Epoxypropane material flow separation method, epoxidation reaction product separation method and propylene epoxidation method

A technology of propylene oxide and separation method, applied in the direction of organic chemistry and the like, can solve the problems of increasing the construction cost and operating cost of an extractive distillation column, reducing the volumetric efficiency of the extractive distillation column, increasing the amount of waste water generated, etc., and improving the low temperature heat source. Effectiveness of utilization efficiency, lower construction and operating costs, and reduced liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

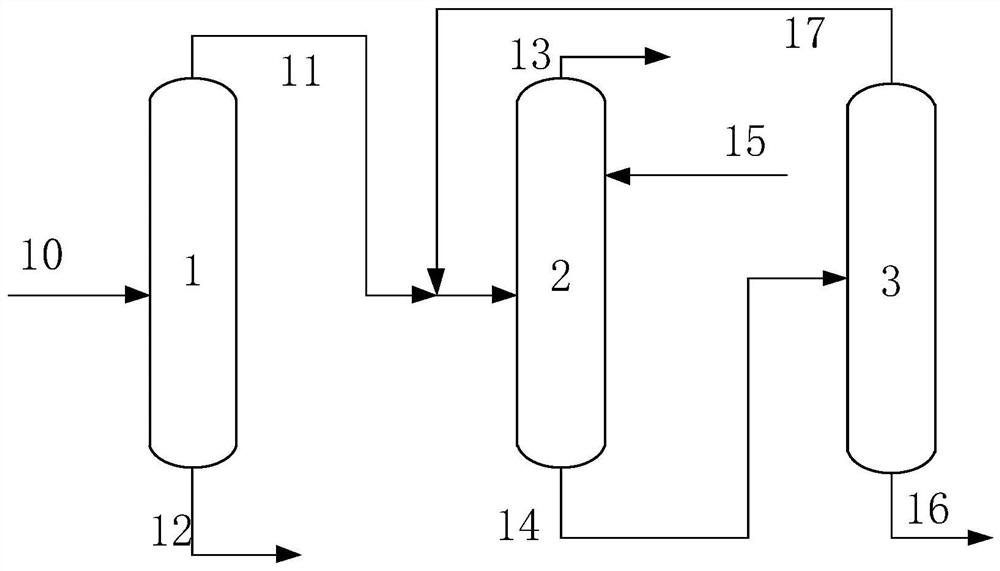

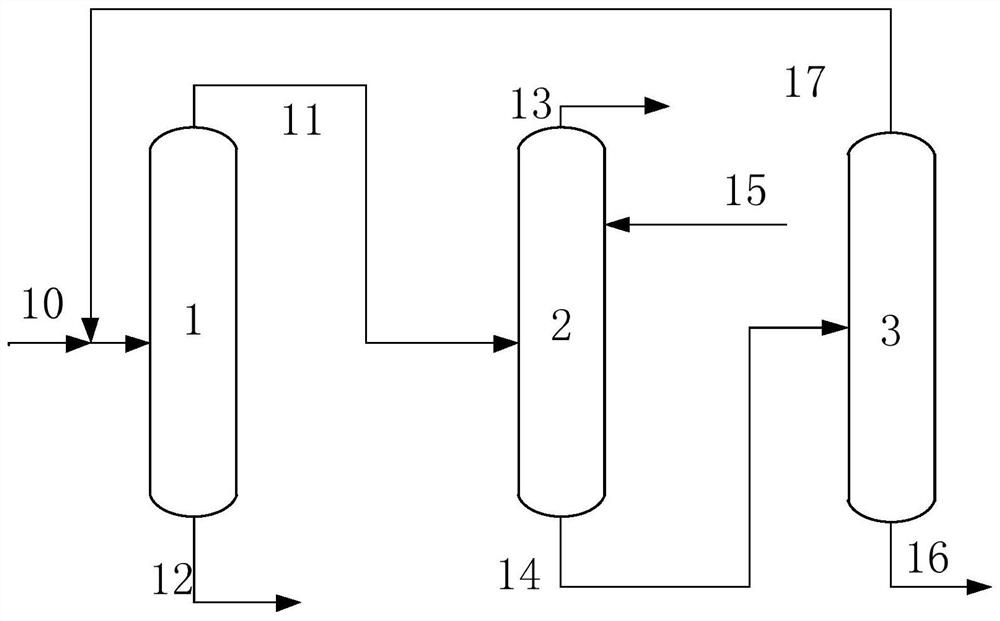

Image

Examples

Embodiment 1

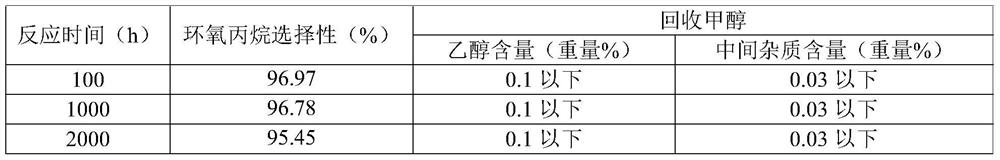

[0147] (1) methyl alcohol is mixed with propylene and hydrogen peroxide (hydrogen peroxide content is 50% by weight) according to propylene: hydrogen peroxide: the mol ratio of methyl alcohol is 2:1:8, and mixture is fed into and packed with epoxidation catalyst ( The model purchased from Sinopec Catalyst Changling Branch Company is the epoxidation catalyst of HPO-1, which is a hollow titanium-silicon molecular sieve catalyst) in the tubular fixed-bed reactor (diameter φ25mm inside the pipe, length is 4m) , contact with the epoxidation reaction catalyst to carry out the epoxidation reaction, wherein the temperature in the fixed bed reactor is controlled to be 45°C, and the liquid hourly volume space velocity is 0.2h in terms of hydrogen peroxide -1 , an epoxidation reaction product stream is obtained from the top of the epoxidation reactor. In the epoxidation reaction product stream, the content of methanol was 62.2% by weight, the content of propylene oxide was 13.2% by weigh...

Embodiment 2

[0184] The difference between embodiment 2 and embodiment 1 is that in step (3-1), the rectification condition of the methanol rectification tower is adjusted: the reflux ratio is 1.2.

[0185] In crude propylene oxide, the content of propylene oxide was 96.4% by weight, the content of methanol was 3.4% by weight, the content of ester was 0.03% by weight, the content of aldehyde was 0.10% by weight, and the content of acetone was 0.03% by weight.

[0186] In the finally obtained propylene oxide product, the content of propylene oxide is 99.98% by weight, the weight content of methanol is 19ppm, the weight content of ester is 7ppm, the weight content of aldehyde is 23ppm, and the weight content of acetone is 4ppm. The recovery of propylene oxide relative to the propylene oxide in the epoxidation reaction product stream was 99.8%.

Embodiment 3

[0192] The difference between embodiment 3 and embodiment 1 is: the feed rate of extractant water in step (4-1) is 9.3kg / h.

[0193] In the propylene oxide product that finally obtains, the content of propylene oxide is 99.99% by weight, and the weight content of methyl alcohol is 1ppm, and the weight content of ester is 4ppm, and the weight content of aldehyde is 18ppm, and the weight content of acetone is 1ppm, from the second The tower bottom effluent of the methanol rectification tower and the tower bottom effluent of the ethanol rectification tower are output as waste water into the waste water treatment unit for treatment, wherein the amount of waste water is 50.5 kg / h. The recovery of propylene oxide relative to the propylene oxide in the epoxidation reaction product stream was 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com