Lithium ion capacitor

A capacitor and lithium ion technology, applied in the field of lithium ion capacitors, can solve the problems of not paying attention to the influence of the power characteristics of lithium ion capacitors, unable to ensure the high conductivity characteristics of the electrolyte, restricting the power characteristics of lithium ion capacitors, etc., to achieve high energy utilization Efficiency, suppressing the decay of cycle life, improving the effect of energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The positive electrode material layer is 82wt% activated carbon (the specific surface area is 1600m 2 / g) as positive electrode active material, 10wt% acetylene black as conductive agent, 8wt% PTFE as binding agent;

[0036] The negative electrode material layer uses 92wt% mesophase carbon microspheres (pre-intercalated lithium capacity of 250mAh / g) as the negative active material, 3wt% Ketjen black as the conductive agent, 2.5wt% SBR and 2.5wt% CMC as a binder;

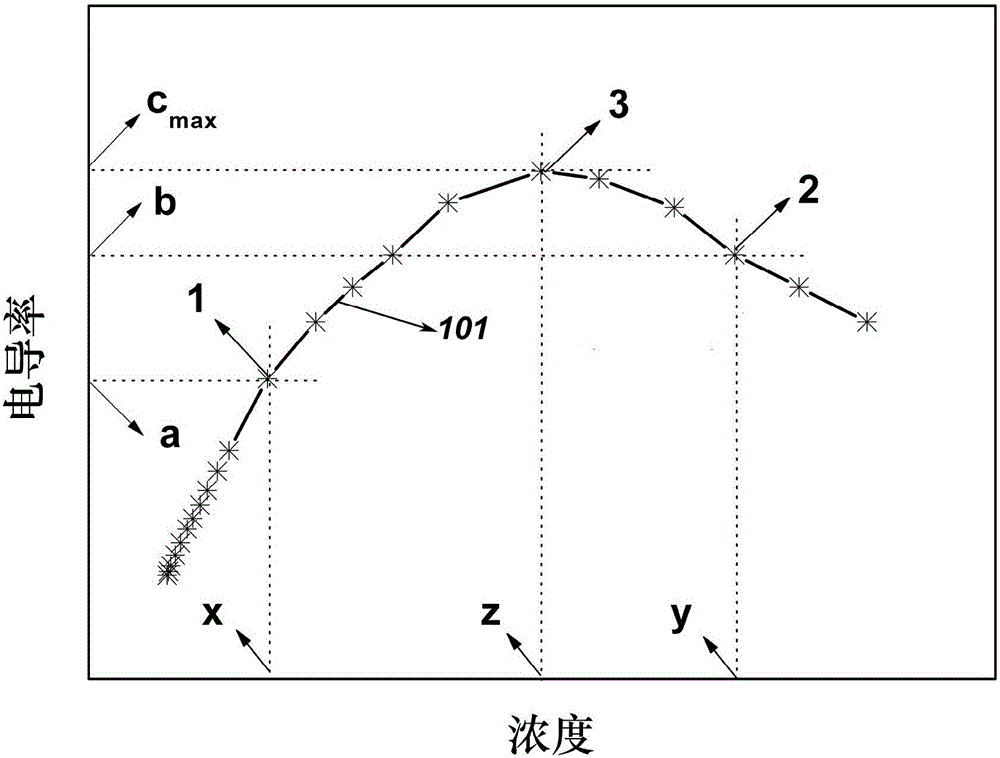

[0037] The lithium salt in the electrolyte is LiPF 6 , the solvent is EC and EMC (the volume ratio of the two is 1:1), and the maximum conductivity concentration of the electrolyte in this system is 0.75mol / L at 30°C;

[0038] Lithium-ion capacitors work at 2.0V-3.8V, the concentration of the electrolyte is 1.0mol / L at 2.0V, and 0.75mol / L at 3.8V.

Embodiment 2

[0040] Positive electrode material layer with 5wt% activated graphene (specific surface area is 3100m 2 / g) and 80wt% activated carbon (the specific surface area is 1400m 2 / g) as positive electrode active material, the acetylene black of 5wt% is as conductive agent, and the PTFE of 10wt% is as binding agent;

[0041] The negative electrode material layer uses 87wt% artificial graphite (pre-intercalated lithium capacity is 100mAh / g) as the negative electrode active material, 6wt% acetylene black as the conductive agent, and 7wt% PVDF as the binder;

[0042] The lithium salt in the electrolyte is Li(CF 3 BF 3 ), the solvent is EC, EMC and DMC (the volume ratio of the three is 5:3:2), and the maximum conductivity concentration of the electrolyte in this system is 1mol / L at 25°C;

[0043] Lithium-ion capacitors work at 2.0V-4.0V, the concentration of the electrolyte is 1.1mol / L at 2.0V, and 0.8mol / L at 4.0V.

Embodiment 3

[0045] The positive electrode material layer is carbon aerogel activated by 84wt% carbon dioxide (the specific surface area is 1886m 2 / g) as positive electrode active material, 4wt% acetylene black and 2wt% conductive graphite as conductive agent, 10wt% PTFE as binding agent;

[0046] The negative electrode material layer uses 80wt% carbon-coated lithium titanate (the carbon coating amount is 3.25%) as the negative electrode active material, 10wt% Ketjen black as the conductive agent, and 10wt% PVDF as the binding agent;

[0047] The lithium salt in the electrolyte is LiPF 6 , the solvent is PC, and the maximum conductivity concentration of the electrolyte in this system is 0.8mol / L at 25°C;

[0048] Lithium-ion capacitors work at 1.5V-2.7V, the concentration of the electrolyte is 1.0mol / L at 1.5V, and 0.7mol / L at 2.7V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com