Welding integration technology of medium- and high-temperature thermoelectric power generation devices and manufacturing tool

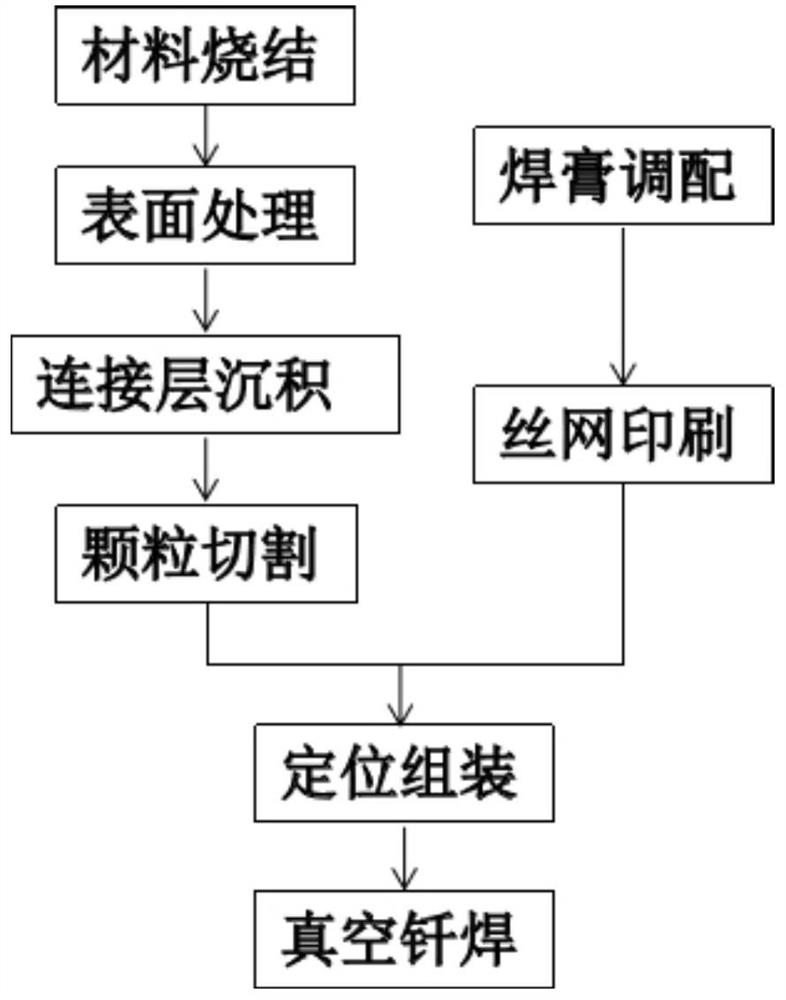

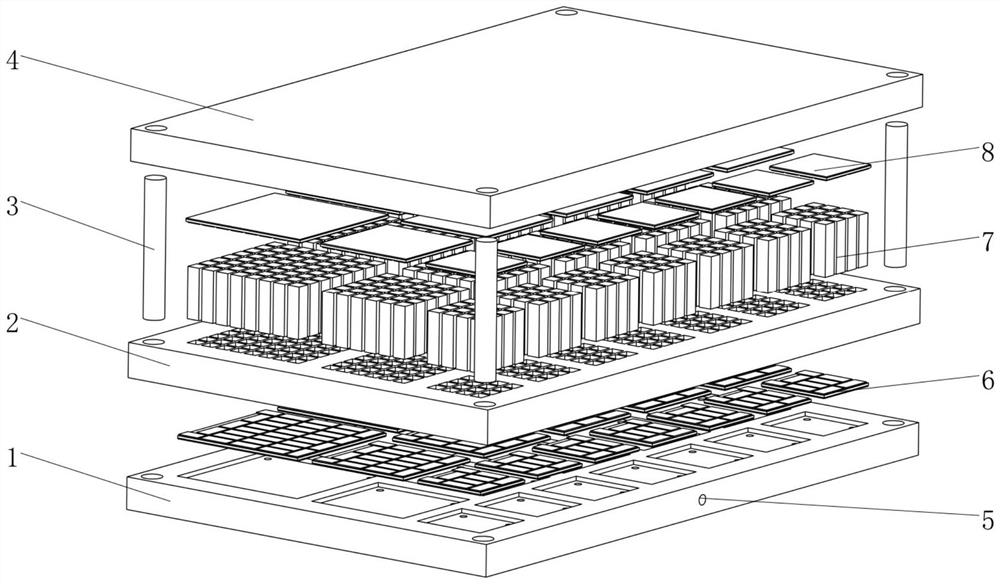

A technology for thermoelectric power generation and welding tools, which is applied in the manufacture/processing of thermoelectric devices, manufacturing tools, welding equipment, etc., can solve the problems of poor dimensional consistency of formed devices, excessive processing tolerances, and low local welding strength, and achieve simplification. The complexity of assembly and the difficulty of positioning, reducing the welding integration temperature, and ensuring the effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

