Ozone oxidation catalyst for wastewater treatment and application method thereof

An ozone oxidation and wastewater treatment technology, applied in the field of water treatment, can solve the problems of poor stability, low catalytic efficiency, poor hydrodynamic performance, etc., and achieve the effects of high stability, large specific surface area, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A wastewater treatment ozone oxidation catalyst has the following characteristics:

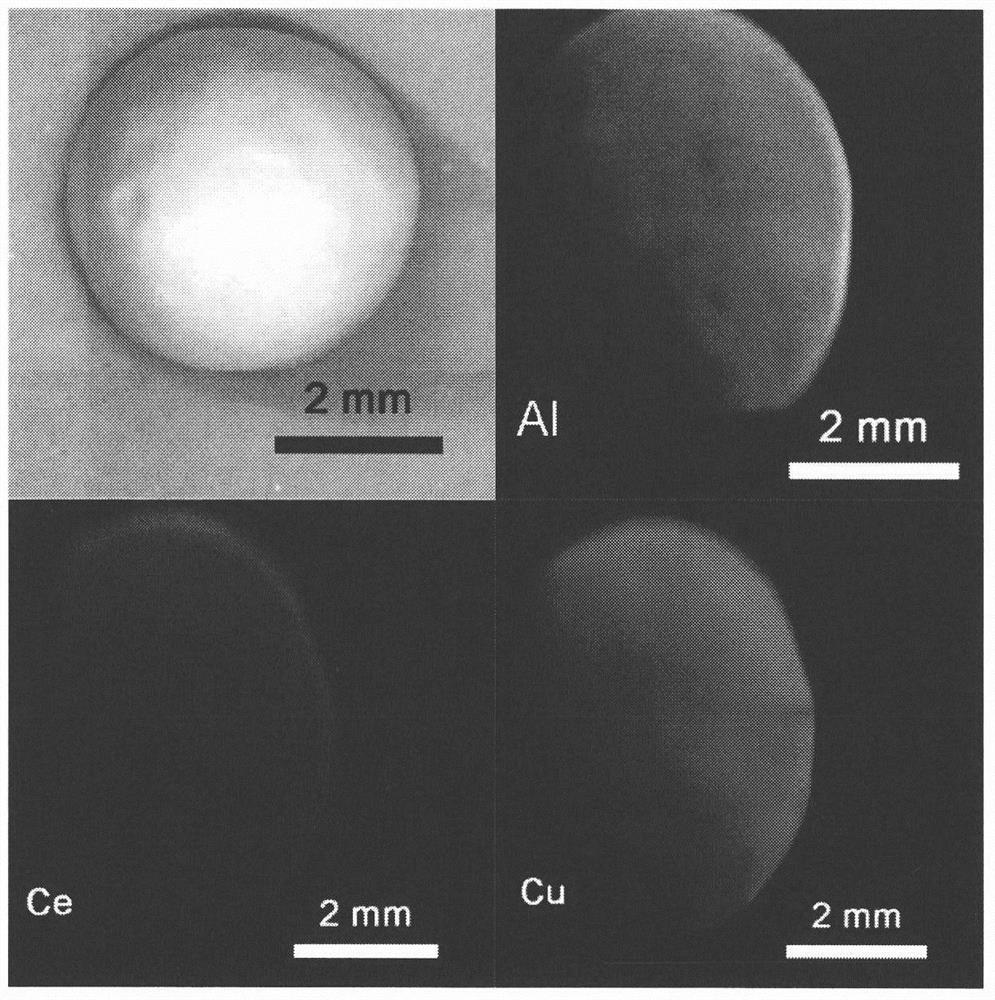

[0048] (1) The catalyst contains aluminum, copper, cerium and oxygen, the mass fraction of aluminum is 43%, the mass fraction of copper is 1.4%, the mass fraction of cerium is 1.6%, and the mass fraction of oxygen is 39% %, its X-ray fluorescence imaging (see figure 1 ) shows that the above-mentioned metal elements are uniformly distributed throughout the catalyst sphere;

