High-entropy alloy with excellent strength and plasticity and preparation method thereof

A high-entropy alloy and plastic technology, applied in the field of high-entropy alloy and its preparation, can solve the problems of limited engineering application, limited strength improvement, low strength, etc., and achieve the effect of strength and plasticity improvement, good fracture strength and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned high-entropy alloy with excellent strong plasticity includes:

[0026] Using pure Al, pure Co, pure Cr, pure Fe and pure Ni with a purity higher than 99.9% as raw materials, the constituent elements and atomic percentages are: 18-21% Al, 1-10% Co, 15-19% Cr, 20-24% Fe, 33-41% Ni in the high-entropy alloy proportion, and the above-mentioned high-entropy alloy is prepared by arc melting.

[0027] Wherein, the arc melting process is carried out in a non-consumable vacuum arc melting furnace. And the process conditions of the arc melting process are preferably: pre-evacuation 6 × 10 -3 Pa, backfill inert gas to -0.05MPa as a protective atmosphere; the inert gas is 99.999% high-purity argon.

[0028] Further, in order to ensure uniform composition, electromagnetic stirring is added during the arc melting process, and the magnetic stirring current is 2-20A, and the melting current is 100-400A.

[0029] Furthermore, in order to ...

Embodiment 1

[0032] The constituent elements and atomic percentages of the high-entropy alloy with excellent strong plasticity in this embodiment are: 19% Al, 1% Co, 19% Cr, 20% Fe, 41% Ni.

[0033] The preparation method of the alloy comprises the following steps:

[0034] Using pure Al, pure Co, pure Cr, pure Fe, and pure Ni with a purity higher than 99.9% as raw materials, the arc melting is carried out in a non-consumable vacuum arc melting furnace, and the pre-evacuation is 6×10 -3 Pa, backfilled with high-purity argon (99.999%) to -0.05MPa as a protective atmosphere;

[0035] The arc smelting is repeated 4 to 5 times, and the alloy ingot is turned over for the next smelting after each smelting, so as to improve the compositional uniformity of the final finished ingot.

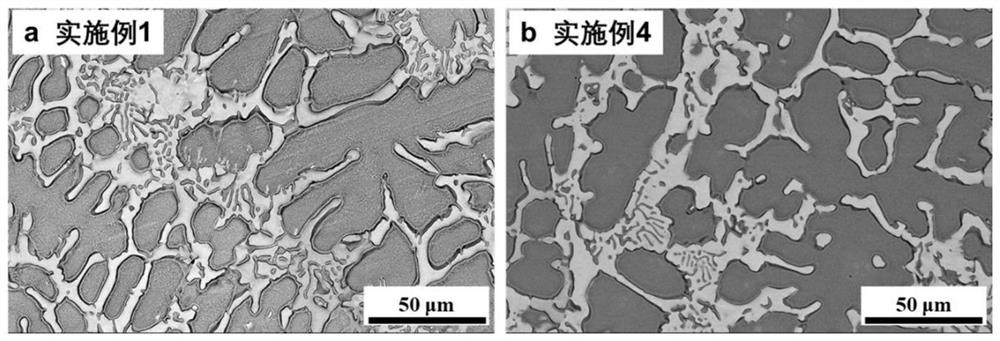

[0036] Scanning electron microscopy characterizes the initial structure of the alloy prepared in this embodiment, and the results are as attached figure 1 As shown, its structure presents primary BCC phase and inter...

Embodiment 2

[0038] The constituent elements and atomic percentages of the high-entropy alloy with excellent strong plasticity in this embodiment are: 19% Al, 5% Co, 18% Cr, 20% Fe, 38% Ni.

[0039] The preparation method of the alloy comprises the following steps:

[0040] Using pure Al, pure Co, pure Cr, pure Fe, and pure Ni with a purity higher than 99.9% as raw materials, the arc melting is carried out in a non-consumable vacuum arc melting furnace, and the pre-evacuation is 6×10 -3 Pa, backfilled with high-purity argon (99.999%) to -0.05MPa as a protective atmosphere;

[0041] The arc smelting is repeated 4 to 5 times, and the alloy ingot is turned over for the next smelting after each smelting, so as to improve the compositional uniformity of the final finished ingot.

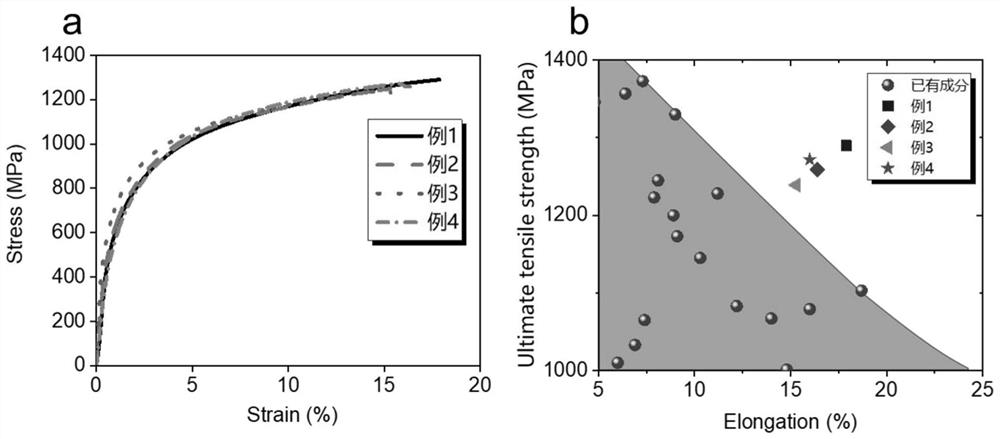

[0042]Cut the obtained alloy ingot into parallel sections of 8*2*1.5mm 3 The plate tensile specimen, the tensile rate is 1*10 -3 / s for tensile performance test, the results show that its tensile strength is 1259MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com