Antibacterial and antiviral graphene and nano mirror aluminum composite material as well as preparation method and application thereof

A technology of aluminum composite materials and graphene nanosheets, which is applied in the direction of graphene, chemical instruments and methods, alumina/hydroxide preparation, etc., can solve the problems of increasing the complexity of fabric preparation, manufacturing costs, and threats to use safety , to achieve efficient self-heating, not easy to reunite, and improve the effect of penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of antibacterial and antiviral graphene and nano-mirror aluminum composite material, comprising the following steps:

[0031] S1. Dissolving the organic ligand in an organic solvent, then adding graphene nanosheets, and ultrasonically dispersing evenly to obtain an organic ligand solution.

[0032] The organic ligand is one or more of polycarboxylic acids or imidazoles, preferably polycarboxylic acids, such as terephthalic acid, isophthalic acid, trimesic acid, and 1,4-dinaphthalic acid; The organic solvent is one or more of ethanol, diethylformamide, dimethylformamide, and N-methylpyrrolidone. In this step, the polycarboxylic acid or imidazole organic ligands are adsorbed on the surface of the graphene nanosheets, which is helpful for the exfoliation and dispersion of the graphene nanosheets and is not easy to agglomerate. When it is preferably a polycarboxylic acid, it is helpful for the formation of nano-alumina in the sub...

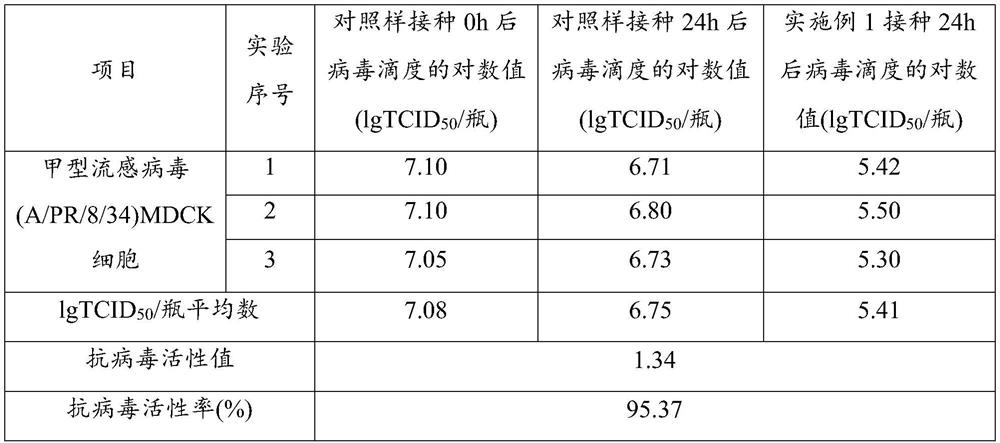

Embodiment 1

[0045] An antibacterial and antiviral graphene and nano-mirror aluminum composite material, the preparation method comprising the following steps:

