Double-layer tundish covering agent for ultrathin belt

A covering agent and tundish technology, applied in the field of metallurgy, can solve the problems of poor thermal insulation effect of carbon-free covering agent, inability to meet the metallurgical performance of ultra-thin strips, poor insulation effect of air isolation, etc., to improve spreadability, heat insulation Good insulation effect and light stack specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

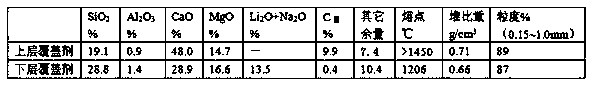

[0035] The physical and chemical indicators of the double-layer tundish covering agent for ultra-thin tape are as follows after formula design, batching, pulping, spray granulation, screening, cooling, testing, and packaging of qualified raw materials entering the factory: Table 1

[0036]

[0037] The produced products are used in the tundish of the ultra-thin strip steel production line. The steel type is low-carbon steel with a carbon content of 0.02~0.05%. The average pouring time per furnace is 82 minutes, and the average pouring speed is 69m / min.

[0038] When the ladle is opened for about 5 minutes, add 90Kg of the lower layer of the tundish covering agent, and add 120Kg of the upper layer of the tundish covering agent along with the pouring. The second furnace will add 20Kg of the lower layer and 30Kg of the upper layer according to the situation. The third and fourth furnaces each add 20Kg to the upper layer. A total of 4 furnaces of steel were poured.

[0039] Re...

Embodiment 2

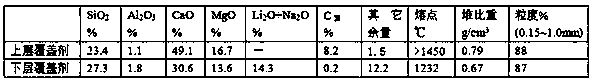

[0043] The physical and chemical indicators of the double-layer covering agent for ultra-thin tape are as follows after formula design, batching, pulping, spray granulation, screening, cooling, testing, and packaging of qualified raw materials entering the factory: Table 3

[0044]

[0045] The produced products are used in the tundish of the ultra-thin strip steel production line. The steel type is low-carbon steel with a carbon content of 0.02~0.05%. The average pouring time for each furnace is 78 minutes, and the average pouring speed is 67m / min.

[0046] When the ladle is poured for 5 minutes, add 90Kg of the lower layer of tundish covering agent, along with pouring, add 120Kg of the upper layer of tundish covering agent, add 20Kg of the lower layer and 30Kg of the upper layer in the second furnace. After the third furnace, add 20Kg to each furnace. A total of 5 furnaces were poured.

[0047] Results of use: Table 4

[0048]

[0049] After the double-layer covering...

Embodiment 3

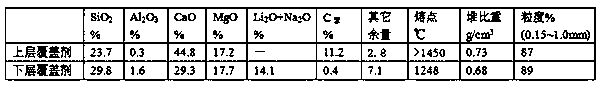

[0051] The physical and chemical indicators of the double-layer covering agent for ultra-thin tape are as follows after formula design, batching, pulping, spray granulation, screening, cooling, testing, and packaging of qualified raw materials entering the factory: Table 5

[0052]

[0053] The produced products are used in the tundish of the ultra-thin strip steel production line. The steel type is low-carbon steel with a carbon content of 0.02~0.05%. The average pouring time for each furnace is 84 minutes, and the average pouring speed is 64m / min.

[0054] When the ladle is opened for about 5 minutes, add 90Kg of the lower layer of the tundish covering agent, and add 120Kg of the upper layer of the tundish covering agent along with the pouring. The second furnace will add 20Kg of the lower layer and 30Kg of the upper layer according to the situation. After the third furnace, add 30Kg to each furnace. A total of 6 furnaces were poured.

[0055] Results of use: Table 6

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com