Method for preparing biodiesel by hydrodeoxygenation of biolipid

A technology of hydrodeoxygenation and bio-oil, which is applied in the fields of fatty acid hydrogenation, biofuel, petroleum industry, etc., can solve the problems of complex bio-oil to diesel process, easy deactivation of catalyst, economic benefits, and low product yield, and achieve good results. Economic benefits and industrial application prospects, the effect of improving hydroisomerization performance and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

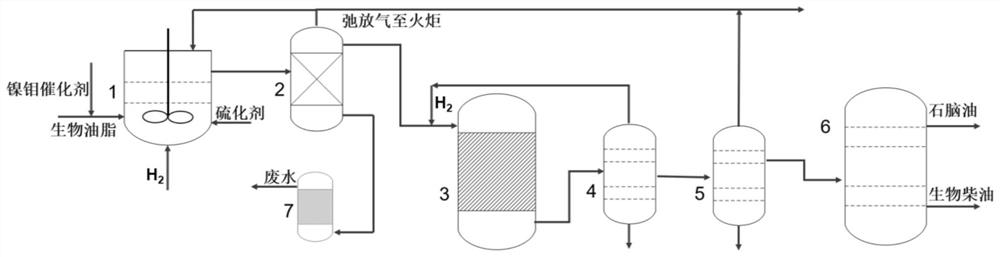

Image

Examples

Embodiment 1

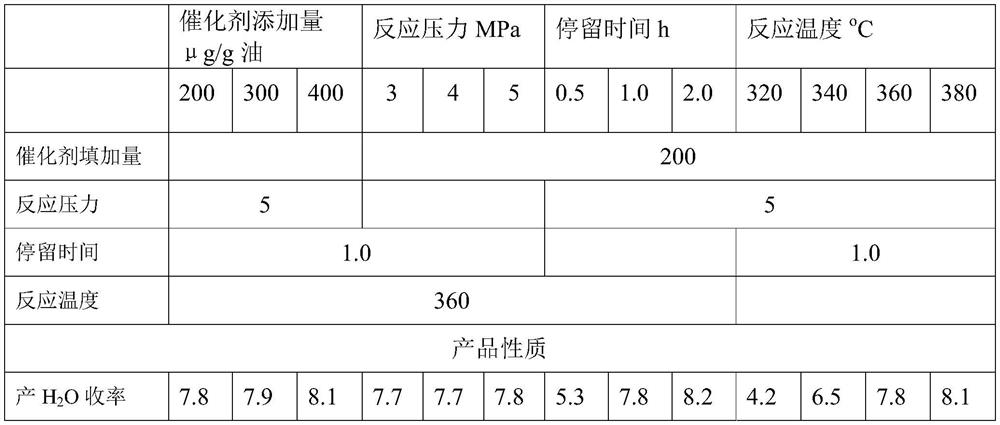

[0023] Embodiment 1: be 2% with water content, the palm oil press that metal ion content is 500ppm, total acid value 160mgKOH / g is biological grease raw material, with nickel nitrate and ammonium molybdate as metal precursor, with MF dispersant as Hydrophilic surfactant, Ni-Mo water-soluble hydrodeoxygenation catalyst prepared by hydrothermal method. Under reaction conditions: temperature 320-380°C, pressure 3-5MPa, residence time 0.5-2h, the product is separated into water phase and oil phase after ultrasonic demulsification, and its yield is measured. Table 1 below shows the impact of different reaction conditions on the reaction results.

[0024]

[0025] It can be seen from the table that the addition amount of Ni-Mo water-soluble hydrodeoxygenation catalyst and the reaction pressure have little effect on the effect of hydrodeoxygenation. Raising the reaction temperature is helpful to the hydrodeoxygenation reaction. The higher the temperature is, the higher the temper...

Embodiment 2

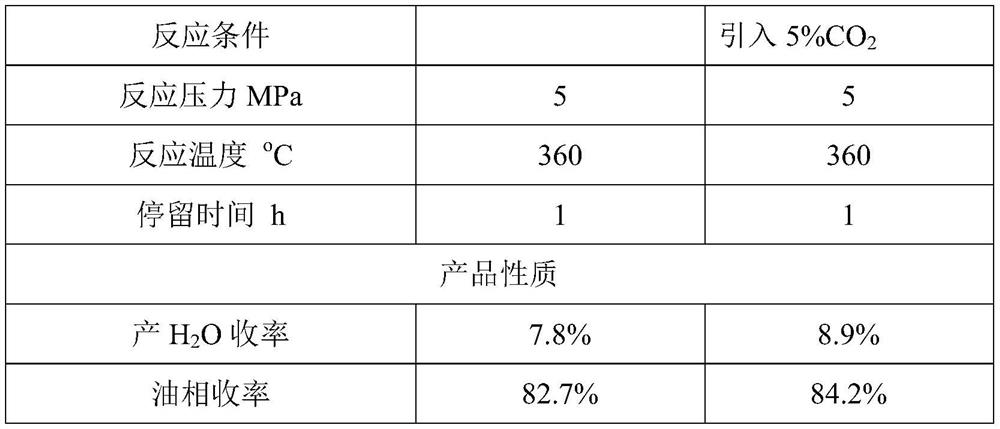

[0026] Embodiment 2: be 2% with water content, the palm oil press that metal ion content is 500ppm, total acid value 160mgKOH / g is biological oil raw material, with nickel nitrate and ammonium molybdate as metal precursor, with MF dispersant as Hydrophilic surfactant, Ni-Mo water-soluble hydrodeoxygenation catalyst prepared by hydrothermal method, the catalyst addition amount is 200μg / g oil. Under the reaction conditions: temperature 360°C, pressure 5MPa, residence time 1h, the addition of CO 2 Effect on Hydrodeoxygenation. See Table 2 below for supplemental CO 2 influence on the outcome of the reaction.

[0027]

[0028] It can be seen from the table that when 5% CO is introduced 2 Finally, the decarboxylation reaction is suppressed, the direct hydrodeoxygenation reaction is improved, and the oil yield is increased by 1.5%.

Embodiment 3

[0029] Embodiment 3: add CO with embodiment 2 2 The produced oil phase product is used as a raw material, and a refined catalyst containing 2% ZSM-48 is used as a carrier, in which NiO accounts for 6%, MoO 3 Accounted for 15%, the rest is the carrier. Reaction conditions: temperature 280-340°C, pressure 3-5MPa, space velocity 0.5-2.0h -1 , The hydrogen-to-oil ratio is 200-600:1, and the influence of the reaction on hydrofining is investigated. See the influence of the reaction results in Table 3 below.

[0030]

[0031] It can be seen from the table that high temperature, low space velocity, and large hydrogen-to-oil ratio are beneficial to the occurrence of hydrodeoxygenation and isomerization reactions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com