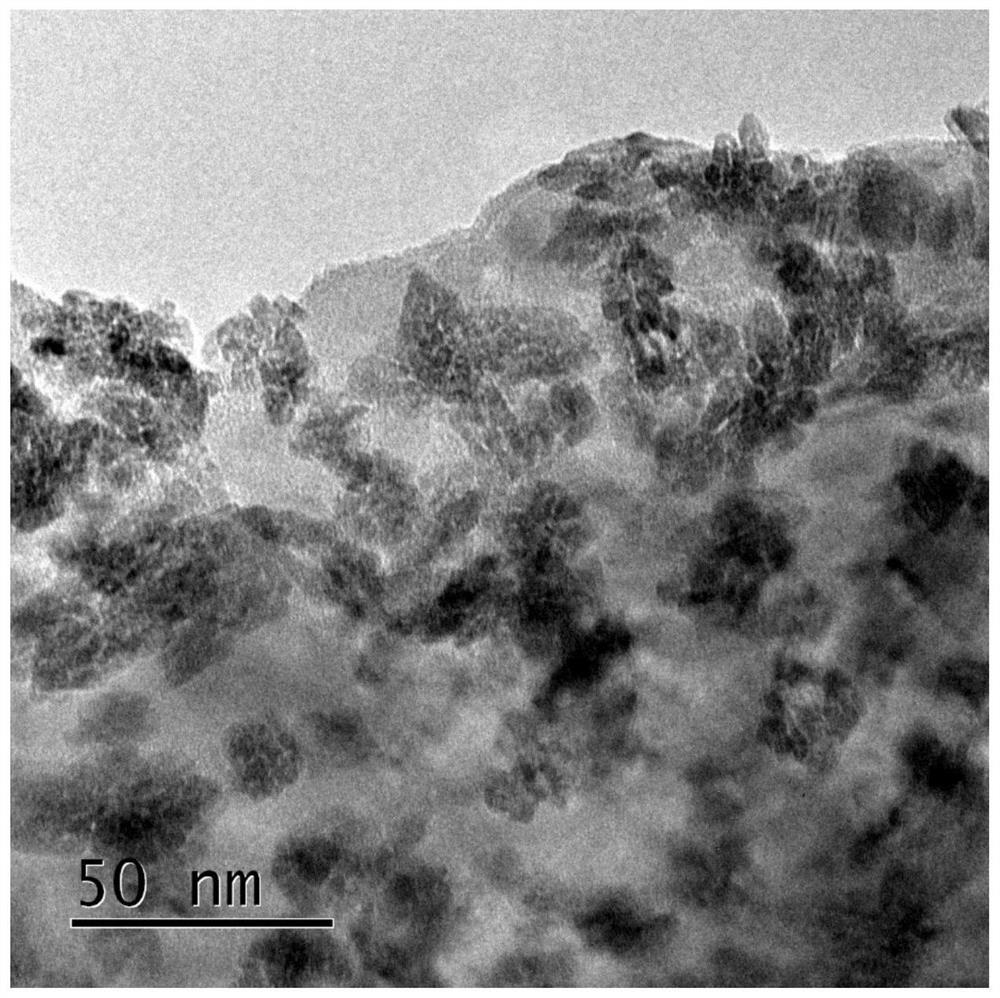

[0046] S1. terephthalic acid is dissolved in N-methylpyrrolidone (concentration is 30mmol / mL), then add graphene nanosheets (lateral size is about 300nm, thickness is about 8nm, terephthalic acid and graphene nanosheets The mass ratio is 1:5), and the ultrasonic dispersion is uniform to obtain an organic ligand solution;

[0047] S2. According to the molar ratio of the inorganic aluminum salt and the organic ligand being 1.5:1, add aluminum nitrate to the organic ligand solution obtained in step S1, react in a reactor at 150° C. for 20 h, then centrifuge and wash , dry to obtain Al-MOFs / graphene composite material;

[0048] S3. The Al-MOFs / graphene composite material obtained in step S2 is heated up to 850° C. at a heating rate of 2° C. / min in a mixed gas atmosphere with a volume ratio of 1%:99.9% oxygen and an inert gas, Calcin...

Embodiment 2-6

[0059] Embodiment 2-6 antibacterial and antiviral graphene and nano-mirror aluminum composite material, compared with embodiment 1, the difference is that graphene lateral dimension and aperture are as shown in table 1, other is approximately the same as embodiment 1, in This will not be repeated here.

[0060] Preparation conditions and performance test results of table 1 embodiment 2-6

[0061]

[0062] It can be seen from Table 1 that with the reduction of the lateral size of graphene nanosheets, the far-infrared emission performance gradually increases and remains basically unchanged, indicating that the selection of smaller-sized graphene nanosheets and nano-mirror aluminum oxide porous carbon composites, It is more conducive to improving the far-infrared self-heating performance of the fabric. When porous graphene nanosheets are selected, the far-infrared self-heating performance and air permeability of the fabric are improved, and the improvement rate of small-sized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com