0090] Among them, the super stainless steel to be treated is selected from S32760 super duplex stainless steel, and its composition is shown in Table 1; the quality of the super stainless steel to be treated is 45t; the initial refining is decarburization, chromium reduction and desulfurization according to conventional operations; The primary refining slag in molten steel with slag is 70% of the total amount of refining slag initially formed (i.e. 30% of slag removal); and the total oxygen content in molten steel with slag is 0.0072%, the sulfur content is 0.0011%, and the aluminum content is 0.008 %;

[0091] The composition (mass percentage, %) of the S32760 super duplex stainless steel that table 1 embodiment 1 step (1) u...

Embodiment 2

[0109] The method for refining rare earth inclusions in super stainless steel provided in this embodiment consists of the following steps:

[0110] (1) Carry out primary refining of super stainless steel to be treated to obtain molten steel with slag;

[0111] Among them, the super stainless steel to be treated is selected from 254SMO super austenitic stainless steel, and its composition is shown in Table 4; the quality of the super stainless steel to be treated is 35t; the initial refining is decarburization, chromium reduction and desulfurization carried out in sequence according to conventional operations; The primary refining slag in the molten steel with slag is 100% of the total amount of the initially formed refining slag; and the total oxygen content in the molten steel with slag is 0.0076%, the sulfur content is 0.0012%, and the aluminum content is 0.0069%;

[0112] The composition (mass percentage, %) of the 254SMO super austenitic stainless steel that table 4 embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com