Method for preparing solid aldehyde cloth through two-step method

A solid-state, aldehyde cloth technology, applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of weak killing effect on bacterial spores, poor stability of solid aldehyde, low content of aldehyde groups, etc., to meet the stability requirements, Avoid hardening and brittleness and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

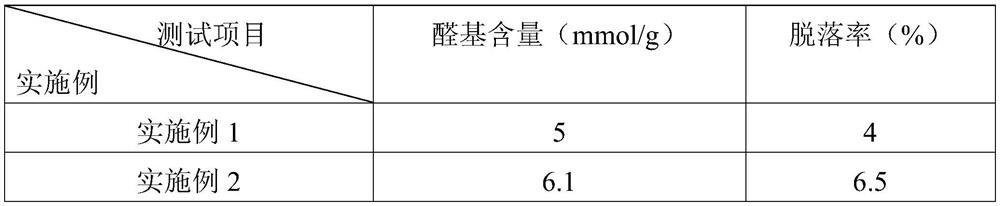

Examples

Embodiment 1

[0028] A two-step method for preparing solid aldehyde cloth, the specific steps of the method are as follows:

[0029] (1) Add 1g of ethylene glycol diglycidyl ether to 100ml of polyvinylamine aqueous solution with a mass fraction of 5%, mix well to obtain a mixed solution; then soak 5g of spunlace non-woven fabric in the mixed solution for 5min, take it out and roll Extrude and dehydrate the car to keep the liquid-carrying rate at 100%; heat and solidify in an oven at 70°C to obtain a polyvinylamine modified spunlace nonwoven fabric, and the mass of the spunlace nonwoven fabric is increased to 8g, and the sample is tested at this time The liquid pick-up rate was 20%.

[0030] (2) Soak 8g of polyvinylamine modified spunlace nonwoven fabric in 65g of 5% glutaraldehyde aqueous solution for 5min, the aldehyde group in glutaraldehyde and the amine in polyvinylamine modified spunlace nonwoven fabric The base molar ratio was 2:1, and the solution temperature was kept at 10°C. Afte...

Embodiment 2

[0032] A two-step method for preparing solid aldehyde cloth, the specific steps of the method are as follows:

[0033] (1) Add 5g of polyethylene glycol diglycidyl ether to 100ml of triethylenetetramine aqueous solution with a mass fraction of 20%, mix well to obtain a mixed solution; then soak 2g of apocynum in the above solution for 10min, take it out and centrifuge Dehydration, the liquid-carrying rate is 300%; it is placed in an oven at 100° C. for heating and curing to obtain triethylenetetramine-modified apocynum, and the mass of the apocynum is increased to 5 g, and the liquid-carrying rate is 10% at this time for sampling test.

[0034] (2) 5g triethylenetetramine modified apocynum is soaked in 30g mass fraction and is 20min in the succinic dialdehyde solution of 50%, and the aldehyde group in the succinic dialdehyde and the amine group molar ratio in the triethylenetetramine are 5:1, Keep the solution temperature at 20 °C. After taking it out, rinse it with distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com