Heat pump coupling biological heat drying system and method

A biothermal and biodrying technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of organic matter volatilization, low dehumidification efficiency of closed systems, and odorous gas pollution to the environment, and achieves simplified structure, The effect of improving heat utilization efficiency and reducing construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

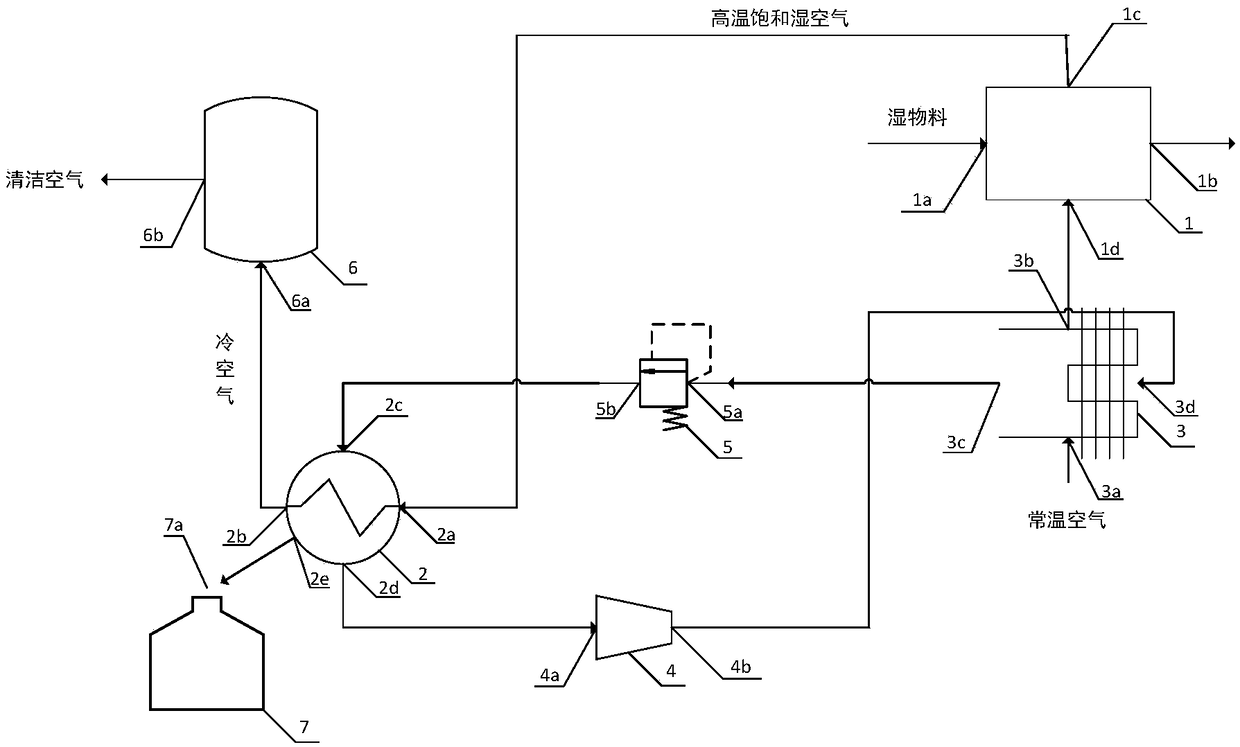

[0038] A heat pump coupled bio-heat drying system, comprising a bio-heat drying device 1, an evaporation-condensation coupling heat exchange device 2, a heating-condensation coupling device 3, a gas booster 4, an expansion valve 5, a biological filter bed device 6 and condensed water collection device 7;

[0039] The biological heat drying device 1 is provided with a wet material inlet 1a, a dry material outlet 1b, a hot air inlet 1d and a hot and humid air outlet 1c, and the hot and humid air outlet 1c is connected to the hot and humid air inlet 2a of the evaporation-condensation coupling heat exchange device 2;

[0040] The evaporation-condensation coupled heat exchange device 2 is provided with hot and humid air inlet 2a, cold air outlet 2b, low temperature and low pressure liquid working medium inlet 2c, low temperature and low pressure gaseous working medium outlet 2d and condensed water outlet 2e, cold air outlet 2b and biological filter The cold air inlet 6a of the bed de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com