Waterborne alkyd resin and preparation method thereof

A technology of water-based alkyd resin and epoxy resin, which is applied in the field of resin materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The second aspect of the embodiment of the present application provides a preparation method of water-based alkyd resin, the preparation method comprising the following steps:

[0042] S01: Provide the raw materials of the water-based alkyd resin of the embodiment of the present application, and divide the catalyst into two parts;

[0043] S02: Mix epoxy resin, polyol, organic acid, polyurethane polyol and a catalyst in the reflux solvent, perform the first reaction, and then remove the solvent to obtain the first reaction product;

[0044] S03: mixing the first reaction product with acrylic acid monomer and another part of catalyst, performing a second reaction to obtain a second reaction product;

[0045] S04: Dilute the second reaction product with a diluent solvent, and then filter to obtain a water-based alkyd resin.

[0046] The preparation method of the water-based alkyd resin provided in the embodiment of the present application, the polyurethane polyol formed ...

Embodiment 1

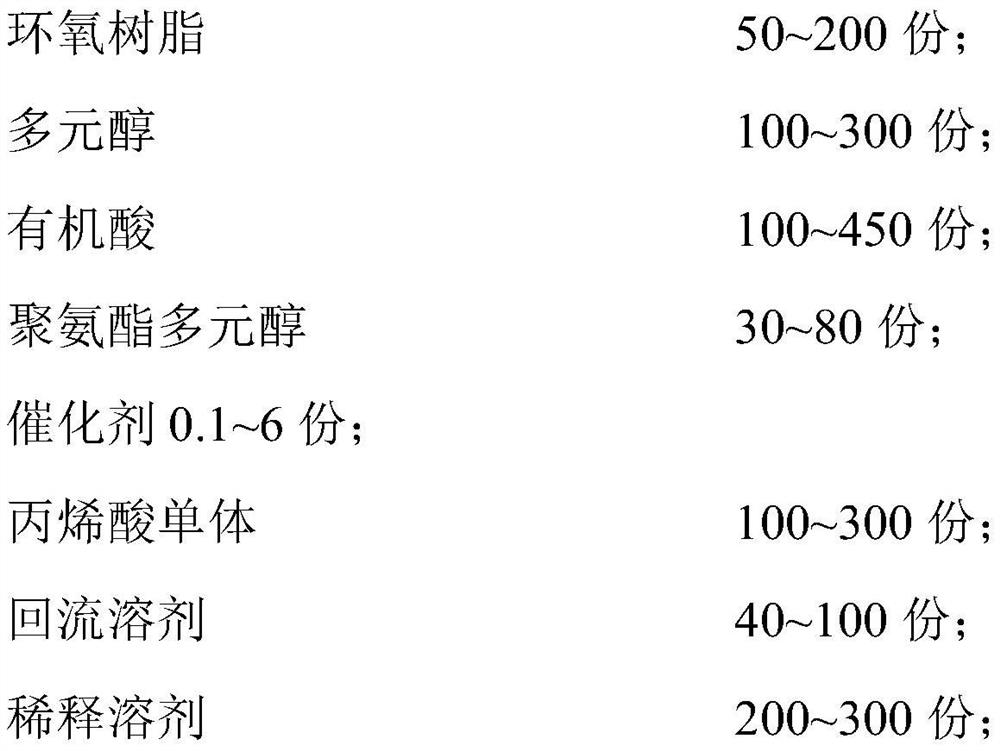

[0056] A kind of waterborne alkyd resin, its preparation raw material comprises the component of following parts by weight:

[0057]

