Triple bathtub water faucet and processing method

A technology for faucets and bathtubs, applied in the field of sanitary ware, can solve the problems of rough surface of the faucet body, consumption of large metal materials, occurrence of blisters and pores, etc., and achieve the effects of smooth surface, low energy consumption and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

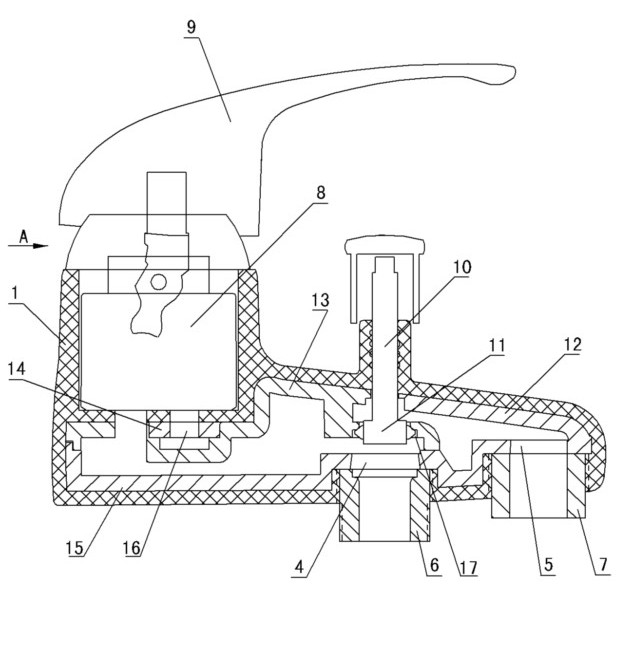

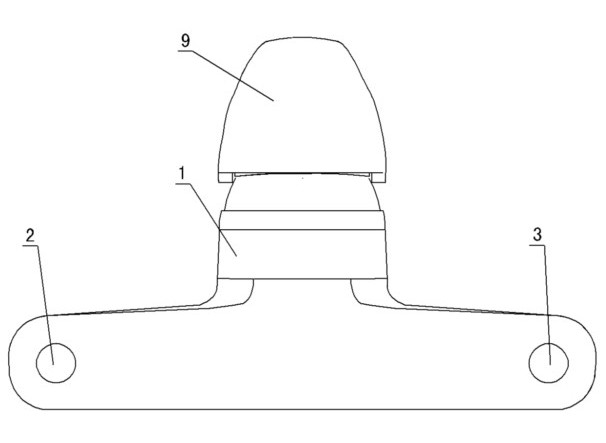

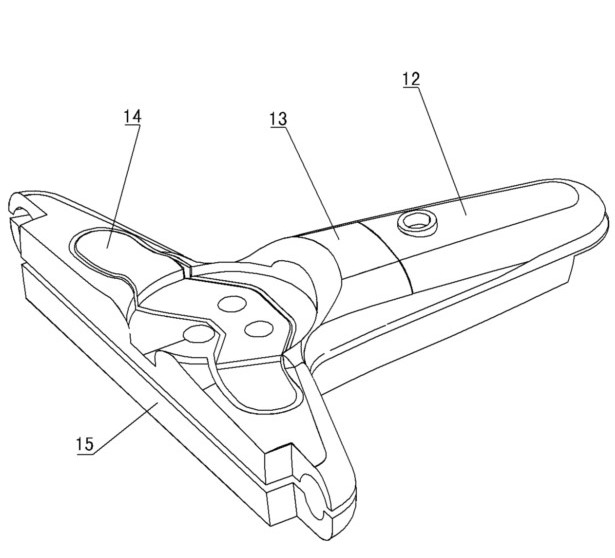

[0016] The present invention relates to a triple bathtub faucet, such as Figure 1-Figure 3 As shown, it includes a faucet body 1 injection-molded by plastic material. The rear part of the body 1 is formed with a cold water interface 2 and a hot water inlet 3. The cold and hot water inlets are respectively connected to the cold and hot water pipes. The front part of the body 1 is installed under the Shower connector 6 and water drop interface 7, the top of shower connector 6 is equipped with valve rod 10, and the head of valve rod 10 is shaped on valve head 11, and spool 8 is installed in the body 1, is provided with waterway in the body, is installed on the spool 8. There is a handle 9, and the water channel is connected to each inlet and outlet. It is characterized in that the water channel includes a water channel front cover 12, a water channel main body upper cover 13, a cold and hot water inlet upper cover 14, and a water channel main body lower cover 15. Composed of ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com