Pre-melting type crystallizer casting powder for non-oriented silicon steel and preparation method thereof

A technology of mold flux and oriented silicon steel, applied in the field of metallurgy, can solve the problems of no application of non-oriented silicon steel, high thermal resistance of non-oriented silicon steel, increase of thermal resistance of steel, etc., so as to reduce heat transfer speed, inhibit SiO2 reaction, reduce The effect of crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This example provides a pre-melted mold powder for non-oriented silicon steel. The raw materials include: 35 parts of pre-melted calcium silicate, 18 parts of quartz powder, 11 parts of albite, 3 parts of soda ash, sodium fluoride + ice crystals 11 parts of stone compound, 9 parts of 95 fluorite, 6 parts of lithium carbonate, 4 parts of manganese carbonate, 2 parts of mixed carbon, and the balance is dextrin. Separation, cooling, testing, and packaging to obtain mold powder for non-oriented silicon steel.

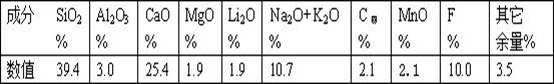

[0022] The physical and chemical indicators of mold slag for non-oriented silicon steel pre-melting mold are as follows:

[0023] Table 1

[0024]

[0025] Table 2

[0026]

Embodiment 2

[0028] This example provides a pre-melted mold powder for non-oriented silicon steel. The raw materials include: 34 parts of pre-melted calcium silicate, 19 parts of quartz powder, 9 parts of albite, 5 parts of soda ash, sodium fluoride + ice crystals 9 parts of stone compound, 10 parts of 95 fluorite, 4 parts of lithium carbonate, 5 parts of manganese carbonate, 3 parts of mixed carbon, and the balance is dextrin. Separation, cooling, testing, and packaging to obtain premelted mold powder for non-oriented silicon steel.

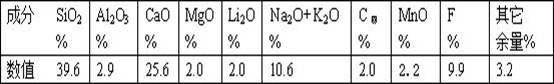

[0029] table 3

[0030]

[0031] Table 4

[0032]

Embodiment 3

[0034]This example provides a pre-melted mold powder for non-oriented silicon steel. The raw materials include: 33 parts of pre-melted calcium silicate, 19 parts of quartz powder, 10 parts of albite, 4 parts of soda ash, sodium fluoride + ice crystals 10 parts of stone compound, 10 parts of 95 fluorite, 5 parts of lithium carbonate, 5 parts of manganese carbonate, 2.5 parts of mixed carbon, and the balance is dextrin. Separation, cooling, testing, and packaging to obtain premelted mold powder for non-oriented silicon steel.

[0035] table 5

[0036]

[0037] Table 6

[0038]

[0039] In summary, the premelted mold mold powder for non-oriented silicon steel prepared by the present invention is well applied in a steel factory, the thickness of the slag layer is 8-12mm, the consumption is 0.6kg / t, no agglomeration, and the crystallizer expert curve is stable , heat flux 1.0-1.1NW / m 2 , the surface of the slab is normal, the vibration marks on the surface of the slab are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com