Negative electrode formula for improving high-temperature performance of lead-acid storage battery and preparation method of negative electrode formula

A lead-acid battery, high-temperature performance technology, applied in the direction of lead-acid batteries, battery electrodes, negative electrodes, etc., can solve the problems of high-temperature life and high water loss, and achieve the effects of prolonging high-temperature cycle life, inhibiting hydrogen evolution, and shortening cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

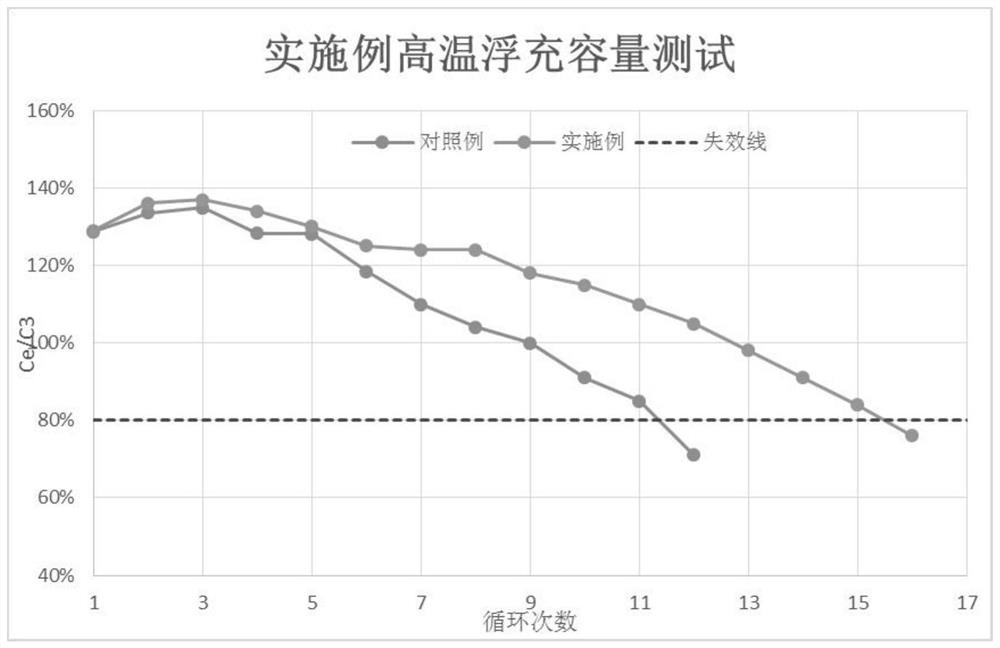

Examples

Embodiment 1

[0021] A negative electrode formula for improving the high-temperature performance of lead-acid batteries. The components in parts by weight: 100 parts of lead powder, 8 parts of dilute sulfuric acid, 9 parts of deionized water, 0.06 parts of short fibers, 0.10 parts of lignin, and 0.3 parts of humic acid part, 0.05 part of syntan, 0.8 part of barium sulfate, 0.10 part of carbon black, 0.04 part of highly conductive graphite, 0.08 part of the first hydrogen evolution inhibitor, and 0.05 part of the second hydrogen evolution inhibitor;

[0022] The concentration of dilute sulfuric acid is 50%, the particle size of carbon black is 0.3-10 μm, the particle size of high-conductivity graphite is 0.5-100 μm, and the synthetic tanning agent is NF type, which is α-naphthalenesulfonic acid formaldehyde polymer.

[0023] A method for preparing a negative electrode formula for improving the high-temperature performance of a lead-acid battery, comprising the following steps:

[0024] S1. M...

Embodiment 2

[0028] A negative electrode formula for improving the high-temperature performance of lead-acid batteries, the components according to parts by weight: 100 parts of lead powder, 11 parts of dilute sulfuric acid, 13 parts of deionized water, 0.14 parts of short fibers, 0.20 parts of lignin, and 0.45 parts of humic acid 0.1 part of syntan, 1.2 part of barium sulfate, 0.15 part of carbon black, 0.08 part of highly conductive graphite, 0.15 part of the first hydrogen evolution inhibitor, and 0.1 part of the second hydrogen evolution inhibitor;

[0029] The concentration of dilute sulfuric acid is 50%, the particle size of carbon black is 0.3-10 μm, the particle size of high-conductivity graphite is 0.5-100 μm, and the synthetic tanning agent is NF type, which is α-naphthalenesulfonic acid formaldehyde polymer.

[0030] A method for preparing a negative electrode formula for improving the high-temperature performance of a lead-acid battery, comprising the following steps:

[0031] ...

Embodiment 3

[0035] A negative electrode formula for improving the high-temperature performance of lead-acid batteries, the components according to parts by weight: 100 parts of lead powder, 9.5 parts of dilute sulfuric acid, 11 parts of deionized water, 0.10 parts of short fibers, 0.15 parts of lignin, and 0.39 parts of humic acid part, 0.075 part of syntan, 1.0 part of barium sulfate, 0.125 part of carbon black, 0.06 part of high conductivity graphite, 0.115 part of the first hydrogen evolution inhibitor, and 0.075 part of the second hydrogen evolution inhibitor;

[0036] The concentration of dilute sulfuric acid is 50%, the particle size of carbon black is 0.3-10 μm, the particle size of high-conductivity graphite is 0.5-100 μm, and the synthetic tanning agent is NF type, which is α-naphthalenesulfonic acid formaldehyde polymer.

[0037] A method for preparing a negative electrode formula for improving the high-temperature performance of a lead-acid battery, comprising the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com