Technology for making buffer with straw or stalk as main raw material

A technology of main raw materials and pads, which is applied in the field of production of cushioning pads and packaging materials, can solve problems such as work site and environmental pollution, limited molding thickness, rough surface, etc., and achieve low overall cost, high production efficiency, and easy degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

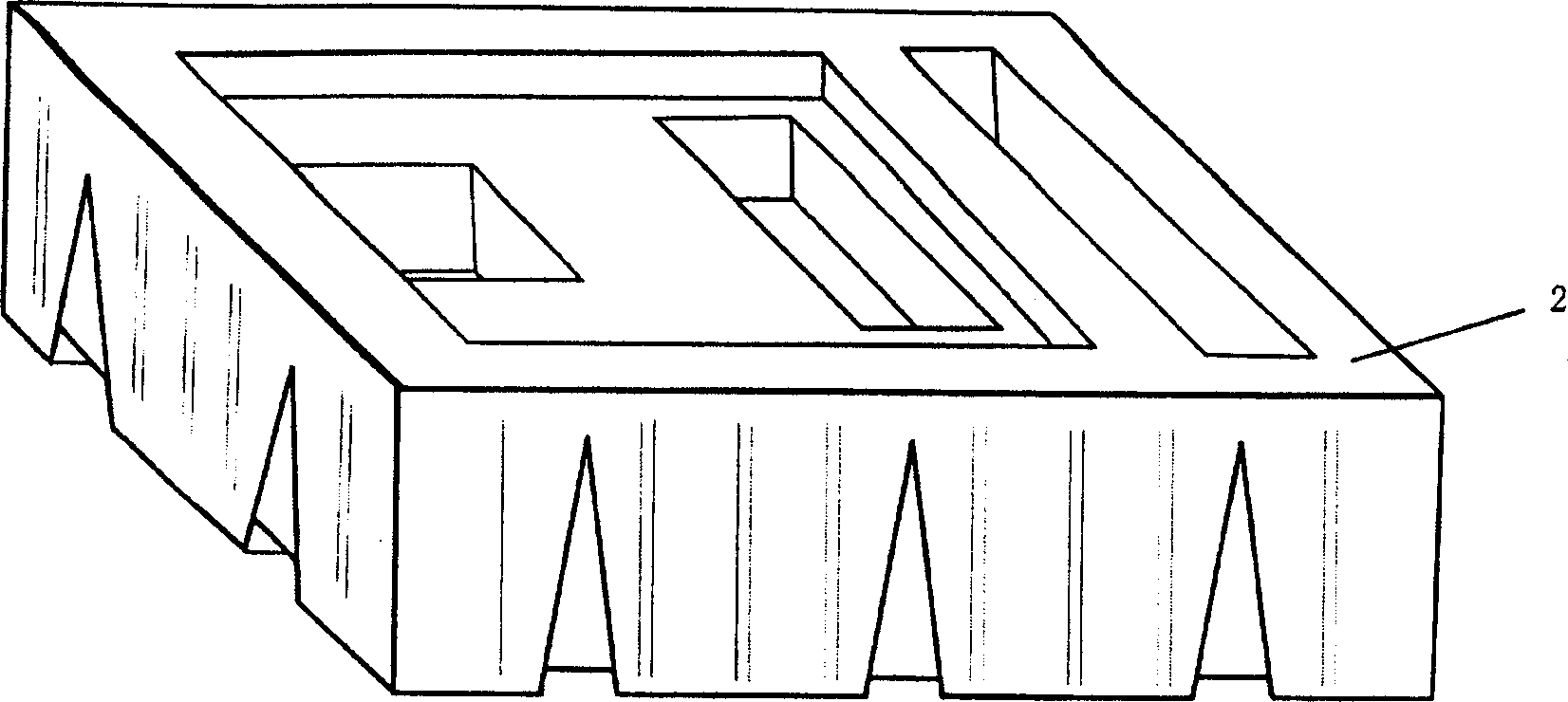

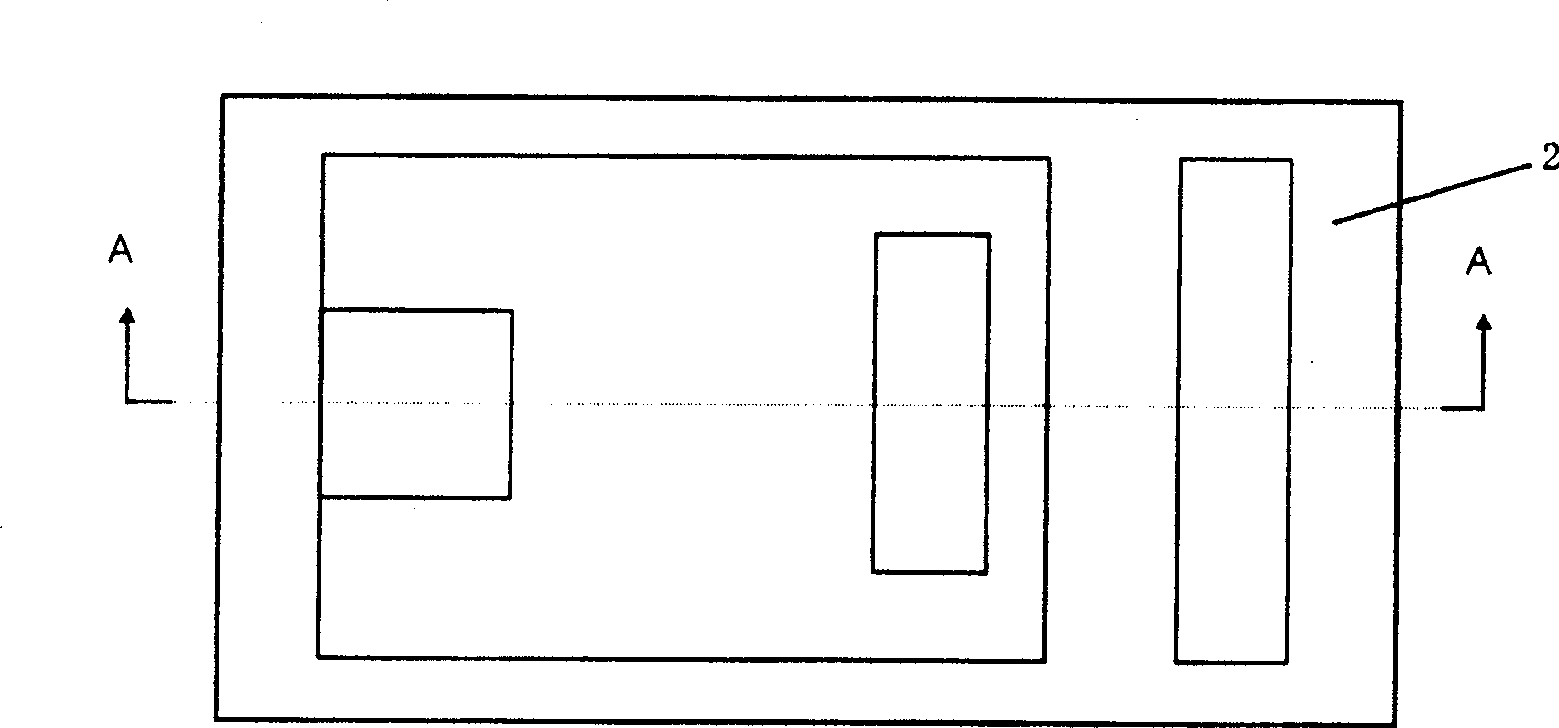

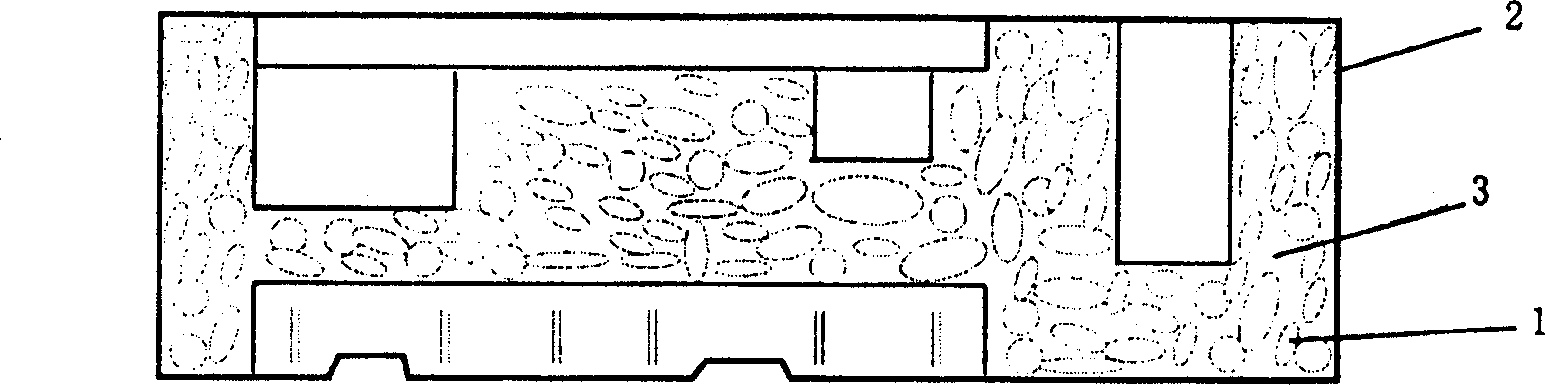

[0028] see figure 1 , figure 2 with image 3 . The production method of the cushion pad material is as follows:

[0029] (1) The crop stalks are pretreated for deworming and disinfection, and then crushed and processed into filler 1. The length of the stalks is generally controlled below 5cm;

[0030] (2) Use cardboard to make the upper and lower parts of the shell 2 of the gasket material. The shape of the shell can be processed into a hollow body with grooves or lattice structures in which two parts are connected according to needs. The wall thickness of the shell is about 3mm;

