Continuous casting crystallizer covering slag special for extra-thick slab peritectic steel and preparation method thereof

A continuous casting crystallizer and ultra-thick slab technology, applied in the field of steelmaking auxiliary materials, can solve the problems of large consumption of mold slag, transverse crack defects, prone center looseness and segregation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

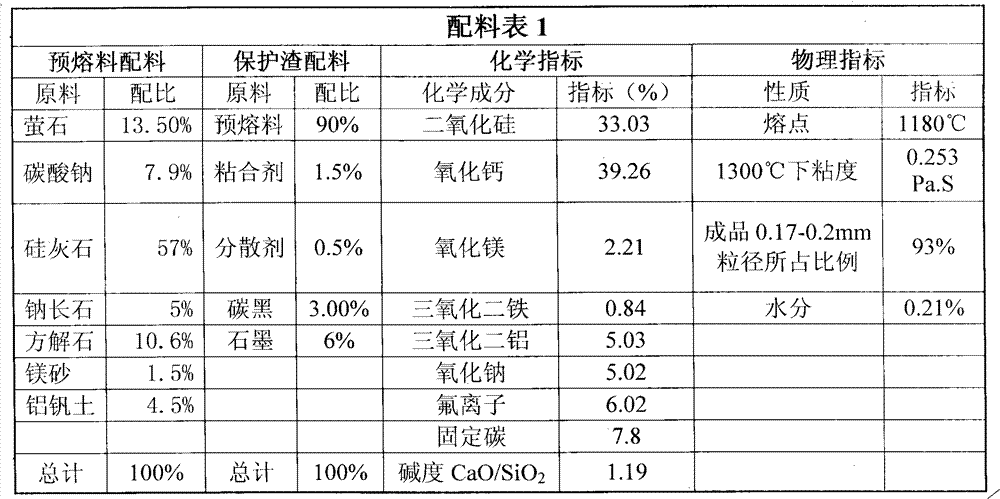

[0020] For the mold powder for continuous casting mold for extra-thick slab peritectic steel provided in this example, see ingredient list 1:

[0021]

[0022] A experiment was carried out in a steel mill company, the casting section was 400*2200mm 2 , the casting speed is 0.4-0.8m / min, the carbon content in molten steel is 0.103%, and the superheat is controlled at 20-35°C.

[0023] The entire casting process is relatively stable, the mold slag spreads well in the mold, the slag is evenly discharged, the heat transfer flux of the mold is stable, and there is no sticking alarm.

[0024] Observing the cast slab in the cold state, the surface of the cast slab is generally flat and smooth without abnormalities, the vibration marks are clear and regular, and there are no common defects of extra-thick slabs such as longitudinal cracks, transverse cracks, corner cracks, depressions, and pits.

Embodiment 2

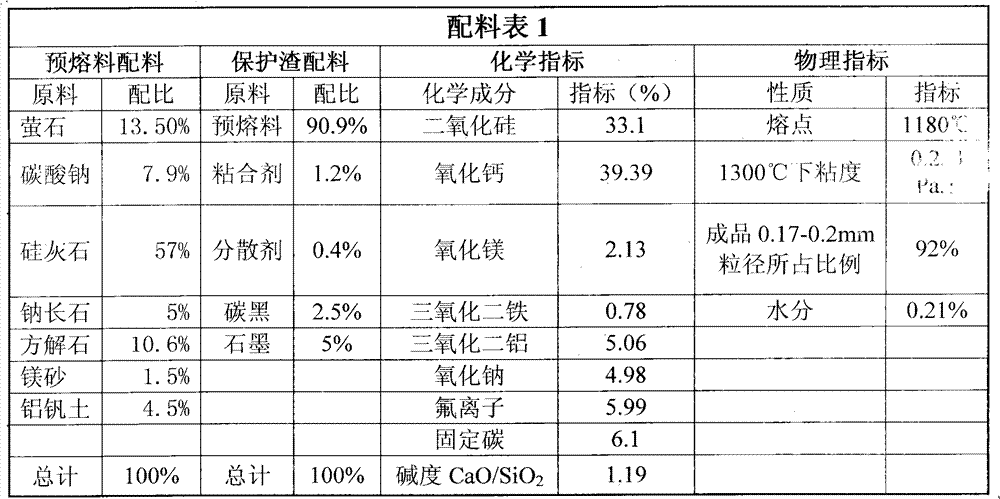

[0026] For the mold powder for continuous casting molds for extra-thick slab peritectic steel provided in this example, see ingredient list 2:

[0027]

[0028] Experiment B was carried out in a steel plant with extra thick slabs: casting section 380*2200mm 2 , casting speed 0.5 ~ 0.9m / min, carbon content in molten steel 0.129%.

[0029] The entire casting process is relatively stable, the mold slag spreads well in the mold, the slag is evenly discharged, the heat transfer flux of the mold is stable, and there is no sticking alarm.

[0030] Observing the cast slab in the cold state, the surface of the cast slab is generally flat and smooth without abnormalities, the vibration marks are clear and regular, and there are no common defects of extra-thick slabs such as longitudinal cracks, transverse cracks, corner cracks, depressions, and pits.

Embodiment 3

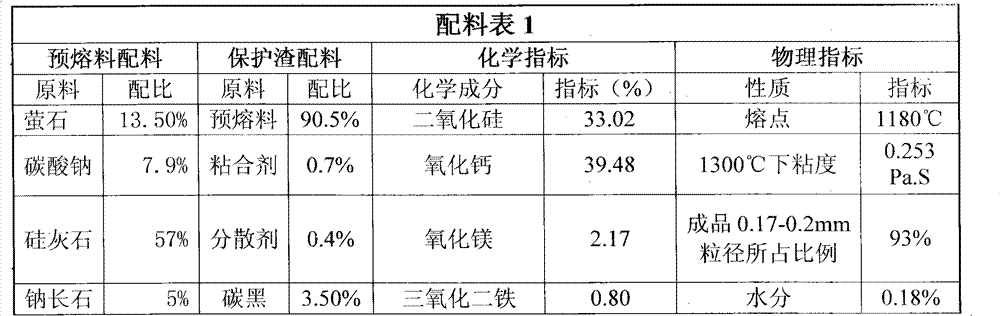

[0032] For the mold powder for continuous casting mold for extra-thick slab peritectic steel provided in this example, see ingredient list 1:

[0033]

[0034]

[0035] Experiment C was carried out in a steel factory, and the casting section was also 400*2200mm 2 , the casting speed is 0.4-0.8m / min, the carbon content in molten steel is 0.103%, and the superheat is controlled at 20-35°C.

[0036] The entire casting process is relatively stable, the mold slag spreads well in the mold, the slag is evenly discharged, the heat transfer flux of the mold is stable, and there is no sticking alarm.

[0037] Observing the cast slab in the cold state, the surface of the cast slab is generally flat and smooth without abnormalities, the vibration marks are clear and regular, and there are no common defects of extra-thick slabs such as longitudinal cracks, transverse cracks, corner cracks, depressions, and pits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com