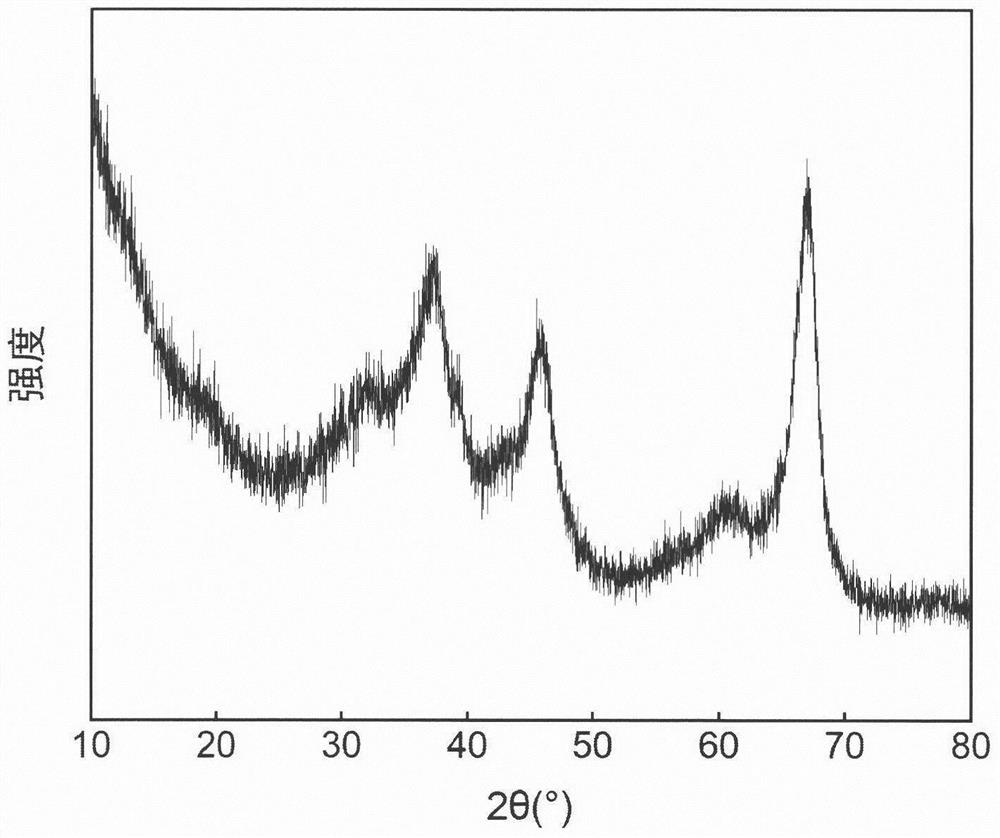

[0049] (2) The catalyst is composed of composite metal oxides containing aluminum, copper, and cerium, and all components except alumina include γ-Al 2 o 3 Except crystal form, other components are amorphous, and described catalyst X-ray diffraction spectrum (see figure 2 ) in addition to γ-Al 2 o 3 Does not contain other crystalline substance diffraction peaks;

[0050] (3) The morphology of the catalyst is a mesoporous millimeter sphere, and the particle size distribution is in the range of 3 to 5 mm. It is ...

Embodiment 2

[0058] A wastewater treatment ozone oxidation catalyst has the following characteristics:

[0059] (1) The catalyst contains aluminum, copper, cerium and oxygen, the mass fraction of aluminum is 46%, the mass fraction of copper is 2.3%, the mass fraction of cerium is 1.2%, and the mass fraction of oxygen is 42% %;

[0060] (2) The catalyst is composed of composite metal oxides containing aluminum, copper, and cerium, and all components except alumina include γ-Al 2 o 3 Except for the crystal form, other components are amorphous, except for γ-Al in the X-ray diffraction spectrum of the catalyst 2 o 3 Does not contain other crystalline substance diffraction peaks;

[0061] (3) The morphology of the catalyst is a mesoporous millimeter sphere, and the particle size distribution is in the range of 3 to 5 mm. It is tested by the method specified in "HG / T 3927-2020 Industrial Activated Alumina". The compressive strength is 150N / particle, and the tap density is 0.76g / cm 3 , the ...