[0058] Wherein, the epoxy resin is a mixture of 50 parts of epoxy resin E-51 and 60 parts of epoxy resin E-20. The polyol was a mixture of 30 parts neopentyl glycol and 150 parts trimethylolpropane. The organic acid was a mixture of 15 parts benzoic acid, 60 parts isophthalic acid, 45 parts phthalic anhydride and 130 parts soyoleic acid. The catalyst was a mixture of 0.4 parts dibutyltin dilaurate and 0.2 parts t-butyl peroxide. 60 parts of polyurethane polyol, obtained by polymerization of triphenylmethane triisocyanate, dicyclohexylmethane-4,4'-diisocyanate and polycarbonate diol in a mass ratio of 20:2:210. The acrylic monomer was a mixture of 60 parts styrene, 100 parts methyl methacrylate, 20 parts divinylbenzene, 30 parts methacrylic acid and 50 parts butyl acrylate. The reflux solvent was 60 parts xylene. The dilution solvent is a...

Embodiment 2

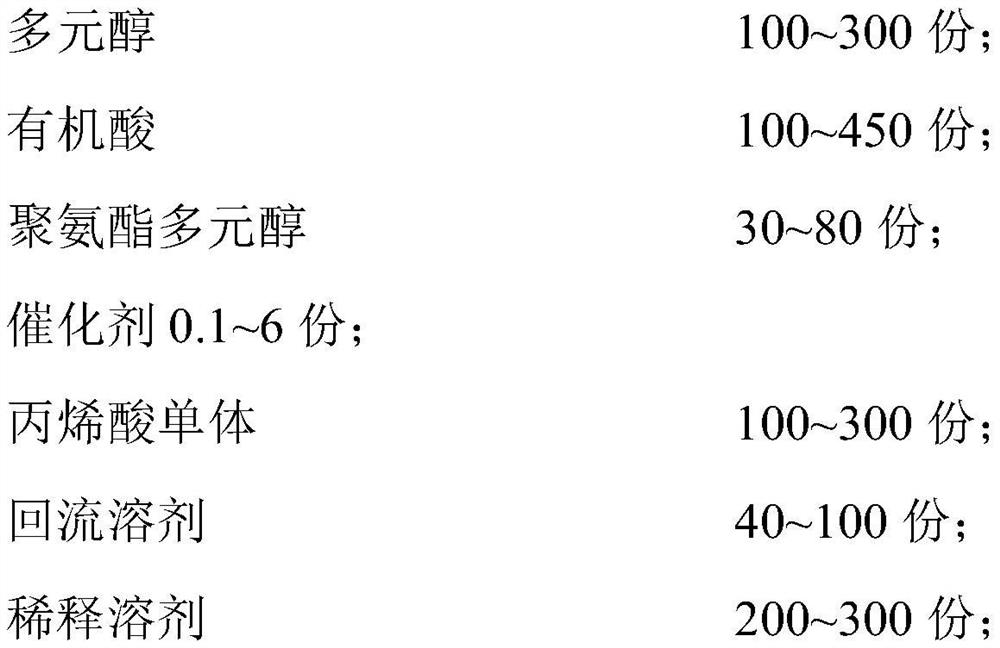

[0065] A kind of waterborne alkyd resin, its preparation raw material comprises the component of following parts by weight:

[0066]

[0067] Wherein, the epoxy resin is a mixture of 30 parts of epoxy resin E-51 and 50 parts of epoxy resin E-20. The polyol was a mixture of 60 parts pentaerythritol and 80 parts trimethylolpropane. The organic acid was a mixture of 20 parts phthalic anhydride, 60 parts isophthalic acid, 20 parts adipic acid and 150 parts tunglinoleic acid. The catalyst was a mixture of 0.4 parts of dibutyltin dilaurate and 0.1 part of tert-butyl peroxide, divided into two equal parts. 80 parts of polyurethane polyol, obtained by polymerization of triphenylmethane triisocyanate, dicyclohexylmethane-4,4'-diisocyanate and polycarbonate diol at a mass ratio of 15:2:230. The acrylic monomer was a mixture of 30 parts styrene, 60 parts methyl methacrylate, 45 parts isobornyl acrylate, 15 parts methacrylic acid and 70 parts vinyltrimethoxysilane. The reflux solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com