High-strength MPP cable protection pipe

A cable protection tube, high-strength technology, applied in the field of high-strength MPP cable protection tube, can solve the problems of low heat resistance, easy to break, low strength, etc., to improve ring stiffness and impact resistance, improve bending strength, Effect of increasing sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

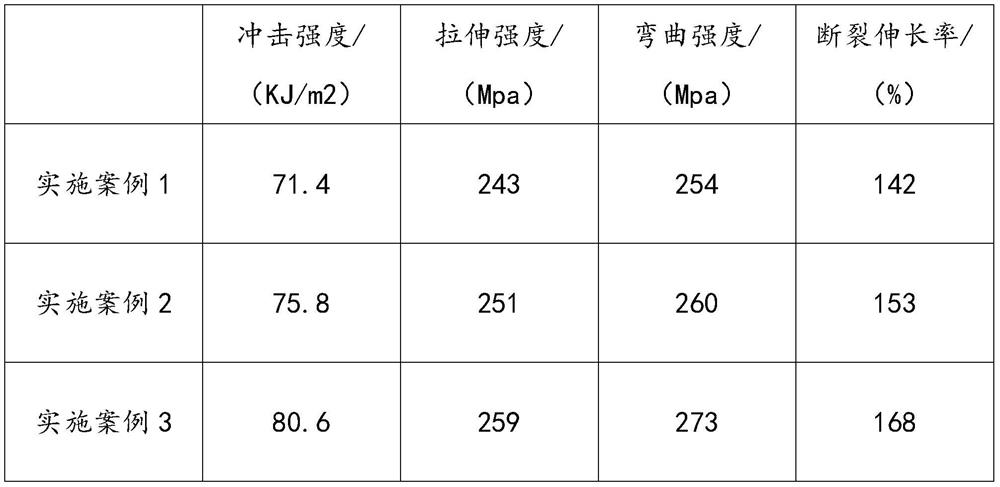

Examples

preparation example Construction

[0038] Further, the preparation method of the composite base material comprises the following steps:

[0039] S11, Stir and disperse montmorillonite in a saturated sodium chloride solution at 50°C-65°C, heat to boiling, cool down to room temperature in an ice bath, then add deionized water to stir, then ultrasonically disperse for 1 hour, add octadecyl Trimethylammonium chloride, reacted at 85°C for 1.5h to 2h, stood still for 10h after the reaction was completed, centrifuged, washed, dried, and then ground to obtain modified montmorillonite;

[0040] S12. Stir and disperse the modified montmorillonite in the acetone solution, add maleic anhydride grafted polypropylene, and mix evenly with magnetic stirring, then vacuum remove the acetone at room temperature to obtain the mixed material A, and send the mixed material A into the screw extruder In the machine, melt blending and extruding at 150°C to obtain the mixed material B, and send the hydroxybenzoic acid, styrene and the m...

Embodiment example 1

[0051] Weigh 100 parts of montmorillonite, 150 parts of sodium chloride solution, 80 parts of acetone solution, 30 parts of maleic anhydride grafted polypropylene, 90 parts of nano-zirconia, 35 parts of toluene, octadecyltrimethylammonium chloride 40 parts, 15 parts of hydroxybenzoic acid, 30 parts of styrene and 75 parts of oleic acid, montmorillonite were stirred and dispersed in a saturated sodium chloride solution at 65 °C, heated to boiling, cooled to room temperature in an ice bath, and then added deionized Stir with water, then ultrasonically disperse for 1h, add octadecyltrimethylammonium chloride, react at 85°C for 2h, let stand for 10h after the reaction is completed, centrifuge, wash, dry and grind to obtain modified montmorillonite , Stir and disperse the modified montmorillonite in the acetone solution, add maleic anhydride grafted polypropylene, and mix evenly with magnetic stirring, remove the acetone in vacuum at room temperature to obtain the mixed material A, ...

Embodiment example 2

[0057]Weigh 100 parts of montmorillonite, 150 parts of sodium chloride solution, 80 parts of acetone solution, 30 parts of maleic anhydride grafted polypropylene, 90 parts of nano-zirconia, 35 parts of toluene, octadecyltrimethylammonium chloride 40 parts, 15 parts of hydroxybenzoic acid, 30 parts of styrene and 75 parts of oleic acid, montmorillonite were stirred and dispersed in a saturated sodium chloride solution at 65 °C, heated to boiling, cooled to room temperature in an ice bath, and then added deionized Stir with water, then ultrasonically disperse for 1h, add octadecyltrimethylammonium chloride, react at 85°C for 2h, let stand for 10h after the reaction is completed, centrifuge, wash, dry and grind to obtain modified montmorillonite , Stir and disperse the modified montmorillonite in the acetone solution, add maleic anhydride grafted polypropylene, and mix evenly with magnetic stirring, remove the acetone in vacuum at room temperature to obtain the mixed material A, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com