Embodiment 3

[0073] The catalyst described in embodiment 1 also has the following features or beneficial effects:

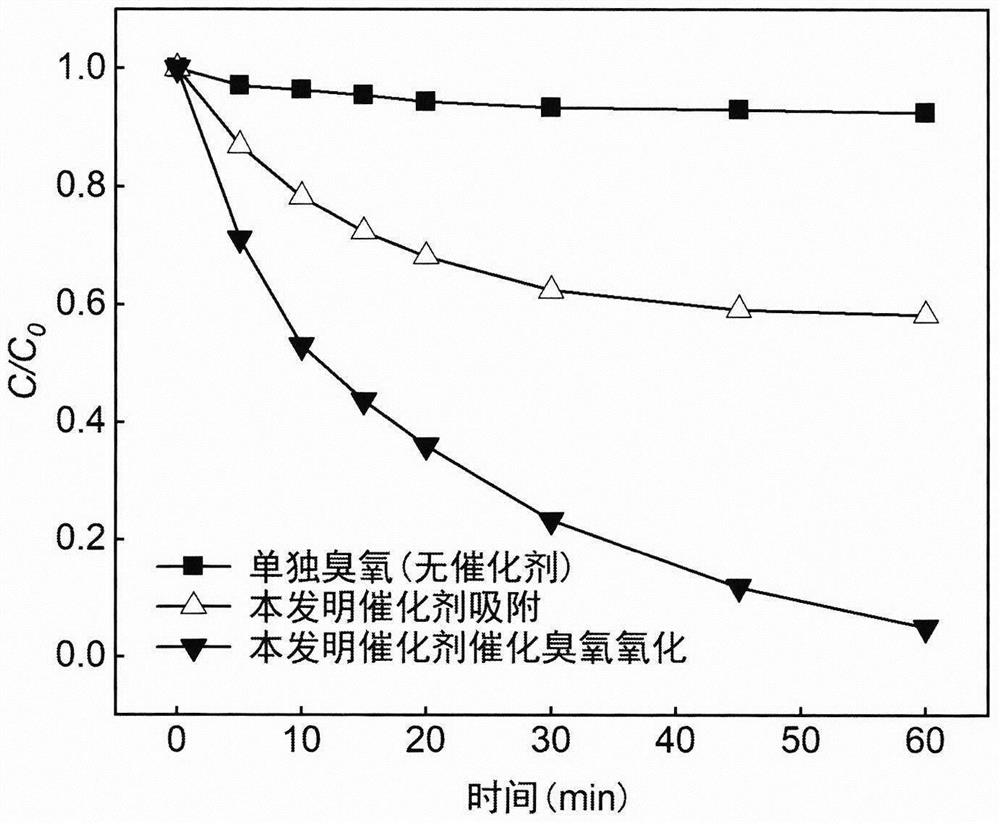

[0074] (1) The catalyst is active in catalytic ozonation degradation for oxalic acid (see Figure 4 ), the catalyst contacts with the oxalic acid solution E1 with a solid-to-liquid ratio of 50g / L and adds 0.8mol O to the solid-liquid mixture with every liter of liquid 3 The rate of removal of oxalic acid is 99% after feeding the gas F containing ozone at the dosage of / min for 30 minutes, and the removal rate of oxalic acid is 22% under the ozone oxidation treatment under the same conditions without a catalyst. Increased by 77 percentage points, the oxalic acid solution E1 is an aqueous solution of oxalic acid, the concentration of oxalic acid is 1.1mol / L, and the pH of the solution is 7.0, and the ozone-containing gas F is a mixed gas of ozone and oxygen; When the duration of ozone gas F is extended to 60min, the removal rate of oxalic acid is 99% when the catalyst is added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com