[0031] (3) Mix the prepared filler 1 with the VAE emulsion adhesive 3 evenly, put it into the lower half of the shell 2, and cure it at 45°C to 70°C;

[0032] (4) Cover the upper part of the housing 2, and seal the joint between the upper and lower parts, that is, the crop straw is used as the filler, fixed with the adhesive 3, and the outer shell is made of paper cushioning material.

Embodiment 2

[0034] see Figure 4 . The production method of the cushion pad material is as follows:

[0035] (1) The crop stalks are pretreated for deinsectization and disinfection, and then crushed and processed into filler 1. The length of the stalks is generally controlled below 5 cmm;

[0036] (2) Make the upper and lower parts of the shell 2 of the cushion material with cardboard, and the shell wall thickness is about 3mm;

[0037] (3) Melt the PET hot-melt adhesive at 80°C to 90°C, mix the prepared filler 1 and the hot-melt agent 3 evenly, put them into the lower half of the shell 2, and solidify at room temperature;

[0038] (4) Cover the upper half of the housing, and seal the joint between the upper and lower parts, that is, the crop straws are used as fillers, fixed with adhesive 3, and the outer shell is made of paper cushioning material.

Embodiment 3

[0040] see figure 1 , figure 2 with image 3 . The production method of the cushion pad material is as follows:

[0041] (1) Treat the corn stalks first, remove the leaves, roots and shoots, and take out some straw cores in the crusher, of which the length is 10cm 15%.

[0042] (2) Polyethylene (melt index 2.0g / 10min, density 0.915g / cm 3 ) to make the shell 2 of the thin-walled packaging container, which has a volume of 12×35×5 cm and a wall thickness of about 0.01 cm. The housing 2 can be made into an integral container, leaving only the feed inlet for loading crop fillers.

[0043] (3) Take 13.9Kg of urea-formaldehyde glue with a content of 65%, add it to the foaming machine, and the rotating speed is 300r / min, and add 2Kg of glycerin, 3Kg of soybean powder, 4Kg of 10% polyvinyl alcohol solution, and 0.4Kg of powder (water-soluble in advance) Open), foam for 5 minutes, add 0.15Kg of ammonium chloride (dissolved with a little water in advance), and then foam for 5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com