Zirconia ceramic injection molding catalytic degreasing feed as well as preparation method and application thereof

A zirconia ceramic and injection molding technology, which is applied in the field of zirconia ceramic injection molding catalytic degreasing feed and its preparation, can solve the problems of easy deformation of ceramic green bodies, and achieve the effects of good shape, avoiding agglomeration, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

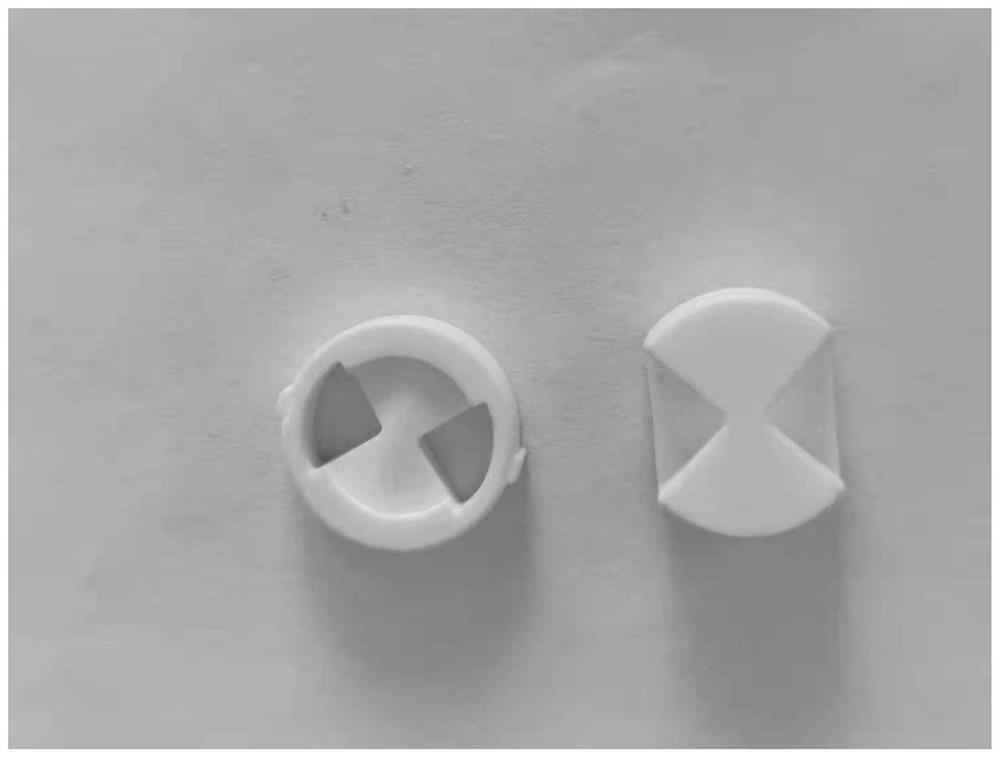

Image

Examples

Embodiment 1

[0032] The raw material composition of zirconia ceramic injection molding catalytic degreasing feed is as follows: the mass ratio of zirconia powder to binder is 81:19; in the binder, polyoxymethylene, high-density polyethylene, microcrystalline wax, phthalic acid The weight ratio of esters is 72:18:6:4.

[0033] The preparation method and application method are:

[0034] (1) Internal mixing: Dry the zirconia powder at 100°C for 6 hours for pretreatment, set the temperature of the internal mixer at 170°C, and the stirring speed at 10r / min, add polyoxymethylene and high-density polyethylene, and mix 10min, then add zirconia powder and microcrystalline wax accounting for 2 / 3 of the total mass of zirconia powder, knead for 5min, add the remaining zirconia powder, knead for 15min, then add phthalate, mix Refining for 90 minutes to obtain the mixed lump feed;

[0035] (2) Granulation: Put the mixed lump feed into the granulator, set the temperature at 140°C, the extrusion speed a...

Embodiment 2

[0039] The raw material composition of zirconia ceramic injection molding alcohol solvent degreasing feed is as follows: the ratio of zirconia powder to binder is 83:17, and the binder includes polyoxymethylene, high-density polyethylene, ethylene vinyl acetate copolymer, phthalate The weight ratio of formic acid diester is 74:17:7:2.

[0040] The preparation method and application method are:

[0041] (1) Internal mixing: Dry the zirconia powder at 105°C for 8 hours for pretreatment, set the temperature of the internal mixer at 175°C, and the stirring speed at 15r / min, add polyoxymethylene and high-density polyethylene, and mix 8 minutes, then add zirconia powder and ethylene vinyl acetate copolymer accounting for 3 / 4 of the total mass of zirconia powder, knead for 8 minutes, add the remaining zirconia powder, knead for 20 minutes, and then add phthalic acid diester , kneading for 100min, to obtain a good mixed feed;

[0042] (2) Granulation: Put the mixed lump feed into th...

Embodiment 3

[0046] The raw material composition of zirconia ceramic injection molding alcohol solvent degreasing feed is: the ratio of zirconia powder to binder is 84:16, polyoxymethylene, polyvinyl alcohol, microcrystalline wax, dimethyl phthalate in the binder The weight ratio of esters is 75:16:6:3.

[0047] The preparation method and application method are:

[0048](1) Internal mixing: Dry the zirconia powder at 110°C for 8 hours for pretreatment, set the temperature of the internal mixer at 165°C, and the stirring speed at 10r / min, add polyoxymethylene and polyvinyl alcohol, and mix for 10 minutes , then add zirconia powder and microcrystalline wax accounting for 2 / 3 of the total mass of zirconia powder, knead for 10 minutes, add the remaining zirconia powder, knead for 20 minutes, then add dimethyl phthalate, mix Refining for 120min to obtain the mixed lump feed;

[0049] (2) Granulation: Put the mixed lump feed into the granulator, set the temperature at 145°C, the extrusion spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com