Cheese toppings for baked snacks suitable for pre-bake application

A technology for cheese and baking, which is applied in baked food, baking, application, etc. It can solve the problems that snack products cannot provide multiple textures and appearances, and achieve unique appearance and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Cheese Slurry Solid Consistency

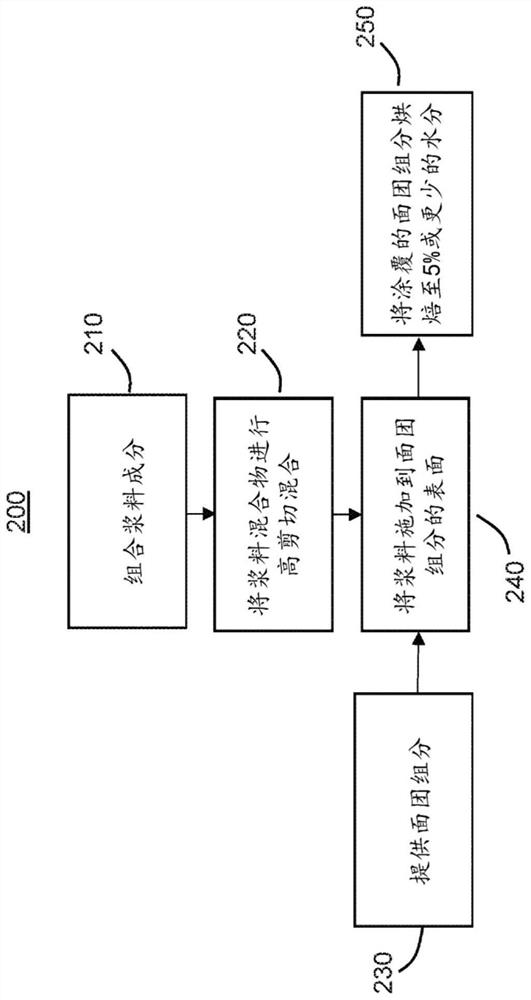

[0079] In the benchtop, a cheese slurry composition was formed by combining oil, lecithin, water, cheddar cheese powder solids, and pregelatinized starch in a spackl mixer in the amounts listed below in Table 5, and then Mixed in a high shear mixer (OLSA, Breddo Likwifier).

[0080] table 5

[0081] Element dry weight basis% formula% pregelatinized starch 2.48 2.64 water 0.00 0.26 lactic acid 0.01 0.014 vegetable oil 53.96 52.77 Lecithin 0.72 0.7 cheese powder 42.82 43.62

[0082] The slurry also included 1.250% sodium and 7.5% protein to assess slurry solids consistency. The slurry was transferred to a slurry application unit equipped with a dispersion drum (General Oil Equipment, Variable Profile Liquid Spray System).

[0083] Cheese slurry solids consistency provided by the slurry application unit was evaluated by analysis of sodium and protein concentratio...

Embodiment 2

[0088] Example 2: Consistency of slurry coverage

[0089] The slurry from Example 1 was collected on the tray below the applicator and the slurry weight was recorded. Samples were collected over a one hour period. As shown in Table 7, the slurry delivered weight was consistent over the one hour test period with a standard deviation of 2% to 6% in delivered weight depending on the spray pattern setting.

[0090] Table 7

[0091]

[0092]

Embodiment 3

[0093] Embodiment 3: the variation of the viscosity of cheese slurry with temperature

[0094] According to the recipe provided in Table 5 above, a cheese slurry composition with 40% cheese solids was prepared. A 25 ml sample of the cheese slurry was stirred at 160 rpm and after equilibrating at 35°C (95°F), 46°C (115°F) and 56°C (133°F) the viscosity was tested using a rapid viscosity analyzer (Perten, model 4500) . Viscosity results reported in cP are provided in Table 8 below and Figure 8 middle. A silicone viscosity standard solution of 5,000cP (25°C) was also tested for reference.

[0095] Table 8

[0096]

[0097] These data illustrate that increasing the temperature of a cheese slurry with 40% cheese solids to a temperature of as much as 133°F reduces the slurry viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com