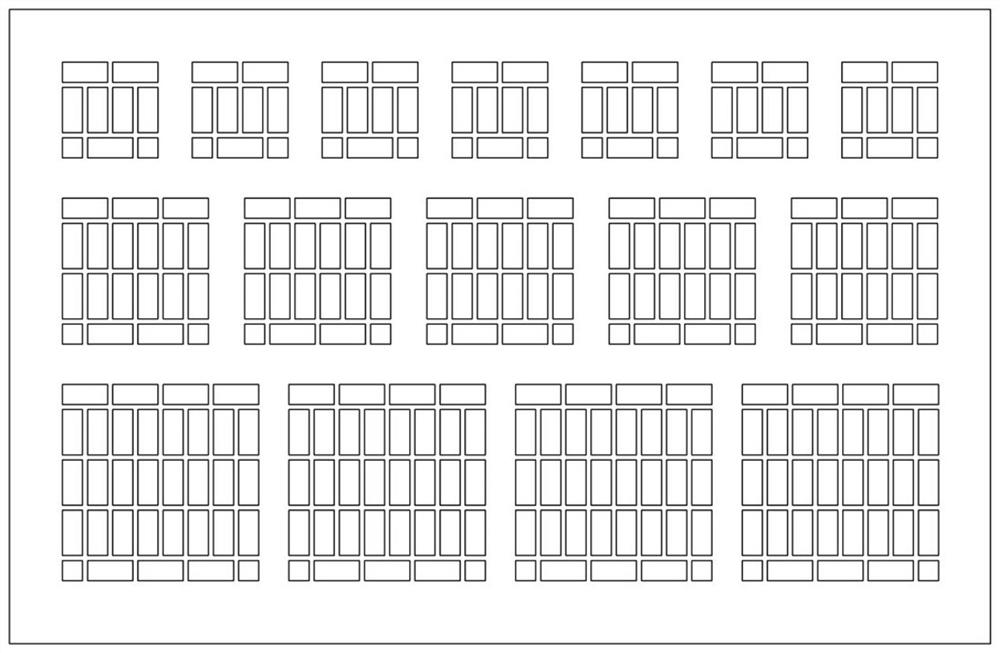

[0051] The N-type and P-type skutterudite materials were hot-pressed and sintered at 650°C and 550°C, respectively, with a pressure of 60MPa, kept for 30 minutes and sintered densely, and the sintered density was 95%; then the double-sided surfaces were thinned and polished to a thickness of 8mm. After dilute hydrochloric acid corrosion, sputter Nb and Ni metal connection layers in sequence under magnetron sputtering, with a thickness of 3 microns and 5 microns respectively, and then cut them into thermoelectric particles 7 with a size of 4mm*4mm*8mm; prepare CuAgZn solder paste until the viscosity is 800Kcps, using a steel sheet with a thickness of 0.01mm, the solder paste is evenly applied to the aluminum oxide substrate with a size of 20mm*20mm by screen printing to obtain the upper substrate 8( Figure 3b Shown is the stencil used for screen printing on the upper substrate 6) and the lower substrate 6 ( Figure 3a Shown is the stencil mesh used for screen printing of the l...

Embodiment 2

[0058] N-type Zr 0.5 f 0.5 NiSn 0.98 Sb 0.02 and P-type Nb 0.8 Ti 0.2 The FeSb material was sintered by spark plasma at 850°C and 850°C respectively, the pressure was 60MPa, and the temperature was kept for 15 minutes for sintering and density, and the sintering density was 95%. 2 microns and 5 microns, and then cut into thermoelectric particles of 4mm*4mm*12mm; the CuAgTi solder paste was adjusted to a viscosity of 1600Kcps, and it was printed on a stencil with a thickness of 0.3mm to a nitrided particle with a size of 20mm*20mm. On the aluminum substrate, the thermoelectric particles are positioned and brazed under pressure at 850°C with a pressure of 5MPa to obtain a half-Heusler power generation device in the high temperature region.

[0059] The structure and installation of the welding tool in this embodiment are the same as those in Embodiment 1.

[0060] For the power generation performance data of the high-temperature region half-Heusler power generation device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com