High-performance special heat insulation piece for aero-engine exhaust nozzle

A technology for aero-engines and heat insulation parts, which is applied to machines/engines, applications, household appliances, etc., can solve the problems of expensive porous ceramic fiber materials, and achieve excellent processability, high safety performance, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

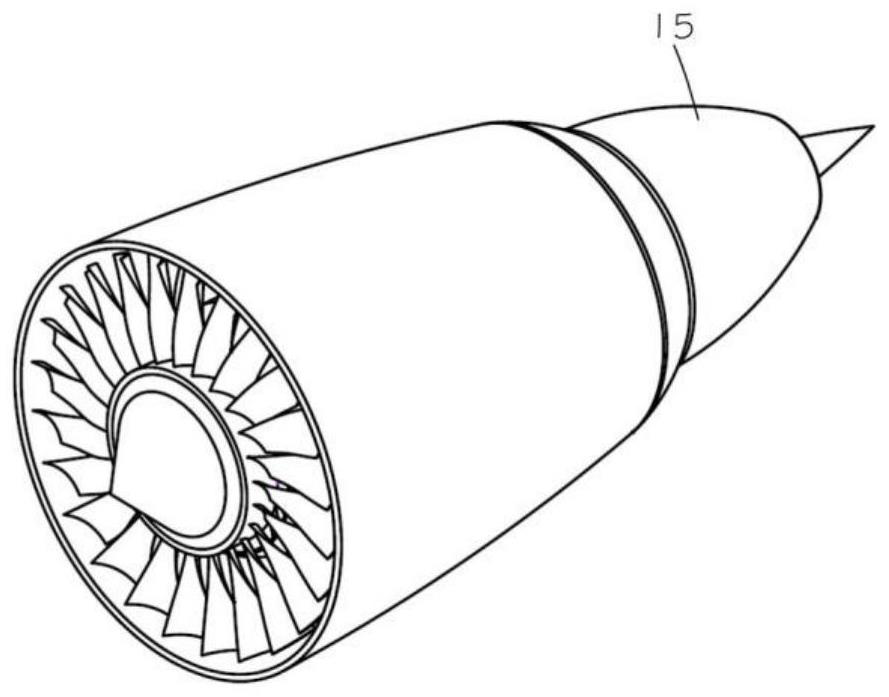

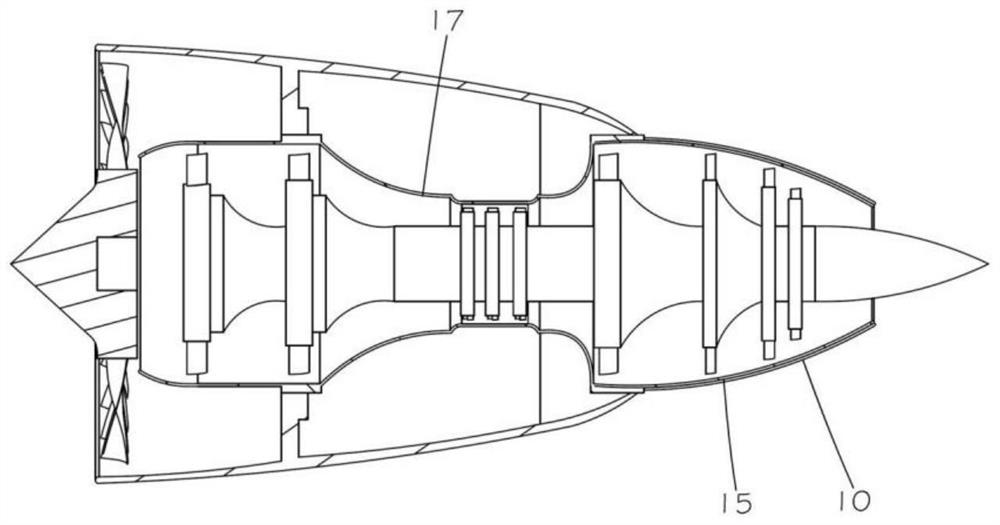

[0035] Such as Figure 1 to Figure 5 The high-performance special thermal insulation piece 10 for the aero-engine tail nozzle of the present invention as shown includes a first stainless steel sheet metal layer 11, a thermal insulation layer 12 and a second stainless steel sheet metal layer 13, and the thermal insulation layer 12 is located at the first Between the first stainless steel sheet metal layer 11 and the second stainless steel sheet metal layer 13 . The first stainless steel sheet metal layer 11 and the second stainless steel sheet metal layer 13 not only have a certain rigidity, but also have good ductility, which can make the heat insulating part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com